Understanding Rexroth Poppet Valves

Rexroth Poppet Valves are critical components in hydraulic systems, known for their reliability and efficiency in flow control. These valves are designed to manage the direction and flow of hydraulic fluid, making them indispensable in various industrial applications, including manufacturing and automation. Their robust construction ensures longevity and consistent performance under demanding conditions.

Introduction to Rexroth Poppet Valves

Rexroth Poppet Valves are essential in the realm of hydraulic systems, providing precise control over the flow and direction of hydraulic fluids. These valves are renowned for their durability and efficiency, making them a staple in industries such as manufacturing, automation, and heavy machinery. As demand for reliable hydraulic components grows, understanding the function and benefits of Rexroth Poppet Valves becomes increasingly important. This introduction explores the significance of these valves in hydraulic systems and highlights their role in enhancing operational efficiency and reliability.

Design and Functionality

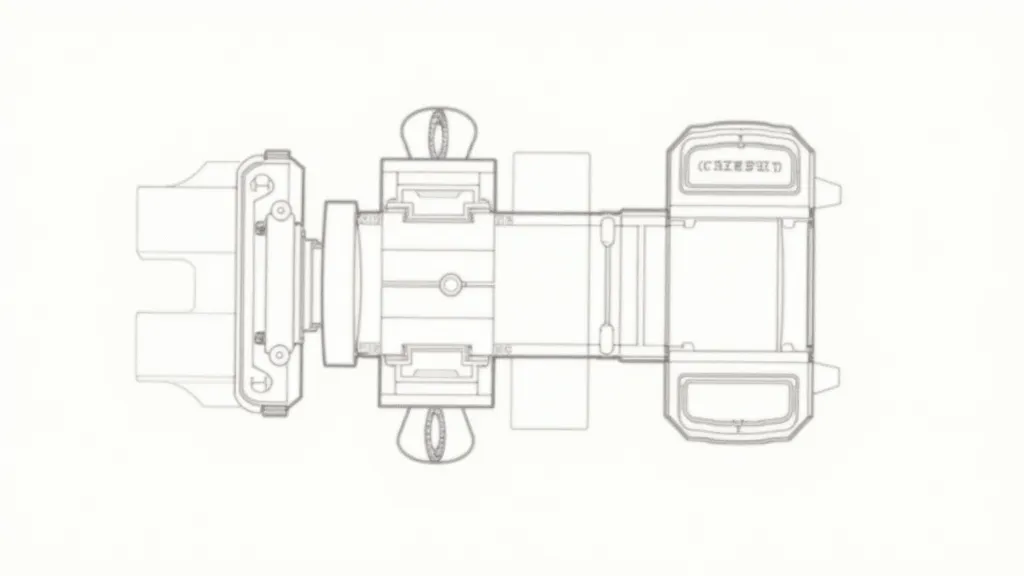

The design of Rexroth Poppet Valves is characterized by their robust construction and high performance. These valves operate by using a poppet mechanism to open or close the flow path of the hydraulic fluid, depending on the system's requirements. The poppet, typically a rounded or conical component, is pressed against a seat to create a seal, ensuring that the hydraulic fluid cannot escape when the valve is closed. This mechanism ensures a tight seal when closed, preventing leakage and maintaining system pressure, which is crucial for optimal hydraulic system performance.

In addition to their sealing capability, Rexroth Poppet Valves are designed to handle a wide range of pressures and flow rates, making them suitable for various applications. The materials used in their construction, such as high-strength alloys and composites, contribute to their ability to withstand extreme conditions while maintaining efficiency. By understanding the design and functionality of these valves, engineers and technicians can better appreciate their value in hydraulic systems.

Advantages of Using Rexroth Poppet Valves

- Reliability: The design of Rexroth Poppet Valves ensures consistent performance even under high pressure and demanding conditions. Their robust nature minimizes the risk of failure, which is critical in industrial operations where downtime can lead to significant losses.

- Efficiency: These valves provide precise flow control, enhancing the overall efficiency of hydraulic systems. By allowing for accurate adjustment of fluid flow rates, they enable operators to optimize machinery performance and reduce energy consumption.

- Durability: Made from high-quality materials, Rexroth Poppet Valves offer longevity and reduced maintenance needs. Their resistance to wear and tear translates to lower operational costs over time, making them a cost-effective solution for various applications.

- Versatility: Rexroth Poppet Valves can be utilized in a wide array of applications, from simple hydraulic circuits to complex industrial machinery. This versatility allows for seamless integration into existing systems, enhancing their functionality and adaptability.

- Compact Design: The compact nature of Rexroth Poppet Valves allows for easy installation in tight spaces, which is often a necessity in modern machinery design. This feature facilitates the incorporation of hydraulic systems into diverse applications without compromising performance.

Applications in Various Industries

Rexroth Poppet Valves are versatile and find applications across multiple industries. In manufacturing, they are used in hydraulic presses and injection molding machines, where precise control of hydraulic fluid is required for effective operation. Their ability to quickly open and close allows for rapid cycle times, enhancing productivity in manufacturing processes.

In the automation sector, these valves play a crucial role in controlling actuators and other hydraulic equipment. By regulating the flow and pressure of hydraulic fluid, Rexroth Poppet Valves ensure that automation systems function smoothly and efficiently, allowing for greater precision in tasks such as robotic movements and material handling.

Construction and heavy machinery also benefit from the use of Rexroth Poppet Valves. These valves are essential in equipment such as excavators, bulldozers, and cranes, where they help control hydraulic functions such as lifting and digging. Their robust design allows them to withstand the harsh conditions often encountered on construction sites, ensuring reliable performance even in challenging environments.

Moreover, the automotive industry employs Rexroth Poppet Valves in various applications, including hydraulic braking systems and power steering. This further demonstrates the versatility and critical role these valves play in enhancing safety and performance in vehicles.

Comparison Table

| Feature | Rexroth Poppet Valve | Other Valves |

|---|---|---|

| Performance Under Pressure | High | Variable |

| Durability | Long-lasting | Depends on Material |

| Maintenance Needs | Low | Moderate to High |

| Response Time | Fast | Slower |

| Sealing Capability | Excellent | Varies |

FAQs

What makes Rexroth Poppet Valves unique?

Rexroth Poppet Valves are unique due to their reliable sealing mechanism and ability to handle high-pressure environments, making them ideal for demanding applications. Their design allows for quick actuation and precise flow control, setting them apart from other types of valves in the market.

Are Rexroth Poppet Valves suitable for all hydraulic systems?

While they are versatile, it's important to assess the specific requirements of your hydraulic system to ensure compatibility and optimal performance. Factors such as flow rate, pressure levels, and the type of hydraulic fluid used should all be considered when selecting Rexroth Poppet Valves for a given application.

How often should Rexroth Poppet Valves be maintained?

These valves require minimal maintenance, but regular inspections are recommended to ensure they remain in optimal working condition. It is advisable to check for signs of wear, leakage, or any other abnormalities that could affect performance. Additionally, keeping the hydraulic fluid clean and free from contaminants will help prolong the life of the valves.

Installation Considerations

Proper installation of Rexroth Poppet Valves is crucial to achieving optimal performance and longevity. When installing these valves, there are several considerations to keep in mind:

- Orientation: Ensure that the valves are installed in the correct orientation as specified by the manufacturer. Incorrect orientation can lead to improper functioning and increased risk of failure.

- Pressure Ratings: Verify that the selected valve can handle the pressure specifications of your hydraulic system. Installing a valve with inadequate pressure ratings can result in catastrophic failure and damage to the system.

- Fluid Compatibility: Check that the materials used in the valve are compatible with the hydraulic fluid being utilized. Chemical reactions between incompatible materials and fluids can degrade valve performance and lifespan.

- Sealing and Connections: Ensure that all connections are secure and that proper sealing techniques are employed to prevent leaks. Utilizing the appropriate seals and fittings will enhance the integrity of the hydraulic system.

- Testing: After installation, conduct thorough testing to confirm that the valves are operating correctly. Monitoring the system for any signs of irregularities can help identify potential issues before they escalate.

Maintenance Tips for Rexroth Poppet Valves

To ensure the longevity and reliability of Rexroth Poppet Valves, regular maintenance practices should be implemented. Here are some essential maintenance tips:

- Regular Inspections: Schedule routine inspections to check for any signs of wear, leakage, or damage. Early detection of issues can prevent costly repairs and downtime.

- Fluid Quality Monitoring: Maintain clean hydraulic fluid by regularly checking for contaminants. Dirty or degraded fluid can negatively impact valve performance and lead to premature wear.

- Seal Checks: Inspect seals for integrity and signs of degradation. Replacing worn or damaged seals promptly will help maintain pressure and prevent leaks.

- Pressure Testing: Conduct pressure tests to ensure that the valves are functioning correctly under operating conditions. This testing should be part of the regular maintenance routine to confirm valve performance.

- Documentation: Keep detailed maintenance records to track the history of inspections, repairs, and part replacements. This documentation can help in planning future maintenance and identifying recurring issues.

Case Studies of Rexroth Poppet Valve Applications

Understanding the practical applications of Rexroth Poppet Valves can provide insights into their effectiveness and versatility. Below are a few case studies showcasing their success in various industries:

Case Study 1: Automotive Industry

In a major automotive manufacturing facility, Rexroth Poppet Valves were integrated into the hydraulic systems of robotic arms used in assembly lines. The precise flow control provided by these valves allowed for smooth and accurate movements of the robotic arms, which are critical for tasks such as welding and painting. The implementation of Rexroth Poppet Valves resulted in a 15% increase in production efficiency and a significant reduction in energy consumption, demonstrating their effectiveness in enhancing automation.

Case Study 2: Construction Equipment

A construction company faced challenges with hydraulic leaks in their heavy machinery, leading to increased maintenance costs and downtime. They decided to replace their existing valves with Rexroth Poppet Valves, which are designed for high-pressure applications and robust sealing capabilities. After installation, the company reported a 30% decrease in maintenance needs and a noticeable improvement in the reliability of their equipment. This case highlights the durability and efficiency of Rexroth Poppet Valves in harsh environments.

Case Study 3: Manufacturing Presses

In a manufacturing plant specializing in metal forming, the hydraulic presses were experiencing inconsistencies in pressure control, which affected product quality. By upgrading to Rexroth Poppet Valves, the plant was able to achieve better control over the hydraulic fluid, resulting in uniform pressure application across the presses. This upgrade not only improved product quality but also increased the overall throughput of the production line by 20%. The case exemplifies how Rexroth Poppet Valves can enhance performance in critical manufacturing processes.

The Future of Rexroth Poppet Valves

As technology advances, so too does the design and functionality of hydraulic components, including Rexroth Poppet Valves. Future developments may focus on incorporating smart technologies, such as sensors and IoT connectivity, to allow for real-time monitoring and diagnostics. This integration could lead to predictive maintenance capabilities, where potential issues are identified before they impact operations, further enhancing the reliability and efficiency of hydraulic systems.

Additionally, ongoing research into new materials and manufacturing processes may result in even more durable and efficient valve designs. The evolution of Rexroth Poppet Valves will likely continue to align with industry trends towards sustainability, with a focus on reducing energy consumption and minimizing environmental impact.

In conclusion, Rexroth Poppet Valves represent a critical component in hydraulic systems, offering reliability, durability, and efficiency. Their diverse applications across various industries underscore their importance. Understanding their functionality and advantages can aid in making informed decisions when selecting components for hydraulic systems, ensuring enhanced performance and longevity. As technology continues to evolve, the role of Rexroth Poppet Valves is poised to grow, further solidifying their place as indispensable elements in modern hydraulic applications.