Understanding Stauff Filters in Industry

Stauff Filters are integral components in hydraulic and lubrication systems, known for their efficiency in filtering contaminants to ensure machinery longevity and performance. This article delves into their design, applications, and benefits, providing a comprehensive understanding for professionals looking to enhance system reliability and efficiency.

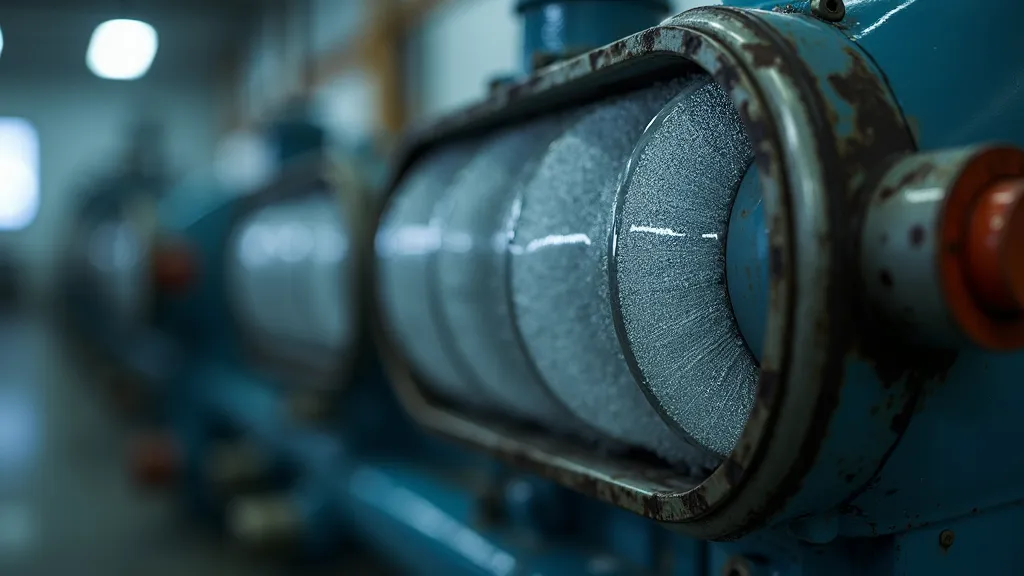

Introduction to Stauff Filters

Stauff Filters play a crucial role in maintaining the efficiency and longevity of hydraulic and lubrication systems. These filters are engineered to remove contaminants from fluids, ensuring that machinery operates smoothly and without unnecessary wear. This article offers an in-depth exploration of the Stauff Filter, its benefits, and its applications in various industries. Understanding the importance of filtration in hydraulic systems is essential, as contamination can lead to severe operational issues, including equipment failure and increased maintenance costs. As industries strive for efficiency and reliability, Stauff Filters emerge as a cornerstone of modern hydraulic and lubrication technology.

Design and Functionality

Stauff Filters are designed with precision to meet the high standards required in industrial applications. They feature robust construction to withstand harsh conditions and provide reliable filtration. The filters are available in a variety of configurations, including suction, pressure, and return line filters, each tailored to specific system needs. Their primary function is to trap and hold dirt, metal shavings, and other particulates that could compromise system integrity.

The design of Stauff Filters incorporates advanced materials and technologies that enhance their performance. For example, the filter media is often made from high-quality synthetic fibers that offer superior dirt-holding capacity and longer service life compared to standard filter materials. Additionally, many Stauff Filters feature a multi-layered design that allows for effective filtration of both coarse and fine particles, making them highly efficient in diverse applications.

Furthermore, Stauff has invested in the development of filter elements that can be easily replaced, ensuring minimal downtime during maintenance. The filters are also designed with user-friendly features, such as built-in differential pressure indicators that signal when a filter needs to be replaced, thus simplifying maintenance procedures and enhancing operational efficiency.

Applications of Stauff Filters

These filters are widely used across multiple sectors, including manufacturing, automotive, aerospace, and energy. In manufacturing, they are integral to hydraulic presses and machinery, ensuring smooth operation and reducing downtime. In automotive and aerospace industries, they protect sensitive components and systems from contaminants, thereby enhancing performance and safety. In the energy sector, Stauff Filters ensure the efficient operation of turbines and other equipment.

In the construction industry, Stauff Filters are employed in heavy machinery like excavators and bulldozers, where hydraulic systems operate under extreme conditions. By filtering hydraulic fluids, these filters prevent wear on hydraulic components, thus ensuring the longevity of the machinery. In agricultural machinery, Stauff Filters help maintain optimal performance of tractors and harvesters by providing clean fuel and hydraulic fluids, which is critical for efficient operation in the field.

Moreover, in the marine sector, Stauff Filters are essential for maintaining the hydraulic systems of ships and offshore platforms, where exposure to saltwater and other harsh conditions can lead to rapid degradation of components. The use of Stauff Filters in these applications helps to ensure reliable operation, minimizing the risk of breakdowns and enhancing safety on board.

Benefits of Using Stauff Filters

- Enhanced System Reliability: By effectively removing contaminants, these filters help prevent breakdowns and extend the life of machinery. This reliability is crucial in industries where downtime can lead to significant financial losses.

- Cost Efficiency: Reducing the need for frequent maintenance and repairs translates to cost savings over time. The initial investment in high-quality Stauff Filters can lead to substantial long-term savings by minimizing equipment failures and maintenance costs.

- Versatility: Available in a variety of models, Stauff Filters can be customized to fit different system requirements. This adaptability allows them to be utilized in a wide range of applications, making them a preferred choice among engineers and maintenance professionals.

- Improved Performance: Stauff Filters contribute to the overall performance of hydraulic and lubrication systems. By ensuring that the fluids are free from contaminants, they help maintain optimal viscosity and flow rates, which are critical for system efficiency.

- Environmental Protection: By preventing contaminants from entering the environment, Stauff Filters also contribute to sustainability efforts. Cleaner operations lead to less environmental impact, aligning with the growing emphasis on eco-friendly practices across industries.

Comparing Stauff Filters with Other Brands

| Feature | Stauff Filter | Other Brands |

|---|---|---|

| Durability | High | Varies |

| Efficiency | 99.9% Filtration | 95-99% |

| Customization | Extensive Options | Limited |

| Maintenance Ease | User-friendly Design | Complex |

| Material Quality | Premium Synthetic Fibers | Standard Materials |

When comparing Stauff Filters to other brands, it's clear that Stauff's commitment to quality and innovation sets them apart. Their extensive range of products and customization options allow engineers to find the right filter for specific applications, which is crucial in industries where performance and reliability are paramount. Furthermore, Stauff's focus on using premium materials enhances the overall durability and efficiency of their filters, giving them an edge over many competitors.

Installation and Maintenance Guide

Proper installation and maintenance are key to maximizing the performance of Stauff Filters. Here is a step-by-step guide:

- Installation: Ensure that the filter is compatible with the system's specifications. Follow the manufacturer's instructions for installation, taking care to secure all connections properly. It is advisable to use the appropriate tools and to avoid over-tightening connections, which can damage the filter.

- Routine Checks: Regularly inspect the filter for signs of wear or damage. Replace the filter element as recommended by the manufacturer to maintain optimal performance. Keeping a maintenance log can help track replacement schedules and filter performance.

- System Monitoring: Monitor the system's performance to identify any signs of reduced efficiency, which may indicate the need for filter maintenance or replacement. Pay attention to changes in pressure readings or unusual noises in the hydraulic system.

- Cleaning: If applicable, clean the external parts of the filter regularly to prevent dirt accumulation, which can affect performance. However, avoid using harsh chemicals that might degrade the filter materials.

- Training Personnel: Ensure that all personnel involved in the maintenance of Stauff Filters are adequately trained and understand the importance of filtration in the system. Regular training sessions can help reinforce best practices and safety measures.

FAQs

Q: How often should Stauff Filters be replaced?

A: The replacement frequency depends on the system's usage and the environmental conditions. It's generally recommended to follow the manufacturer's guidelines, which typically suggest replacing the filter element every 6-12 months. In high-demand applications, more frequent checks and replacements may be necessary to maintain optimal performance.

Q: Can Stauff Filters be used in extreme temperatures?

A: Yes, Stauff Filters are designed to operate efficiently under a wide range of temperatures, making them suitable for various industrial environments. Their construction includes materials that can withstand both high and low temperatures, ensuring consistent performance even in challenging conditions.

Q: Are there any specific industries where Stauff Filters are not recommended?

A: Stauff Filters are versatile and can be used in nearly any industry that requires fluid filtration. However, for specialized applications, such as those involving highly corrosive substances or extreme pressures, it's advisable to consult with a Stauff representative to ensure the filter meets the specific requirements. Stauff offers specialized filters that are tailored for such demanding conditions, ensuring safety and efficiency.

Q: What is the expected lifespan of a Stauff Filter?

A: The lifespan of a Stauff Filter can vary based on several factors, including the type of fluid being filtered, the level of contamination present, and the operating conditions. Generally, with proper maintenance and timely replacements, Stauff Filters can last up to 12 months or longer in less demanding environments. Regular monitoring and adherence to maintenance guidelines will help maximize their longevity.

Q: Are Stauff Filters environmentally friendly?

A: Yes, Stauff Filters are designed with sustainability in mind. Their efficient filtration systems reduce waste and minimize the release of contaminants into the environment. Moreover, the materials used in manufacturing these filters are often recyclable, contributing to a more sustainable lifecycle.

In conclusion, Stauff Filters are a vital component in maintaining the efficiency and reliability of hydraulic and lubrication systems across industries. Their robust design, high filtration efficiency, and versatility make them a preferred choice for professionals looking to enhance system performance and reduce maintenance costs. As industries evolve and environmental considerations become increasingly important, the role of high-quality filtration systems like those offered by Stauff will continue to be paramount in promoting sustainable practices and operational excellence.

Emerging Technologies in Filtration

The filtration industry is undergoing significant transformations due to advancements in technology. Stauff is at the forefront of these innovations, continually improving filter design and functionality. One of the most notable trends is the incorporation of smart technology into filtration systems. Smart filters can monitor fluid quality in real-time, providing valuable data that can be used to optimize system performance and maintenance schedules.

These smart filters utilize sensors to detect contaminants and monitor flow rates and pressure differentials. By integrating with digital systems, they can alert operators when maintenance is required, reducing the risk of unexpected failures. This predictive maintenance approach not only enhances reliability but also contributes to cost savings by allowing for timely interventions.

Another emerging trend is the development of biodegradable filter elements. As environmental regulations become stricter, the demand for sustainable products is increasing. Stauff is exploring the use of biodegradable materials in filter elements, which can significantly reduce environmental impact without compromising filtration efficiency.

Nanotechnology is also making strides in the filtration sector. Filters engineered with nanofibers have shown enhanced filtration capabilities, capturing smaller particles that traditional filters might miss. This technology holds promise for applications requiring ultra-fine filtration, such as in pharmaceuticals and food processing.

Case Studies: Stauff Filters in Action

To illustrate the effectiveness of Stauff Filters, let’s look at a few case studies from various industries.

In the automotive sector, a major manufacturer faced challenges with hydraulic system failures due to contamination. After switching to Stauff Filters, they experienced a dramatic reduction in downtime and maintenance costs. The filters effectively captured metal shavings and other particulates, extending the life of hydraulic components and improving overall system performance.

In the energy sector, a renewable energy company utilized Stauff Filters in their wind turbine hydraulic systems. The harsh environmental conditions posed a significant risk for contamination. By implementing Stauff Filters, the company ensured the reliability of their turbines, resulting in higher efficiency and reduced maintenance intervals. The filters' durability and high filtration efficiency contributed to a lower total cost of ownership for the turbines.

In the marine industry, a shipping company adopted Stauff Filters for their vessels' hydraulic systems. The filters played a crucial role in protecting critical components from seawater intrusion and other contaminants. The result was a marked improvement in operational reliability, which is essential for vessels operating in challenging marine environments where downtime can lead to substantial financial losses.

Conclusion

Stauff Filters stand out in the filtration market due to their commitment to quality, innovation, and reliability. With their extensive range of products, advanced technology integration, and focus on sustainability, Stauff is well-positioned to meet the evolving needs of various industries. As machinery and systems become more complex, the importance of effective filtration cannot be overstated. Investing in high-quality filtration solutions like Stauff Filters not only enhances system performance but also contributes to greater operational efficiency and environmental stewardship. By choosing Stauff, industries can ensure they are equipped with the best tools to face the challenges of modern operations, paving the way for a more sustainable and efficient future.