Understanding Stauff Filter Applications

Stauff Filters are essential components in hydraulic systems, ensuring the removal of contaminants and maintaining efficient operation. These filters are vital in various industrial applications, providing reliable performance and protection for hydraulic components. This guide delves into the functionality, benefits, and types of Stauff Filters used across diverse industries.

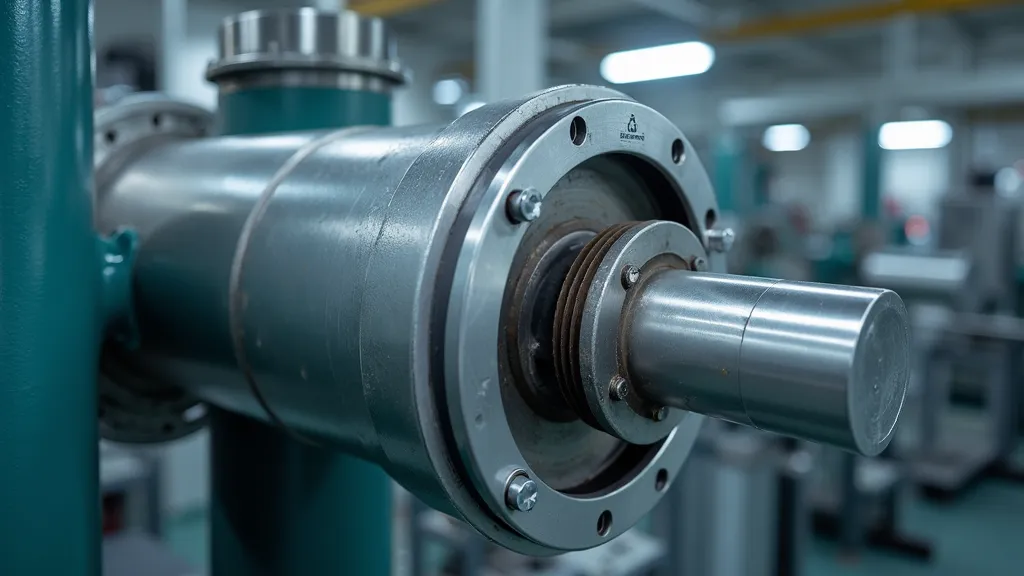

Introduction to Stauff Filters

Stauff Filters play a crucial role in maintaining the integrity and efficiency of hydraulic systems. These filters are engineered to remove contaminants, thereby extending the lifespan of hydraulic components and ensuring optimal system performance. Available in various configurations and sizes, Stauff Filters cater to a wide range of industrial applications, from construction machinery to manufacturing plants. The significance of these filters cannot be overstated, as they are essential for maintaining the overall health of hydraulic systems, which are integral to many industrial processes.

The Importance of Filtration in Hydraulic Systems

Hydraulic systems are the backbone of many industrial operations, providing power and control through pressurized fluid. However, these systems are susceptible to contamination by particles, water, and other impurities, which can lead to wear and tear, reduced efficiency, and costly downtime. Contaminants such as dirt, dust, and metallic particles can enter the hydraulic system during operation, or they can be generated internally through the wear of components. This contamination can significantly impact system performance and reliability. Implementing effective filtration solutions, such as Stauff Filters, is essential in minimizing these risks and maintaining system reliability. By ensuring clean hydraulic fluid, operators can avoid the expensive and disruptive consequences of equipment failure.

Types of Stauff Filters

Stauff offers a comprehensive range of filters designed to meet the specific needs of various hydraulic applications. The primary types include:

- Suction Filters: Installed in the hydraulic reservoir, these filters prevent large contaminants from entering the pump. They are designed to handle high flow rates and are typically used in conjunction with a strainer to provide maximum protection.

- Pressure Filters: Placed downstream of the pump, they protect sensitive components from fine particles and debris. These filters are critical for ensuring that the hydraulic fluid remains clean before it reaches the actuator, valves, and other vital components.

- Return Line Filters: Positioned in the return line to capture contaminants before the fluid re-enters the reservoir. This type of filter is essential for maintaining the purity of the fluid and preventing the recirculation of contaminants back into the system.

- Spin-On Filters: Easy to install and replace, these filters are ideal for applications requiring quick maintenance. They are commonly used in mobile equipment and can be replaced in a matter of minutes, allowing for minimal downtime.

Benefits of Using Stauff Filters

Stauff Filters offer several advantages that contribute to the overall health and performance of hydraulic systems:

- Enhanced System Reliability: By effectively removing contaminants, these filters reduce the risk of component failure and improve system uptime. This reliability is particularly important in industries where machinery operates under continuous or extreme conditions.

- Extended Component Life: Clean hydraulic fluid ensures less wear and tear on components, prolonging their operational life. This can lead to significant cost savings in terms of repairs and replacements, as well as reduced maintenance frequency.

- Energy Efficiency: Proper filtration leads to smoother operations and reduced energy consumption. When hydraulic systems operate efficiently, they require less power to perform the same tasks, which directly contributes to lower energy bills and a reduced carbon footprint.

- Cost Savings: Minimizing downtime and maintenance costs results in significant savings over time. The initial investment in quality filtration solutions, like Stauff Filters, pays off in the long run through enhanced productivity and operational efficiency.

Application Insights

Stauff Filters are versatile and find applications across various industries. In construction, they are vital in ensuring the reliability of heavy machinery, such as excavators and bulldozers, which operate in dusty and harsh environments. In manufacturing, they maintain the precision of equipment by keeping hydraulic systems clean, which is critical in processes that require high levels of accuracy, such as CNC machining and injection molding. Additionally, Stauff Filters are used in oil and gas, agriculture, and forestry, where machinery is exposed to harsh environments and requires robust filtration solutions.

In the oil and gas industry, for example, hydraulic systems are used in drilling and production equipment. The presence of contaminants can not only lead to equipment failure but also pose safety risks. Stauff Filters help mitigate these risks by providing reliable filtration solutions that ensure equipment operates safely and efficiently. Similarly, in agriculture, tractors and harvesters rely heavily on hydraulic systems to perform tasks such as lifting and steering. Using high-quality filters minimizes the risks of breakdowns during critical operations, thus enhancing productivity during peak seasons.

Expert Recommendations

Industry experts emphasize the importance of selecting the appropriate filter type and rating based on the specific requirements of the hydraulic system. The filtration needs can vary greatly depending on factors such as the type of fluid used, the operating environment, and the size and complexity of the hydraulic system. Regular maintenance and timely replacement of filters are also crucial to ensure continuous system protection. Stauff provides detailed guidelines and support to help users choose the right filtration solutions for their needs.

In addition to regular maintenance, experts recommend implementing a monitoring system that tracks the condition of the hydraulic fluid and filters. This proactive approach allows operators to anticipate potential issues before they escalate, thus avoiding unexpected downtime. Many companies have adopted predictive maintenance strategies, utilizing sensors and data analytics to monitor fluid quality and filter performance in real time. By leveraging technology, organizations can make informed decisions about when to replace filters and service equipment, further enhancing operational efficiency.

FAQs

- What is the primary function of a Stauff Filter?

Stauff Filters are designed to remove contaminants from hydraulic fluids, ensuring the protection and efficiency of hydraulic systems. This function is vital for preventing wear and tear on components and maintaining the overall performance of machinery. - How often should Stauff Filters be replaced?

The replacement frequency depends on the system's operating conditions and the manufacturer's recommendations, but regular checks are advised. Many operators establish a routine maintenance schedule that includes filter inspections and replacements based on operating hours or pressure drops across the filter. - Can Stauff Filters be used in extreme environments?

Yes, Stauff Filters are designed to withstand harsh conditions and are suitable for use in various challenging environments. They are built to resist corrosion, temperature fluctuations, and other adverse conditions, making them ideal for heavy-duty applications. - Where can I purchase Stauff Filters?

Stauff Filters are available through authorized distributors and online suppliers specializing in industrial filtration solutions. Customers can also access technical support and product information directly from Stauff’s website or their local representatives.

Conclusion

In conclusion, Stauff Filters are indispensable in preserving the functionality and longevity of hydraulic systems. By choosing the right filter type and maintaining a regular replacement schedule, industries can ensure the smooth operation of their machinery, leading to increased productivity and reduced operational costs. The importance of effective filtration cannot be overstated, as it directly correlates with system reliability and efficiency. As technology advances, Stauff continues to innovate, providing cutting-edge filtration solutions that meet the evolving demands of modern industries. Their commitment to quality and performance ensures that users can rely on Stauff Filters to protect their investments and enhance operational capabilities.

Future Trends in Hydraulic Filtration

As industries evolve and the demand for hydraulic systems increases, so too does the need for advanced filtration solutions. The future of hydraulic filtration is likely to be influenced by several key trends:

- Integration of Smart Technologies: With the rise of Industry 4.0, smart technologies are becoming increasingly prevalent in hydraulic systems. This includes sensors that monitor the condition of hydraulic fluids and filters in real time, providing valuable data that can be used to optimize filtration performance and predict maintenance needs.

- Focus on Sustainability: Environmental concerns are driving industries to adopt more sustainable practices. Future filtration solutions are expected to incorporate materials and processes that reduce environmental impact, such as recyclable filter elements and biodegradable fluids.

- Enhanced Filtration Efficiency: As hydraulic systems become more complex and operate under higher pressures, the demand for filters that can effectively capture smaller particles will rise. Innovations in filter media and design will lead to products that provide superior filtration without compromising flow rates.

- Customized Solutions: Different industries have unique filtration needs. The future will likely see a greater emphasis on customized filtration solutions that are tailored to specific applications, taking into account factors such as fluid type, operating conditions, and contamination sources.

The Role of Maintenance in Hydraulic Systems

Effective maintenance practices are critical for the longevity and reliability of hydraulic systems. Maintenance should encompass not only the replacement of filters but also the monitoring and management of hydraulic fluids. Fluid analysis can provide insights into the condition of the fluid and help identify potential issues before they lead to system failures. Regular checks for leaks, pressure drops, and unusual noises can also signal problems that need addressing. By establishing a comprehensive maintenance program, industries can maximize the lifespan of their hydraulic systems and minimize unplanned downtime.

Case Studies: Successful Implementation of Stauff Filters

Numerous organizations have successfully implemented Stauff Filters to enhance their hydraulic systems. For instance, a large construction company faced significant downtime due to hydraulic failures in their excavators. After switching to Stauff Filters, they reported a 30% reduction in maintenance costs and an increase in operational efficiency. This case exemplifies how the right filtration solutions can lead to substantial improvements in performance and reliability.

In the manufacturing sector, a leading automotive parts manufacturer faced challenges with contamination in their hydraulic systems, which affected precision machining processes. By incorporating Stauff Pressure Filters, they were able to maintain cleaner hydraulic fluid, thus improving product quality and reducing waste. This success story highlights the importance of investing in high-quality filtration solutions to enhance product reliability and operational efficiency.

Conclusion: The Path Forward

As industries continue to advance and evolve, the role of Stauff Filters in hydraulic systems will remain pivotal. The ongoing development of innovative filtration technologies will ensure that hydraulic systems can meet the demands of modern applications while maintaining efficiency and reliability. By prioritizing filtration as a critical component of hydraulic system design and maintenance, industries can safeguard their operations against the risks associated with contamination, thereby enhancing productivity and reducing costs. As we look to the future, the commitment to quality and performance from manufacturers like Stauff will play a crucial role in shaping the landscape of hydraulic filtration solutions.