Understanding the Stauff Filter System

The Stauff Filter is an essential component in hydraulic and lubrication systems, designed to maintain fluid cleanliness and system efficiency. This article delves into the technical aspects, applications, and benefits of using Stauff Filters, providing industry insights for professionals seeking to enhance machinery performance and longevity.

Introduction to Stauff Filters

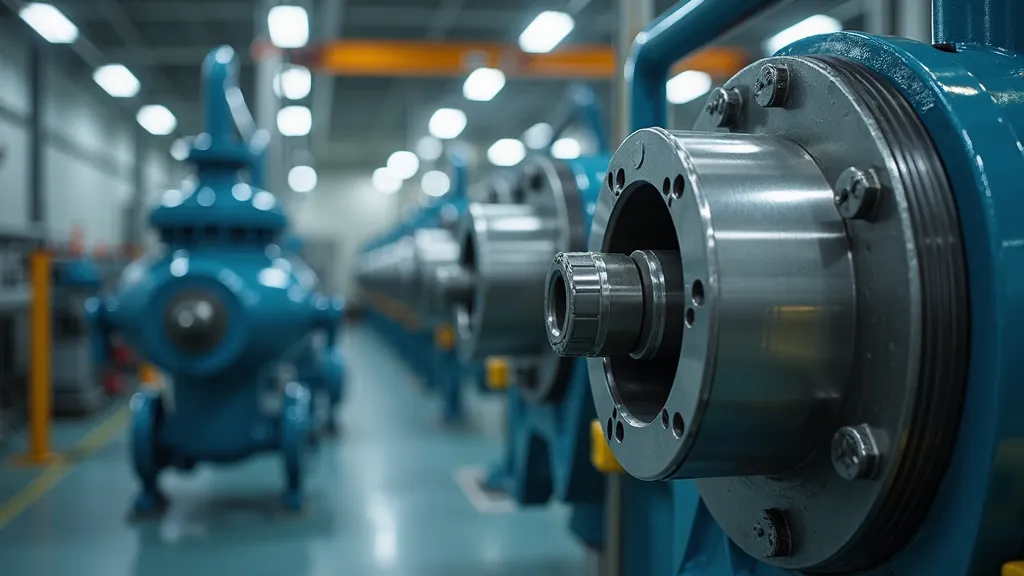

In the realm of industrial machinery and hydraulic systems, maintaining fluid cleanliness is paramount for ensuring the efficiency and longevity of equipment. The Stauff Filter stands out as a critical component in this regard, offering comprehensive solutions to filter contaminants from hydraulic and lubrication systems. Designed with precision, these filters are integral to systems that demand high performance and reliability. Their widespread use across various industries underscores their importance in maintaining operational excellence. The evolution of Stauff Filters reflects advancements in filtration technology, showcasing a commitment to innovation that addresses the ever-changing demands of modern industries.

The Role of Stauff Filters in Hydraulic Systems

Hydraulic systems are the backbone of numerous industrial applications, from manufacturing to heavy machinery. The Stauff Filter plays a vital role in these systems by removing impurities that can lead to wear and tear, system failures, and costly downtime. By ensuring the purity of hydraulic fluids, Stauff Filters enhance the overall efficiency and reliability of the machinery. The filters are engineered to trap particles, water, and other contaminants, thereby protecting sensitive components such as pumps, valves, and actuators. The importance of fluid cleanliness cannot be overstated; even small amounts of contamination can lead to catastrophic failures, increased operating costs, and reduced performance.

Technical Specifications and Features

Stauff Filters are renowned for their advanced engineering and robust construction. They are available in a variety of configurations to suit different system requirements. Key features include high dirt-holding capacity, low-pressure drop, and compatibility with a wide range of fluids. These filters are constructed from durable materials that withstand harsh operational environments, making them ideal for heavy-duty applications.

In addition to their standard specifications, Stauff Filters are often equipped with advanced features such as integrated bypass valves, which prevent excessive pressure buildup and allow for continuous operation even when the filter reaches its capacity. Some models include visual indicators that signal when a filter element needs changing, further simplifying maintenance tasks. The design considerations taken into account during the manufacturing process ensure that Stauff Filters can handle extreme conditions, including high temperatures and aggressive fluids, making them suitable for a diverse array of applications.

Applications Across Industries

Stauff Filters are utilized in diverse industries, including automotive, aerospace, oil and gas, and manufacturing. In each of these sectors, the filters contribute to enhanced equipment performance by maintaining fluid cleanliness. For instance, in the automotive industry, Stauff Filters ensure the precision operation of hydraulic systems in vehicles. This includes critical systems such as power steering and braking, where any contamination can lead to safety hazards and decreased performance. In the oil and gas sector, they are critical in maintaining the integrity of drilling and extraction equipment, where high levels of contamination can jeopardize operations and lead to costly spills and environmental damage.

Moreover, in the aerospace industry, where the stakes are particularly high, Stauff Filters are integral to hydraulic systems that control landing gear and flight control surfaces. The reliability of these systems is vital for the safety of passengers and crew, making the role of filtration even more critical. In manufacturing, Stauff Filters are deployed in hydraulic presses and CNC machines, where fluid cleanliness directly correlates with product quality and equipment lifespan. The versatility of Stauff Filters allows them to serve as a common solution across these varied applications, showcasing their fundamental role in modern industrial practices.

Benefits of Using Stauff Filters

The adoption of Stauff Filters in industrial systems brings numerous benefits. These include extended equipment life, reduced maintenance costs, and improved system efficiency. By preventing contamination-related issues, Stauff Filters help organizations minimize downtime and maximize productivity. Furthermore, they contribute to environmental sustainability by reducing the need for frequent fluid changes and disposal.

Extended equipment life is one of the most significant benefits of using Stauff Filters. By effectively capturing contaminants before they can damage critical components, these filters reduce wear and tear, resulting in longer operating cycles and less frequent need for replacements. This directly translates into cost savings for organizations, as they can avoid the financial burden associated with premature equipment failure and the associated downtime.

Another advantage is the reduced maintenance costs that come with the use of high-quality filtration systems. Regular maintenance schedules can be streamlined due to the filters' high dirt-holding capacity, allowing for longer intervals between changes. This not only minimizes labor costs but also allows maintenance teams to focus on other critical tasks, enhancing overall operational efficiency.

Additionally, Stauff Filters play a crucial role in promoting environmental sustainability. By ensuring that hydraulic fluids remain clean and usable for longer periods, organizations can contribute to less waste generation. This is an essential consideration in today's eco-conscious business landscape, where sustainability initiatives are increasingly prioritized.

Understanding Filter Maintenance and Replacement

To optimize the performance of Stauff Filters, regular maintenance and timely replacement are crucial. This involves monitoring the filter's pressure drop and inspecting for signs of wear or clogging. Replacing filters at recommended intervals ensures continuous protection of the hydraulic system. Stauff provides comprehensive guidelines and support to assist users in maintaining their filters effectively.

One of the key aspects of filter maintenance is understanding the pressure differential across the filter. As a filter collects contaminants, the pressure on the inlet side rises, while the pressure on the outlet side drops. Monitoring this pressure drop can provide valuable insights into the filter’s condition and when it may need replacement. Many Stauff Filters come equipped with pressure gauges or electronic monitoring systems that can alert operators when a filter is becoming clogged, reducing the risk of unexpected failures.

Furthermore, regular visual inspections of the filter housing and surrounding components can help identify issues before they escalate. Signs of leakage, unusual noises, or irregular vibrations can indicate underlying problems that may require immediate attention. By adhering to a proactive maintenance schedule and utilizing the resources provided by Stauff, operators can ensure that their filtration systems remain effective and reliable.

Comparison Table: Stauff Filters vs. Other Brands

| Feature | Stauff Filters | Other Brands |

|---|---|---|

| Dirt-Holding Capacity | High | Varies |

| Pressure Drop | Low | Varies |

| Material Durability | Robust | Varies |

| Compatibility | Wide Range of Fluids | Varies |

| Maintenance Ease | User-Friendly | Varies |

| Price Point | Competitive | Varies |

FAQs

- What is the primary function of a Stauff Filter? The primary function is to remove contaminants from hydraulic and lubrication systems to ensure efficient operation.

- How often should Stauff Filters be replaced? Replacement frequency depends on system usage and environment, but regular monitoring and maintenance are recommended.

- Are Stauff Filters compatible with all hydraulic systems? They are designed to be compatible with a wide range of systems and fluids, but it is advisable to consult with Stauff for specific applications.

- What types of contaminants can Stauff Filters remove? Stauff Filters are capable of removing solid particles, water, and other contaminants that may affect fluid quality and system performance.

- Can Stauff Filters be used in high-pressure applications? Yes, Stauff Filters are designed to handle high-pressure environments, making them suitable for various industrial applications.

- What are the signs of a clogged filter? Common indicators include increased pressure drop, unusual noises from the hydraulic system, and reduced performance of the machinery.

Conclusion

Stauff Filters are indispensable in maintaining the efficiency and reliability of hydraulic systems across various industries. Their superior design and performance make them a preferred choice for professionals aiming to enhance machinery longevity and reduce operational costs. By investing in high-quality filtration solutions like Stauff Filters, industries can safeguard their equipment, optimize performance, and achieve sustainable operational success.

In summary, the importance of filtration in hydraulic systems cannot be overstated. As industries continue to evolve and demand higher performance standards, the role of Stauff Filters will only become more critical. Companies that prioritize the use of advanced filtration solutions will not only ensure the longevity of their equipment but also position themselves as leaders in their respective fields. With a commitment to quality and innovation, Stauff Filters represent a key investment in the future of industrial operations, paving the way for enhanced productivity, safety, and environmental responsibility.