Comprehensive Guide to Stauff Filters

Stauff Filters are integral components for fluid filtration in industrial applications, known for their reliability and efficiency. This guide explores their functionalities, applications, and benefits, providing an expert analysis of their impact in maintaining system cleanliness and longevity, with insights into their operational mechanisms and importance in industry settings.

Understanding the Importance of Stauff Filters

In the ever-evolving industrial sector, maintaining the integrity and efficiency of machinery is paramount. Stauff Filters are critical components that ensure the longevity and optimal performance of hydraulic and lubrication systems by effectively removing contaminants from fluids. Their role in safeguarding equipment from potential damage caused by impurities is invaluable, making them a staple in industrial maintenance practices. As industries strive to optimize their operations and reduce costs, the significance of high-quality filtration systems like Stauff Filters cannot be overstated.

The impact of contaminants in hydraulic and lubrication fluids can lead to severe operational issues, including decreased efficiency, increased wear and tear, and ultimately, costly breakdowns. A single piece of debris can result in catastrophic failures, highlighting the necessity of effective filtration solutions. Thus, Stauff Filters provide not only a protective measure but also a strategic advantage in maintaining the operational efficacy of various systems.

Functionality and Design of Stauff Filters

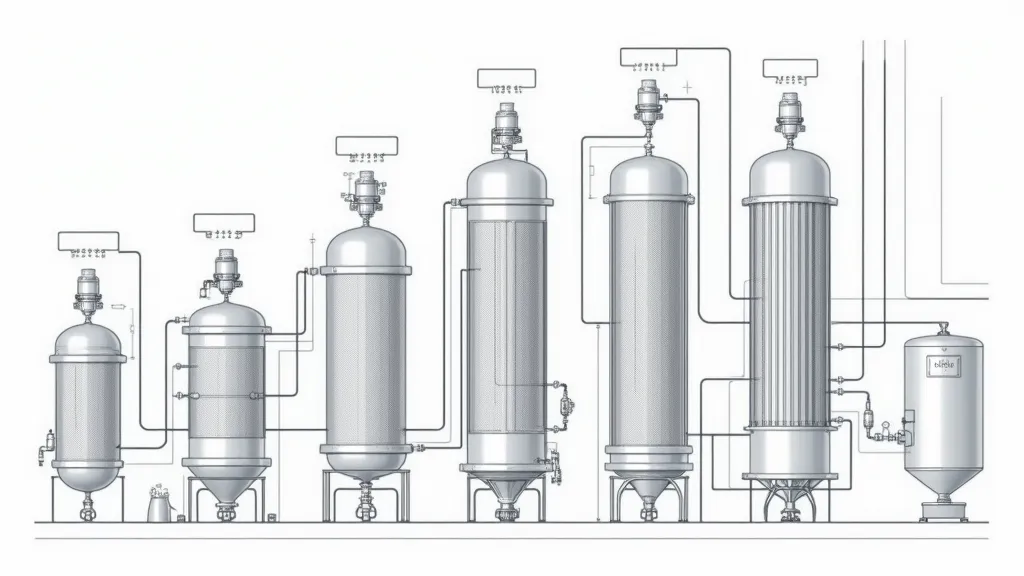

Stauff Filters are engineered to deliver high filtration efficiency with minimal pressure drop. The design typically includes a sturdy housing made from robust materials, capable of withstanding high pressures and temperatures. Inside, the filter element, often made from synthetic fiber or stainless steel mesh, traps particles and contaminants with precision. The filtration process is optimized to maintain fluid cleanliness without compromising the flow rate.

The technology behind Stauff Filters involves a combination of depth and surface filtration, allowing for a wide range of particle sizes to be captured effectively. Depth filtration works by trapping particles within the thickness of the filter media, while surface filtration captures larger particles on the surface. This dual mechanism enhances the filter's lifespan and performance, making it suitable for various applications.

Moreover, Stauff Filters incorporate innovative design features such as anti-drain valves, which prevent backflow and ensure that the filter remains saturated with fluid even when the system is temporarily shut down. This feature helps maintain a consistent flow of clean fluid, significantly contributing to the efficiency of hydraulic systems.

Applications of Stauff Filters

These filters are utilized across various industries, including manufacturing, automotive, and oil and gas. In hydraulic systems, they prevent wear and tear of components by filtering out particles that could cause abrasion and corrosion. In lubrication systems, they keep the lubricants clean, ensuring smooth operation of machinery and reducing the need for frequent oil changes.

In manufacturing, where hydraulic machinery is prevalent, the use of Stauff Filters is essential for maintaining the precision and reliability of operations. For instance, in a factory setting with hydraulic presses, any contamination can lead to defects in the products being manufactured. The same principle applies in automotive applications, where hydraulic systems control everything from braking to steering. A failure in these systems due to contamination can lead to unsafe conditions and costly recalls.

In the oil and gas sector, Stauff Filters play a critical role in safeguarding equipment used in drilling and extraction processes. The harsh environments and high pressures encountered in these applications necessitate reliable filtration systems that can operate under extreme conditions. Stauff Filters are designed to meet these demands, ensuring that the machinery operates efficiently and safely, mitigating the risks associated with fluid contamination.

Benefits of Using Stauff Filters

The primary advantage of Stauff Filters is their ability to extend the service life of equipment by preventing contaminants from accumulating in the system. This results in lower maintenance costs and reduced downtime. Additionally, by maintaining fluid cleanliness, these filters help in improving the overall efficiency of the machinery, leading to enhanced productivity and energy savings.

Another significant benefit is the reduction in environmental impact. By extending the life of fluids and machinery, Stauff Filters contribute to less waste and lower consumption of resources. In an era where sustainability is increasingly important, utilizing effective filtration systems aligns with corporate responsibility goals while also providing economic benefits.

Furthermore, the reliability of Stauff Filters translates to peace of mind for operators and maintenance teams. Knowing that they are equipped with high-quality filtration solutions allows companies to focus on their core operations without the constant worry of equipment failure due to contamination.

Comparison of Stauff Filters with Other Filter Brands

| Filter Brand | Key Features | Market Performance |

|---|---|---|

| Stauff | High efficiency, robust design, versatile applications | Widely trusted across industries for reliability |

| Brand X | Moderate efficiency, limited applications | Less preferred due to lower durability |

| Brand Y | Cost-effective, basic filtration capabilities | Popular in low-budget settings but less effective in high-demand scenarios |

When comparing Stauff Filters to other brands, several key factors come into play. Stauff Filters stand out due to their high efficiency and robust construction, which are vital for demanding industrial applications. While Brand X may offer moderate efficiency, it lacks the durability and versatility required for more rigorous environments. On the other hand, Brand Y, while cost-effective, may not provide the necessary performance in high-demand situations, leading to potential failures and increased long-term costs.

Installation and Maintenance of Stauff Filters

Installing a Stauff Filter requires attention to detail to ensure it operates effectively. Proper alignment and securing of the filter within the system are crucial. Regular maintenance involves inspecting the filter element for clogs and replacing it when necessary to maintain optimal filtration performance. Stauff provides detailed manuals and support to assist users in these processes.

During installation, it is important to follow the manufacturer’s guidelines, which include checking for correct orientation and ensuring that seals are properly seated to prevent leaks. Additionally, regular monitoring of the system's pressure gauge can provide valuable insights into the filter's performance; an increase in pressure differential may indicate that the filter is becoming clogged and requires replacement.

Maintenance schedules can vary depending on the application and the degree of contamination in the fluid. For instance, systems operating in environments with high levels of dust or debris may require more frequent filter changes compared to those in cleaner settings. Stauff offers a variety of filter elements tailored to different applications, allowing users to select the best option based on their specific needs and operating conditions.

FAQs

- What types of contaminants can Stauff Filters remove? Stauff Filters can effectively remove particles such as dirt, metal shavings, and other debris from hydraulic and lubrication fluids.

- How often should the filter elements be replaced? The frequency of replacement depends on the operating conditions and fluid cleanliness requirements. Regular inspections can help determine the optimal replacement schedule.

- Are Stauff Filters compatible with all hydraulic systems? While Stauff Filters are designed to be versatile, it is advisable to consult the manufacturer's specifications to ensure compatibility with specific systems.

- Can Stauff Filters improve energy efficiency? Yes, by maintaining clean hydraulic and lubrication fluids, Stauff Filters help improve the overall efficiency of machinery, leading to reduced energy consumption.

- What is the expected lifespan of a Stauff Filter? The lifespan of a Stauff Filter can vary based on usage and environmental conditions, but proper maintenance can significantly extend its life.

Conclusion

Stauff Filters play a pivotal role in ensuring the smooth and efficient operation of industrial machinery. Their ability to maintain fluid cleanliness translates to enhanced equipment performance and longevity, making them an essential component in the industrial maintenance toolkit. By choosing Stauff Filters, industries can achieve greater reliability, reduced maintenance costs, and improved productivity.

As industries continue to innovate and evolve, the demand for high-quality filtration solutions will only increase. Stauff Filters, with their advanced technology and reliable performance, represent a critical investment in the future of industrial operations. By prioritizing filtration as a key component of maintenance strategies, businesses can not only safeguard their equipment but also enhance their overall operational efficiency and competitiveness in the marketplace.

In conclusion, the importance of Stauff Filters cannot be underestimated in today's fast-paced industrial landscape. As organizations strive for optimal performance and sustainability, incorporating effective filtration systems will be essential for achieving long-term success and resilience against the challenges ahead.

Moreover, as we look to the future, advancements in filtration technology and materials are likely to further enhance the capabilities of Stauff Filters. Continuous research and development will enable the creation of even more efficient filtration solutions, addressing the ever-growing needs of various industries. This commitment to innovation will ensure that Stauff remains at the forefront of filtration technology, helping industries navigate the complexities of modern manufacturing and maintenance practices.