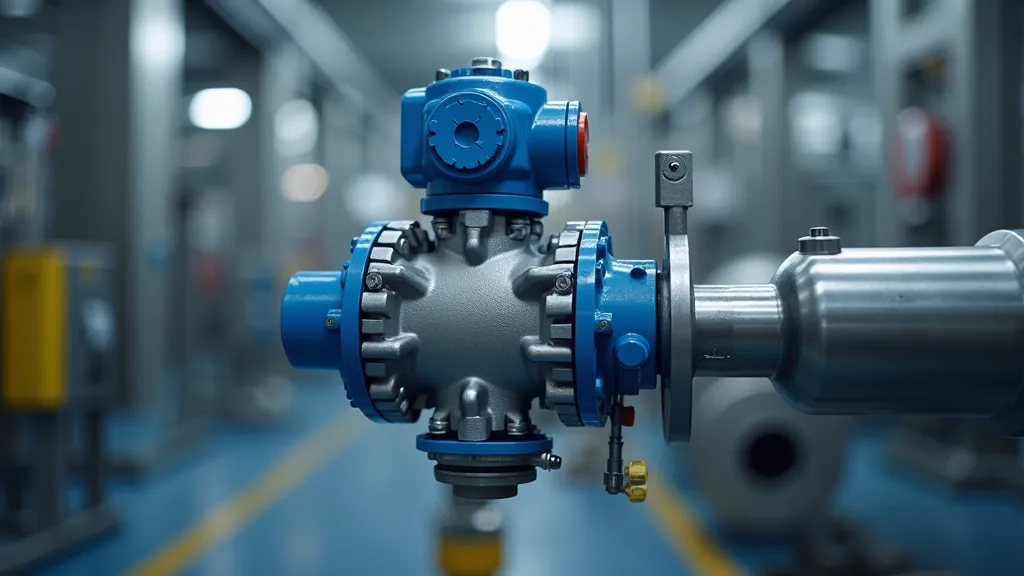

Understanding Rexroth Poppet Valves

Rexroth poppet valves are crucial components in hydraulic systems, offering precise control of fluid flow and pressure. Known for their reliability and efficiency, these valves are widely used in various industrial applications. This article delves into their functionality, advantages, and common applications, providing a detailed overview for industry professionals and enthusiasts alike.

Introduction to Rexroth Poppet Valves

Rexroth poppet valves are integral components in hydraulic systems, known for their ability to regulate the flow and pressure of fluids with high precision. These valves are essential in various industrial applications, including manufacturing, automotive, and aerospace sectors. Their design ensures reliable performance, making them a preferred choice for engineers and technicians. The importance of hydraulic systems in modern machinery cannot be overstated; they provide the necessary force and control for a myriad of applications. Understanding the role of Rexroth poppet valves within these systems is vital for anyone involved in engineering, maintenance, or operation of hydraulic equipment.

How Rexroth Poppet Valves Work

At the core of a Rexroth poppet valve is a disc or cone that seals against a seat to control the flow of fluid. When pressure is applied, the poppet moves, allowing fluid to pass through. This mechanism provides a quick response and ensures minimal leakage, which is crucial for maintaining system integrity and efficiency. The operation of these valves can be understood through their basic components, which include the valve body, the poppet itself, and the seat against which the poppet seals. When the valve is closed, the poppet is seated tightly against the seat, preventing any fluid flow. When the hydraulic pressure exceeds the force exerted by the spring or the weight of the poppet, the valve opens, allowing fluid to flow through the designated pathway.

Rexroth poppet valves can be operated in various ways, including manually, electrically, or hydraulically. The choice of actuation method can influence the valve's responsiveness and suitability for specific applications. For instance, electrically actuated poppet valves can provide precise control and quick response times, making them ideal for applications requiring rapid cycling or dynamic adjustment of flow. Conversely, manually operated valves may be preferable in situations where automatic control is not necessary, or where operator intervention is required for safety or operational reasons.

Advantages of Using Rexroth Poppet Valves

- Reliability: Due to their robust construction, these valves can withstand high pressure and harsh environments. The materials used in their manufacture are selected for their strength and resistance to wear, ensuring long-lasting performance even in demanding applications.

- Precision: They offer accurate flow control, essential for applications requiring precise fluid handling. This precision is critical in sectors like aerospace and automotive, where even minor deviations in fluid flow can lead to significant operational issues.

- Durability: With minimal moving parts, Rexroth poppet valves require less maintenance and have a longer service life. This durability translates to lower overall operational costs, as frequent replacements or repairs are less likely to be needed.

- Versatility: These valves are designed to be used in a variety of configurations and can be adapted for use in different types of hydraulic circuits. This adaptability makes them suitable for a wide range of applications, from simple systems to complex industrial machinery.

- Low Leakage: One of the standout features of Rexroth poppet valves is their ability to minimize leakage when closed. This characteristic is particularly important in applications where fluid loss can lead to inefficiencies or safety hazards.

Common Applications

Rexroth poppet valves are found in a variety of settings, including:

- Manufacturing: Used in automated machinery for precise control of hydraulic systems. In manufacturing settings, these valves help maintain consistent performance levels, crucial for processes such as metal forming, plastic injection molding, and assembly line operations.

- Automotive: Integral in braking systems and other fluid control applications. In the automotive industry, poppet valves are often used in anti-lock braking systems (ABS), where their ability to respond quickly to changing pressures is essential for maintaining vehicle control and safety.

- Aerospace: Applied in systems where reliability and precision are paramount. The aerospace sector relies heavily on hydraulic systems for flight control surfaces, landing gear operation, and various actuation mechanisms. Here, the high-performance standards demanded by regulatory bodies necessitate the use of reliable components like Rexroth poppet valves.

- Construction Equipment: In heavy machinery, these valves facilitate the operation of hydraulic cylinders and motors, allowing for the controlled movement of equipment such as excavators, bulldozers, and cranes. The ability to handle high pressures and provide precise control is critical in these applications, where safety and efficiency are paramount.

- Marine Applications: Rexroth poppet valves are also used in various marine applications, including hydraulic steering systems and winches. The marine environment presents unique challenges such as exposure to saltwater and varying temperatures, making the durability and reliability of these valves even more critical.

Expert Perspective on Industry Trends

According to industry experts, the demand for reliable and efficient hydraulic components like Rexroth poppet valves is on the rise. As industries move towards automation and increased precision, the need for valves that can offer exact flow control without compromising on durability becomes essential. The trend towards smarter manufacturing and Industry 4.0 is driving innovation in hydraulic technologies, with a focus on integrating sensors and smart controls into hydraulic systems. This evolution requires components that not only perform well mechanically but can also communicate data regarding their status and performance.

Moreover, as sustainability becomes a significant focus across industries, manufacturers are seeking hydraulic solutions that minimize energy consumption and reduce environmental impact. Rexroth poppet valves, with their low leakage rates and high efficiency, are well-positioned to meet these demands. The integration of advanced materials and coatings can further enhance their performance, making them suitable for a broader range of applications while aligning with sustainability goals.

Additionally, the globalization of manufacturing and increased competition are pushing companies to seek out components that provide a competitive edge. Rexroth poppet valves, known for their reliability and performance, are consistently chosen as a standard in new machinery design, ensuring that manufacturers remain at the forefront of technology and efficiency.

FAQs

- What makes Rexroth poppet valves unique?

Rexroth valves are renowned for their precision and reliability, thanks to their robust design and high-quality materials. The combination of advanced engineering and rigorous testing ensures that these valves perform consistently in demanding environments. - Are these valves suitable for high-pressure applications?

Yes, Rexroth poppet valves are designed to handle high-pressure scenarios efficiently. Their construction is geared towards withstanding the stresses associated with high-pressure hydraulic systems, making them an ideal choice for such applications. - How often should these valves be maintained?

Regular inspections are recommended, but due to their durable design, they require less frequent maintenance compared to other valves. A proactive maintenance schedule, including periodic checks for wear and tear, can help ensure optimal performance and longevity. - Can Rexroth poppet valves be customized?

Yes, many manufacturers offer customization options for Rexroth poppet valves to meet specific application requirements. This may include alterations in valve size, pressure ratings, or even the materials used in construction. - What are the typical failure modes for poppet valves?

Common failure modes for poppet valves include seat wear, which can lead to leakage, and spring fatigue, which can affect the valve's responsiveness. Regular maintenance and monitoring can help mitigate these issues before they lead to significant operational problems.

Conclusion

Rexroth poppet valves are indispensable in modern hydraulic systems, offering unmatched precision and reliability. Their application across various industries highlights their versatility and importance in achieving efficient fluid control. For those in the field, understanding these components is crucial for optimizing system performance and ensuring good operational success. As technology continues to evolve, so too will the designs and capabilities of hydraulic components like Rexroth poppet valves, ensuring they remain at the forefront of industrial innovation.

In summary, whether in manufacturing, automotive, aerospace, or any multitude of other fields, Rexroth poppet valves provide a vital connection between hydraulic systems and their operational success. Their ability to maintain precise flow control, withstand extreme conditions, and operate efficiently makes them a top choice for engineers and industry professionals alike. As industries continue to push the boundaries of what is possible, the role of such components will only grow in significance, paving the way for advancements that will define the next generation of hydraulic technology.

For engineers and technicians, staying updated on the latest developments in poppet valve technology and understanding their applications will be essential in driving innovation and efficiency in hydraulic systems. By leveraging the benefits of Rexroth poppet valves, professionals can contribute to the creation of safer, more reliable, and efficient machinery and equipment, ultimately enhancing productivity and performance across various sectors.