Comprehensive Guide to Rexroth Poppet Valve

This article delves into the intricacies of the Rexroth poppet valve, a crucial component in hydraulic systems known for its reliability and efficiency. The guide explores its applications, operational principles, and benefits, offering insights from industry experts for an in-depth understanding. Explore the mechanics behind its design and how it contributes to optimized industrial operations.

Understanding the Rexroth Poppet Valve

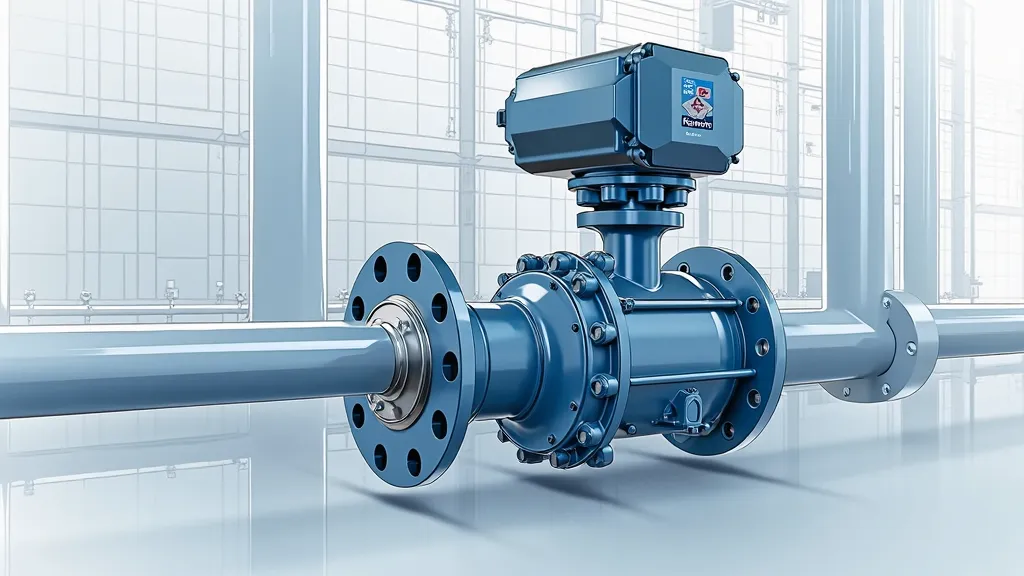

The Rexroth poppet valve is a pivotal element in hydraulic systems, renowned for its reliability and efficiency. Designed by Bosch Rexroth, a leader in drive and control technologies, this valve is engineered to regulate fluid flow in industrial applications seamlessly. Its robust design and precise control make it indispensable in sectors requiring high performance and durability. These valves contribute significantly to the overall efficiency of hydraulic systems, helping to optimize energy consumption and reduce operational costs.

Core Functionality and Design

Poppet valves, including those produced by Rexroth, operate on a simple yet effective principle: controlling fluid flow through a movable disk or ball that sits on a seat. When actuated, this element lifts, allowing fluid to pass through. The Rexroth poppet valve's design emphasizes minimal leakage and rapid response times, crucial for maintaining the efficiency of hydraulic systems. Notably, the valve's components, such as the seat and sealing elements, are meticulously crafted to withstand harsh operating conditions, ensuring long-term reliability.

Moreover, the construction of Rexroth poppet valves involves advanced materials that enhance their durability. For instance, the use of high-strength alloys and polymers can significantly extend the lifespan of the valve, even in extreme environments. With precision engineering, these valves can accommodate various flow rates and pressures, making them adaptable to a wide range of applications.

Applications Across Industries

Rexroth poppet valves are versatile and can be found across various industries, including manufacturing, automotive, and aerospace. Their ability to handle high pressure and flow rates with precision makes them ideal for applications such as injection molding machines, metal forming presses, and even in the automation of complex manufacturing processes. In the automotive sector, these valves are crucial in hydraulic systems that power steering, braking, and suspension, where reliability and responsiveness are paramount.

In aerospace applications, the need for lightweight yet robust components is critical. Rexroth poppet valves meet these requirements by providing high performance with reduced weight, which is essential for aircraft design and fuel efficiency. Additionally, in the energy sector, these valves play a vital role in hydraulic systems used in renewable energy applications, such as wind turbines and hydroelectric power plants, where precise control over fluid dynamics is necessary for optimal operation.

Comparative Analysis: Rexroth vs. Competitors

| Feature | Rexroth Poppet Valve | Competitor A | Competitor B |

|---|---|---|---|

| Response Time | High | Moderate | High |

| Pressure Handling | Up to 350 bar | Up to 300 bar | Up to 400 bar |

| Leakage Rate | Minimal | Moderate | Minimal |

| Weight | Lightweight Design | Standard | Heavy Duty |

| Price Point | Premium | Economical | Moderate |

Expert Insights on Performance and Maintenance

Industry experts emphasize the importance of regular maintenance to ensure the longevity and optimal performance of Rexroth poppet valves. Routine inspections, cleaning, and timely replacement of worn-out parts are recommended to prevent unexpected downtimes. Regular maintenance can also help in identifying potential issues before they escalate into costly repairs. Rexroth's global network of service centers provides comprehensive support, ensuring that any issues are addressed promptly. These centers are equipped with the latest diagnostic tools and staffed by trained technicians who understand the intricacies of hydraulic systems.

Furthermore, experts suggest implementing a maintenance schedule that includes not only visual inspections but also functional testing of the valves. This could involve monitoring the response time and checking for any signs of leakage. Keeping detailed records of maintenance activities can aid in tracking performance trends and identifying areas that may require attention.

Innovations and Future Trends

As industries evolve, so does the technology behind hydraulic valves. Rexroth continues to innovate, integrating smart technologies to enhance the capabilities of their poppet valves. This includes the incorporation of sensors for real-time monitoring and diagnostic capabilities, paving the way for predictive maintenance and increased automation in industrial processes. These advancements allow for the collection of data regarding valve performance, enabling operators to optimize fluid dynamics and improve system efficiency.

Looking ahead, the trend toward Industry 4.0 and the Internet of Things (IoT) will further transform the landscape of hydraulic systems. By utilizing big data analytics, manufacturers can gain insights into operational efficiency and predict when maintenance should be performed, minimizing unplanned downtime. Additionally, the development of eco-friendly hydraulic fluids and materials in valve construction aligns with the growing emphasis on sustainability in industrial operations.

FAQs

- What makes the Rexroth poppet valve unique?

The Rexroth poppet valve is distinct for its high-pressure handling, minimal leakage, and rapid response time, making it ideal for demanding industrial applications. Additionally, its lightweight design and high durability set it apart from many competitors.

- How often should maintenance be conducted on Rexroth poppet valves?

Regular maintenance is crucial and should be conducted at intervals recommended by Rexroth, usually every 6 to 12 months, depending on usage and operating conditions. For more demanding applications, more frequent checks may be warranted.

- Can Rexroth poppet valves be used in automotive applications?

Yes, due to their precision and reliability, Rexroth poppet valves are suitable for various automotive applications, including vehicle hydraulic systems such as brakes and steering, where precision is critical for safety and performance.

- Where can I purchase Rexroth poppet valves?

Rexroth poppet valves are available through authorized distributors and Rexroth's official sales channels to ensure authenticity and support. Customers can also access a wide range of resources and technical support through these channels.

Conclusion

The Rexroth poppet valve stands out as a critical component in modern hydraulic systems, offering unmatched reliability and performance. Its robust design and responsiveness make it a preferred choice across industries. As technology advances, Rexroth's commitment to innovation ensures that their poppet valves will continue to meet the evolving needs of industrial applications worldwide. The integration of smart technologies and a focus on sustainability will likely shape the future of hydraulic systems, ensuring that they remain efficient and capable of adapting to new challenges.

Additional Considerations for Selecting Poppet Valves

When selecting a poppet valve for specific applications, several factors should be considered beyond just the basic specifications. Understanding the operational environment is crucial; factors such as temperature, fluid type, and potential contaminants can influence the valve's performance and lifespan. For instance, in environments where there is a risk of corrosion, choosing a valve made from stainless steel or with protective coatings is advisable.

Another consideration is the valve's compatibility with existing hydraulic systems. Ensuring that the valve integrates seamlessly with current components can prevent issues related to flow dynamics and pressure drops. This might involve consulting with engineers or technical experts who can provide insight into the compatibility of different systems.

Technological Advancements and Smart Hydraulics

The integration of smart technologies into hydraulic systems is revolutionizing how industries operate. Rexroth is at the forefront of this movement, not only producing high-quality poppet valves but also developing systems that incorporate IoT capabilities. These systems allow for real-time monitoring and adjustments based on operational data, significantly improving efficiency and reducing waste.

For instance, smart sensors can be installed on Rexroth poppet valves to monitor parameters such as pressure, temperature, and flow rate. This data can be transmitted to central control systems where algorithms analyze the information to optimize performance. Such innovations not only enhance the reliability of hydraulic systems but also support predictive maintenance strategies, allowing operators to address potential issues before they lead to system failures.

Case Studies: Successful Implementations of Rexroth Poppet Valves

Several industries have successfully implemented Rexroth poppet valves, showcasing their versatility and reliability. In the automotive sector, a major manufacturer adopted Rexroth poppet valves in their assembly lines to improve the efficiency of their hydraulic presses. By upgrading to these valves, the manufacturer reported a significant reduction in cycle times and an increase in the precision of component assembly, leading to higher overall productivity.

In the manufacturing of renewable energy equipment, a wind turbine manufacturer utilized Rexroth poppet valves in their hydraulic control systems. The valves' ability to maintain consistent performance under varying load conditions was critical in ensuring the turbines operated efficiently. This application not only improved the reliability of the turbines but also contributed to the overall sustainability goals of the company.

Challenges in Hydraulic System Design

Despite the advantages of using poppet valves, designers and engineers face several challenges in hydraulic system design. One of the foremost challenges is ensuring that the entire system works harmoniously. The introduction of new components, such as Rexroth poppet valves, must be carefully integrated into existing systems to avoid issues such as cavitation or pressure imbalances.

Another challenge is the need for ongoing training and education for personnel working with hydraulic systems. As technology evolves, so do the skills required to maintain and operate these systems effectively. Manufacturers must invest in training programs to ensure that their teams are knowledgeable about the latest technologies and best practices.

Conclusion: The Future of Rexroth Poppet Valves

As industries continue to evolve, the demand for reliable and advanced hydraulic components like the Rexroth poppet valve will only grow. With a strong focus on innovation, efficiency, and sustainability, Rexroth is well-positioned to lead the way in hydraulic technology. The continued integration of smart technologies and the development of environmentally responsible products will ensure that Rexroth remains a key player in the hydraulic systems market for years to come. As businesses seek to enhance their operational efficiency and reduce their environmental footprint, the role of advanced hydraulic components like Rexroth poppet valves will be crucial.