Understanding Rexroth Valve Applications

This article explores the critical role of Rexroth Valves in industrial applications, highlighting their design, functionality, and advantages. Rexroth Valves are integral components in hydraulic systems, known for their precision and reliability, which are essential for efficient industrial operations. The article provides an expert analysis, addressing common questions about these valves and their usage.

Introduction to Rexroth Valves

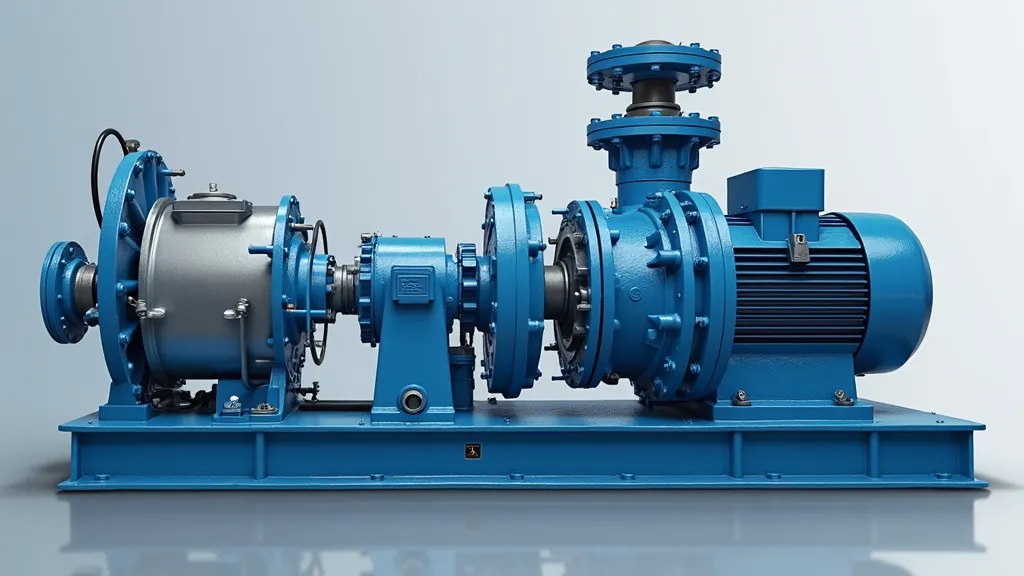

Rexroth Valves are pivotal components in various hydraulic systems, renowned for their precision and dependability. These valves are instrumental in regulating fluid flow, pressure, and direction, making them indispensable in industries ranging from manufacturing to construction. With a commitment to innovation and quality, Rexroth Valves ensure optimal performance and efficiency in complex industrial settings. Their development stems from decades of engineering expertise and a deep understanding of fluid dynamics, positioning them as leaders in hydraulic technology.

Key Features of Rexroth Valves

Rexroth Valves stand out due to their advanced design and engineering excellence. They offer a wide range of functionalities, including directional control, pressure control, and flow control, catering to diverse industrial needs. The precision machining and robust materials used in their construction guarantee durability and longevity, even in demanding environments. Additionally, Rexroth Valves are designed with user-friendliness in mind, featuring intuitive interfaces that simplify operation and maintenance.

One of the hallmark features of Rexroth Valves is their ability to function in extreme conditions, such as high temperatures, corrosive environments, and fluctuations in pressure. This resilience is particularly beneficial in sectors such as oil and gas, where valves must withstand rigorous operational demands. Furthermore, the valves incorporate smart technology that allows for remote monitoring and diagnostics, facilitating proactive maintenance and minimizing downtime.

Applications in Industry

These valves are extensively used in sectors such as automotive manufacturing, aerospace, and heavy machinery. They facilitate precise control over hydraulic systems, enhancing the performance and safety of equipment. For instance, in the automotive industry, Rexroth Valves contribute to the efficiency of assembly lines, allowing for synchronized operations that improve throughput and reduce cycle times. In aerospace, they play a crucial role in flight control systems, ensuring the precise movement of control surfaces and landing gear, which is vital for safety and performance.

In construction and heavy machinery, Rexroth Valves are essential for operating hydraulic excavators, bulldozers, and cranes. By managing the flow of hydraulic fluid, these valves allow for controlled movements and operations, thereby increasing productivity on job sites. The ability to accurately control hydraulic actuators translates to enhanced operational efficiency and reduced wear on equipment, ultimately leading to lower maintenance costs and extended equipment life.

| Type of Valve | Application | Benefits |

|---|---|---|

| Directional Control Valve | Controls the path of fluid within the system | Improves system responsiveness and accuracy |

| Pressure Control Valve | Regulates system pressure to prevent overloads | Enhances safety and prevents equipment damage |

| Flow Control Valve | Manages the flow rate of hydraulic fluid | Ensures consistent system performance |

| Proportional Valve | Provides variable control of flow and pressure | Enables precise control for applications requiring fine adjustments |

| Check Valve | Prevents backflow in hydraulic systems | Increases system reliability and efficiency |

Supplier Insights

When selecting a supplier for Rexroth Valves, it is essential to consider factors such as product authenticity, after-sales support, and the supplier’s industry reputation. Leading suppliers provide comprehensive support, including installation guidance and maintenance services, ensuring that the valves perform optimally throughout their lifecycle. It is advisable to engage with suppliers that have a proven track record in the industry, as this often correlates with the quality of service and support you will receive.

Moreover, many suppliers offer tailored solutions that can be customized to meet specific operational requirements. This customization can include adjustments to valve specifications, integration with existing systems, and the provision of additional components such as sensors and controllers. By collaborating closely with suppliers, companies can enhance the functionality of their hydraulic systems and ensure that they are well-equipped to handle evolving industry demands.

FAQs

- What are the primary benefits of using Rexroth Valves?

Rexroth Valves offer high precision, reliability, and durability, making them ideal for demanding industrial applications. They ensure efficient system performance and reduce the risk of downtime. Additionally, their ability to adapt to various operating conditions allows for greater flexibility in system design.

- How do Rexroth Valves improve system safety?

These valves incorporate advanced control features that regulate pressure and flow, minimizing the risk of system failures and enhancing overall safety. Features such as pressure relief and overload protection are critical in preventing catastrophic failures that could lead to equipment damage or safety hazards.

- Can Rexroth Valves be integrated into existing systems?

Yes, Rexroth Valves are designed to be compatible with various hydraulic systems, facilitating easy integration and upgrading of existing setups. This compatibility is essential for businesses looking to modernize their equipment without incurring significant costs associated with complete system overhauls.

- What maintenance is required for Rexroth Valves?

Regular maintenance for Rexroth Valves typically includes inspection for wear and tear, cleaning of components, and checking for leaks. Depending on the operating environment and usage, it may also involve replacing seals and other wear parts to ensure optimal performance.

- Are there specific industries where Rexroth Valves are most commonly used?

Rexroth Valves are commonly used in industries such as manufacturing, construction, automotive, aerospace, and agriculture. Each of these sectors benefits from the valves' precision control capabilities, which enhance productivity and operational efficiency.

Conclusion

Rexroth Valves are a cornerstone of efficient hydraulic systems, offering unmatched precision and reliability. Their versatile applications across multiple industries underscore their importance in driving operational success. By understanding their features and benefits, businesses can make informed decisions to enhance their hydraulic systems and maintain a competitive edge. As technology continues to evolve, so too do the capabilities of Rexroth Valves, incorporating advancements in automation and remote monitoring to meet the demands of the future.

Advancements in Rexroth Valve Technology

The evolution of Rexroth Valves has been marked by significant technological advancements that have enhanced their functionality and performance. Innovations such as electronic control systems have transformed traditional hydraulic systems into highly automated setups. These systems enable real-time monitoring and adjustments, allowing for greater precision and efficiency in operations.

Furthermore, the integration of IoT (Internet of Things) technology into Rexroth Valves is paving the way for smart hydraulic systems. By embedding sensors within the valves, operators can gather data on performance metrics, predict maintenance needs, and optimize system operations. This predictive maintenance approach not only reduces downtime but also extends the lifespan of hydraulic components, leading to substantial cost savings for businesses.

Choosing the Right Rexroth Valve

Selecting the appropriate Rexroth Valve for a specific application requires careful consideration of several factors. First and foremost, understanding the operational requirements—such as flow rate, pressure, and environmental conditions—is crucial. Each application may demand a unique combination of valve types and specifications to achieve optimal performance.

Additionally, it is important to consider the regulatory standards and certifications applicable to the industry in which the valves will be used. Rexroth Valves are designed to meet rigorous quality and safety standards, and ensuring compliance with these regulations is essential for operational integrity and safety. Consulting with engineering professionals or valve specialists can provide valuable insights into the best options for your specific needs.

Case Studies: Rexroth Valves in Action

To illustrate the impact of Rexroth Valves in real-world applications, consider the following case studies. In the automotive industry, a leading manufacturer implemented Rexroth Valves in their assembly line to enhance the precision of robotic arms. The result was a 20% increase in production efficiency, as the valves allowed for smoother and quicker movements of the robots, reducing cycle times and improving overall throughput.

In another instance, a construction company utilized Rexroth Valves in their hydraulic excavators, which faced challenges with inconsistent hydraulic flow that affected digging performance. By upgrading to Rexroth Valves, the operator achieved enhanced control over the hydraulic system, leading to more accurate and efficient digging operations. This upgrade not only improved productivity but also reduced fuel consumption, demonstrating the economic benefits of using high-quality hydraulic components.

Future Trends in Hydraulic Systems

The future of hydraulic systems, including Rexroth Valves, is poised to be shaped by several key trends. One of the most significant trends is the move towards electrification in hydraulic systems. Traditional hydraulic systems, which rely heavily on hydraulic fluid, are being integrated with electric drives to create hybrid systems that offer the benefits of both technologies. This shift not only improves energy efficiency but also allows for more precise control over hydraulic operations.

Moreover, sustainability is becoming a driving force in the design and operation of hydraulic systems. Manufacturers are increasingly focused on reducing the environmental impact of their products, leading to innovations in materials and processes. Rexroth, for example, is exploring the use of biodegradable hydraulic fluids and recyclable materials in their valve designs, contributing to a more sustainable approach in the industry.

Lastly, the rise of automation and artificial intelligence is set to redefine hydraulic system management. Advanced algorithms can analyze data from hydraulic systems to optimize performance and predict failures before they occur. This technological integration will revolutionize how businesses approach hydraulic operations, providing unprecedented efficiency and reliability.

Conclusion: Embracing the Future of Rexroth Valves

Rexroth Valves are not just components of hydraulic systems; they are integral to the advancement of technology in various industries. As businesses continue to seek improvements in efficiency, safety, and sustainability, Rexroth Valves will remain at the forefront of these efforts. By understanding the features, benefits, and future trends associated with these valves, companies can position themselves to harness the full potential of hydraulic systems and drive innovation in their respective fields.

In summary, Rexroth Valves exemplify the intersection of engineering excellence and technological innovation. Their reliability, precision, and adaptability make them essential for modern industrial applications. As industries continue to evolve, the role of Rexroth Valves will be crucial in facilitating progress and achieving operational excellence.