Understanding Rexroth Valve Systems

This article delves into the intricate world of Rexroth valves, exploring their significance in various industrial applications. Renowned for precision engineering and reliability, these valves play a crucial role in controlling fluid dynamics in machinery. This guide provides a comprehensive analysis of their functionality, market presence, and technological advancements, offering insights from industry experts.

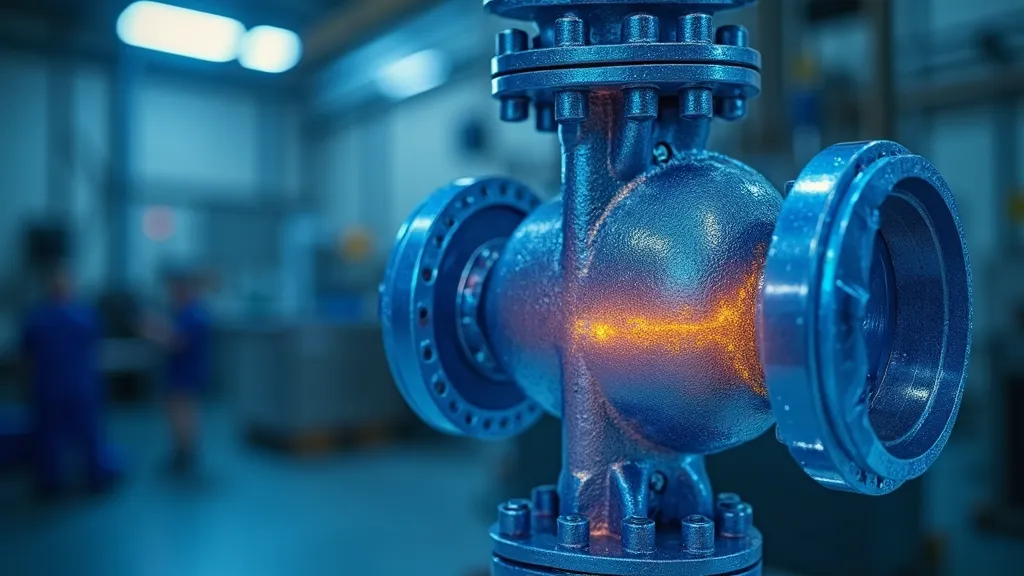

Introduction to Rexroth Valves

Rexroth valves are integral components in numerous industrial applications, renowned for their robust engineering and precise control of fluid dynamics. These valves are pivotal in sectors ranging from manufacturing to aerospace, where they ensure the seamless operation of machinery by regulating the flow of liquids and gases. The importance of Rexroth valves cannot be overstated, as they form the backbone of hydraulic and pneumatic systems used worldwide. The company Bosch Rexroth is a leading manufacturer in this field, pushing the boundaries of technology to deliver innovative solutions that meet the ever-evolving demands of modern industry.

Significance in Industrial Applications

The reliability and efficiency of Rexroth valves make them indispensable in industries that demand exact control over fluid power systems. Their ability to maintain stability under high pressure and varying temperatures ensures optimal performance, minimizing downtime and enhancing productivity. In manufacturing environments, for example, Rexroth valves are crucial in controlling processes such as injection molding, where precision control of hydraulic pressure directly affects the quality of the final product. Similarly, in the automotive sector, these valves play a vital role in assembly lines, ensuring that the machinery operates smoothly and efficiently.

Technological Advancements

Recent innovations in Rexroth valve technology have focused on enhancing automation and digital integration. Modern valves are equipped with advanced sensors and IoT capabilities, allowing for real-time monitoring and data analytics. This evolution supports predictive maintenance strategies, reducing the likelihood of unexpected failures. The integration of artificial intelligence (AI) in monitoring systems can further optimize performance by analyzing usage patterns and predicting when maintenance should be performed. For instance, algorithms can be developed to forecast valve wear based on operational data, thus extending the lifespan of the valves and reducing operational costs.

Market Presence and Supply Chain

Rexroth valves enjoy a significant market presence due to their reputation for quality and durability. The supply chain for these components is well-established, with numerous suppliers offering a range of products to meet diverse industrial needs. Regular updates and advancements in technology ensure that Rexroth valves remain at the forefront of fluid control solutions. The company’s global network allows for quick delivery and support, which is essential in industries where downtime can lead to significant financial losses. Additionally, Rexroth's commitment to sustainability is reflected in its manufacturing practices, ensuring that the production of valves aligns with environmental standards and goals.

| Feature | Benefit |

|---|---|

| Precision Engineering | Ensures accurate control of fluid dynamics. |

| Durability | Long-lasting performance under high stress. |

| Automation Compatibility | Facilitates integration with modern industrial systems. |

| IoT Integration | Enables real-time monitoring and data analysis. |

| Energy Efficiency | Reduces energy consumption and operational costs. |

| Versatility | Applicable in a variety of industries and conditions. |

| Customizability | Can be tailored to meet specific application requirements. |

Expert Insights on Rexroth Valves

Industry experts highlight the importance of choosing the right type of Rexroth valve for specific applications. Factors such as fluid type, pressure requirements, and environmental conditions play a critical role in valve selection. Consulting with specialists can ensure optimal system performance and longevity. For instance, hydraulic valves must be selected based on the viscosity of the fluid they will control; using the wrong valve can lead to inefficient operation or even system failure. Moreover, the selection process should also consider the potential for contamination in the fluid, which may require specific designs to prevent wear and damage.

Applications of Rexroth Valves

Rexroth valves are utilized in a wide range of applications across various industries. Below are some notable examples:

1. Manufacturing

In manufacturing, Rexroth valves are crucial in hydraulic systems, controlling the movement of machinery such as presses, conveyors, and robotic arms. Their precision allows for the exact positioning of components, which is vital in processes like assembly and packaging. For example, in the food and beverage industry, Rexroth valves help manage the flow of liquids in bottling plants, ensuring that products are filled accurately and efficiently.

2. Aerospace

The aerospace industry relies heavily on Rexroth valves for hydraulic systems in aircraft. These valves are designed to withstand extreme conditions, including high pressures and temperatures. They are integral in controlling wing flaps, landing gear, and other critical systems that require reliable operation. The safety and reliability of Rexroth valves are paramount, as any failure in these systems can have catastrophic consequences.

3. Automotive

In the automotive sector, Rexroth valves are used in assembly lines and testing equipment. They play a vital role in controlling the hydraulic systems that drive robotic arms, ensuring precise movements and placement of components during vehicle assembly. Furthermore, in testing applications, these valves help maintain consistent fluid pressure to simulate real-world driving conditions, allowing manufacturers to assess vehicle performance under various scenarios.

4. Energy Sector

In the energy sector, particularly in oil and gas, Rexroth valves are essential for controlling the flow of fluids in drilling and extraction processes. They operate in harsh environments, often exposed to corrosive substances and extreme pressures. Valves designed for these applications must not only perform reliably but also adhere to strict safety and environmental regulations. Additionally, Rexroth valves are used in renewable energy systems, such as wind turbines, where they help regulate hydraulic systems that control blade pitch and yaw.

Challenges in Using Rexroth Valves

While Rexroth valves are known for their reliability and performance, several challenges can arise in their use. Understanding these challenges is crucial for optimizing valve performance and ensuring long-term functionality.

1. Fluid Contamination

One of the primary challenges in using Rexroth valves is the risk of fluid contamination. Contaminants such as dirt, debris, and moisture can severely impair valve performance, leading to wear, leakage, and eventual failure. Implementing effective filtration systems and regular maintenance can mitigate this risk, ensuring that the fluid remains clean and free from harmful particles.

2. Temperature Variations

Rexroth valves are designed to operate within specific temperature ranges. Extreme variations in temperature can affect the viscosity of the fluid, impacting the valve's performance. For example, high temperatures may lead to fluid thinning, while low temperatures can cause thickening, making it difficult for the valve to control flow accurately. Proper thermal management and insulation can help maintain optimal operating conditions.

3. Pressure Fluctuations

Pressure fluctuations can pose significant challenges for Rexroth valves. Sudden spikes in pressure can lead to valve damage or failure, while insufficient pressure may result in inadequate flow control. To address this issue, implementing pressure relief valves and conducting regular system checks can help maintain stable pressure levels, ensuring reliable valve operation.

FAQs

What industries benefit very from Rexroth valves?

Rexroth valves are widely used in industries such as manufacturing, aerospace, automotive, and energy, where they contribute to efficient fluid management and system reliability. Their adaptability makes them suitable for various applications, including robotics, construction, and marine systems.

How do Rexroth valves enhance system automation?

By integrating with advanced control systems and IoT technologies, Rexroth valves facilitate seamless automation and provide valuable insights through data analytics. This integration allows for improved operational efficiency, reduced labor costs, and enhanced decision-making based on real-time data.

What maintenance is required for Rexroth valves?

Regular inspection and maintenance are crucial to ensure the longevity and performance of Rexroth valves. This includes checking for leaks, wear, and ensuring proper lubrication. Scheduled maintenance should also involve testing the valves to ensure they are functioning within specified parameters, allowing for early detection of potential issues.

How do I choose the right Rexroth valve for my application?

Choosing the right Rexroth valve involves considering several factors, including the type of fluid, pressure and temperature requirements, and the specific application needs. Consulting with experts in fluid dynamics and valve technology can provide valuable insights into selecting the most suitable valve for your system.

What are the benefits of IoT integration in Rexroth valves?

IoT integration in Rexroth valves provides several benefits, including real-time monitoring of valve performance, predictive maintenance capabilities, and enhanced data analytics. This technology enables operators to optimize fluid management, reduce downtime, and improve overall system efficiency.

In conclusion, Rexroth valves are a cornerstone of modern industrial systems, renowned for their precision and reliability. With ongoing advancements in technology, these valves continue to evolve, supporting more efficient and automated operations across various sectors. Understanding their functionalities, market dynamics, and maintenance requirements is essential for leveraging their full potential in industrial applications. As industries move towards greater automation and efficiency, the role of Rexroth valves will only become more critical, paving the way for innovations that further enhance their capabilities and applications.

Future Trends in Rexroth Valve Technology

The future of Rexroth valve technology is poised for significant advancements driven by the increasing demand for automation, efficiency, and sustainability in industrial applications. As industries evolve, Rexroth is expected to innovate in several key areas:

1. Smart Valves and AI Integration

As the Internet of Things (IoT) continues to reshape industrial processes, Rexroth valves are likely to become smarter. By integrating artificial intelligence, these valves can learn from operational data, enabling predictive maintenance and self-optimization. For example, AI algorithms can analyze historical performance data to forecast when a valve might fail or require maintenance, allowing operators to schedule service proactively and avoid unexpected downtime.

2. Enhanced Energy Efficiency

Energy efficiency is a growing concern in industrial operations. Rexroth is expected to focus on developing valves that minimize energy consumption while maximizing performance. Innovations may include advanced designs that reduce hydraulic losses and improve flow characteristics, ultimately leading to lower operational costs and a smaller carbon footprint.

3. Sustainable Materials and Eco-Friendly Practices

As industries strive to meet sustainability goals, Rexroth is likely to embrace eco-friendly materials and manufacturing practices. This may involve utilizing recycled materials in valve production and implementing greener processes that reduce waste and emissions. Such initiatives will not only appeal to environmentally conscious consumers but also align with global sustainability trends.

4. Customization and Modularity

In response to the diverse needs of various industries, Rexroth valves are expected to offer greater customization options. Modular designs will allow users to tailor valves to specific applications, enhancing versatility and adaptability. This approach can lead to more efficient systems, as operators can configure valves to meet unique operational requirements without the need for entirely new components.

5. Advanced Diagnostics and Monitoring

Future Rexroth valves may be equipped with sophisticated diagnostic tools that provide detailed insights into their performance and health. These tools can monitor parameters such as flow rate, pressure, and temperature, alerting operators to any deviations from normal operating conditions. This level of monitoring will enable more informed decision-making and help prevent failures before they occur.

Conclusion

Rexroth valves are more than just simple components; they are crucial elements of complex fluid power systems that drive efficiency and productivity across various industrial sectors. As technology advances, the capabilities of these valves will continue to expand, incorporating smart technologies, enhancing energy efficiency, and supporting sustainable practices. For businesses looking to maintain competitive advantages in increasingly automated and environmentally conscious markets, investing in Rexroth valves is a strategic decision that promises significant returns in performance and reliability. Understanding the current landscape and future trends in Rexroth valve technology will empower industries to leverage these innovations fully, ensuring they remain at the forefront of their respective fields.