Understanding Rexroth Valve Systems

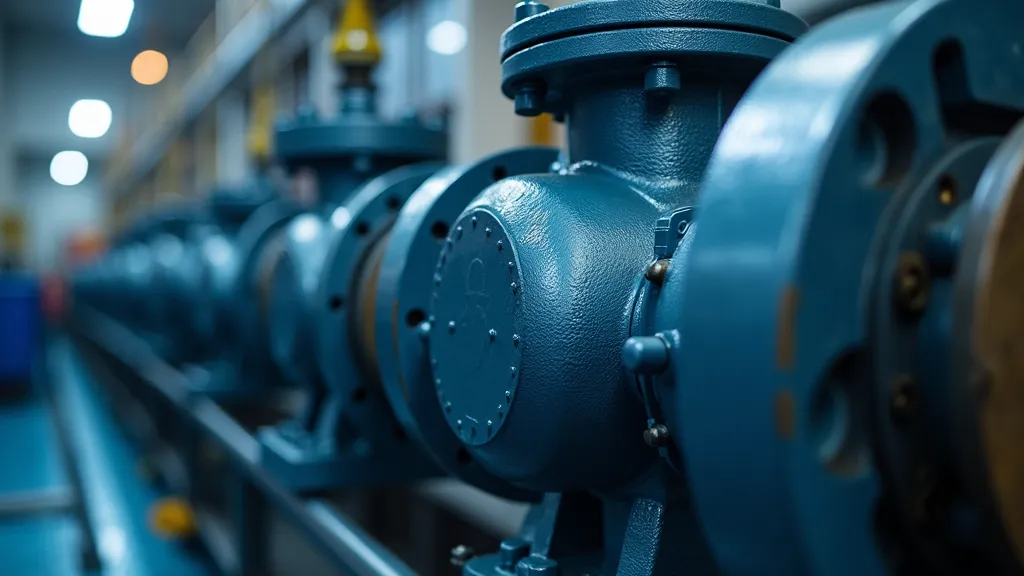

Rexroth valves are pivotal components in hydraulic systems, known for their efficiency and reliability. These valves, produced by Bosch Rexroth, are integral in various industries, from manufacturing to aerospace. With their precise control and durability, Rexroth valves ensure optimal performance in fluid power systems, making them a preferred choice for engineers and technicians worldwide.

Introduction to Rexroth Valves

Rexroth valves, produced by Bosch Rexroth, are renowned for their precision and durability, serving as fundamental components in hydraulic and pneumatic systems. These valves play a critical role in controlling fluid flow, pressure, and direction, making them indispensable in various industrial applications such as manufacturing, robotics, and aerospace. Rexroth's commitment to innovation and quality has positioned them as a leader in the hydraulic and pneumatic market, catering to diverse industries with tailored solutions that meet specific operational needs.

Key Features and Benefits

Rexroth valves are celebrated for their robust design and superior performance. Key features include high accuracy, rapid response times, and exceptional durability. These valves are engineered to withstand harsh environments and demanding operations, ensuring good reliability and minimal maintenance. The integration of advanced materials and cutting-edge technology in their design ensures that these valves can operate effectively in extreme conditions, such as high temperatures, corrosive environments, and fluctuating pressures.

Furthermore, many Rexroth valves are equipped with innovative diagnostic capabilities, allowing for real-time monitoring of performance metrics. This feature not only enhances operational efficiency but also simplifies troubleshooting and maintenance tasks, ultimately leading to reduced downtime and lower operational costs. The versatility of Rexroth valves also means that they can be easily integrated into existing systems, making them an excellent choice for retrofits and upgrades.

Types of Rexroth Valves

The Rexroth valve portfolio includes a wide range of types, each designed for specific applications:

- Directional Control Valves: These valves manage the direction of fluid flow within hydraulic systems, crucial for machinery movement and control. They can be operated manually, electrically, or hydraulically, depending on the specific application requirements.

- Pressure Control Valves: Essential for maintaining system pressure within safe limits, ensuring system integrity and safety. These valves can prevent overpressure situations, which can lead to equipment failure or safety hazards.

- Flow Control Valves: These regulate the flow rate of hydraulic fluid, optimizing the performance and efficiency of hydraulic systems. By adjusting the flow rate, they help maintain consistent speed and force in hydraulic actuators.

- Proportional Valves: These valves are designed to provide variable control over fluid flow, pressure, or direction. Their ability to adjust in real-time makes them ideal for applications requiring precise control.

- Cartridge Valves: Compact and versatile, cartridge valves can be used in various configurations and are often employed in mobile applications where space is limited.

Industry Applications

Rexroth valves are utilized across diverse industries, including:

- Manufacturing: Enhancing productivity and precision in automated production lines. In this sector, Rexroth valves facilitate smooth operation of machinery, ensuring that processes such as assembly, painting, and packaging are performed efficiently.

- Aerospace: Ensuring reliability in aircraft hydraulic systems for safe and efficient operation. Given the critical nature of aerospace applications, Rexroth valves are designed to meet stringent safety and performance standards.

- Construction: Providing robust control in heavy machinery, such as excavators and loaders. In construction, these valves help manage the various hydraulic functions that are essential for lifting, digging, and moving materials.

- Automotive: Supporting assembly lines and robotics in vehicle production, where precision and speed are paramount. Rexroth valves play a crucial role in controlling the hydraulic and pneumatic systems that drive robotic arms and other automated equipment.

- Food and Beverage: Ensuring hygienic and efficient operation in processing and packaging plants. The ability to provide precise control over fluid flow is critical in this sector to maintain quality and safety standards.

Choosing the Right Rexroth Valve

When selecting a Rexroth valve, consider factors such as system requirements, environmental conditions, and specific application needs. The process begins with a thorough analysis of the operating conditions, including the type of fluid being used, the required flow rates, and the pressure levels. Additionally, it is important to consider the compatibility of materials, especially in applications where corrosive fluids may be present.

Consulting with a knowledgeable supplier can help ensure the selection of the very suitable valve, optimizing system performance and longevity. Suppliers often have access to advanced simulation software that can predict how a particular valve will perform in a given application. This can be invaluable in making an informed decision. Furthermore, understanding any regulatory requirements that may apply to your industry is essential, as compliance can affect valve selection.

FAQs

- What makes Rexroth valves superior in the industry?

Rexroth valves are known for their precision, durability, and adaptability, catering to a wide range of industrial applications with high reliability. Their commitment to quality and innovation ensures that they remain at the forefront of technology in fluid power systems.

- How do I maintain Rexroth valves for optimal performance?

Regular inspections, proper lubrication, and adherence to manufacturer guidelines are essential for maintaining Rexroth valves. Additionally, it is important to monitor for signs of wear or damage and to replace components as necessary to prevent system failures.

- Can Rexroth valves be customized for specific applications?

Yes, Bosch Rexroth offers customization options to meet unique application requirements, ensuring the top fit for specific industrial needs. This can include modifications to valve size, functionality, or integration with existing systems.

- What types of fluids can Rexroth valves handle?

Rexroth valves can handle a wide variety of fluids, including hydraulic oils, water-based fluids, and even some corrosive substances, depending on the materials used in the valve construction. It is crucial to consult the specifications for each valve type to ensure compatibility.

- How can I troubleshoot issues with Rexroth valves?

Troubleshooting issues with Rexroth valves typically involves checking for leaks, verifying pressure settings, and ensuring that all connections are secure. Utilizing diagnostic tools can also help identify performance issues, allowing for quicker resolution.

Conclusion

Rexroth valves are a cornerstone in the realm of fluid power systems, offering unmatched performance and reliability. Their ability to operate under demanding conditions while maintaining precise control makes them an invaluable asset in various industrial sectors. By understanding the specific needs of your application and selecting the appropriate Rexroth valve, you can enhance system efficiency and longevity. Furthermore, the ongoing advancements in technology and materials used in the design of Rexroth valves will continue to improve their functionality and adaptability, keeping them relevant in an ever-evolving industrial landscape.

In addition to the aforementioned applications and benefits, it is worth noting that Rexroth is committed to sustainability and environmental responsibility. Their products are designed with energy efficiency in mind, helping to reduce the overall carbon footprint of industrial operations. By implementing Rexroth valves and systems, companies can not only improve their operational efficiency but also contribute to a more sustainable future.

Investing in Rexroth valves is not just a choice for immediate operational needs; it is also a long-term strategy for maintaining competitiveness in the market. As industries continue to push the boundaries of automation and efficiency, Rexroth remains a trusted partner, providing innovative solutions that empower businesses to thrive in challenging environments. Therefore, when considering your fluid power system needs, look towards Rexroth for reliable, effective, and forward-thinking valve solutions.