Understanding Rexroth Poppet Valves

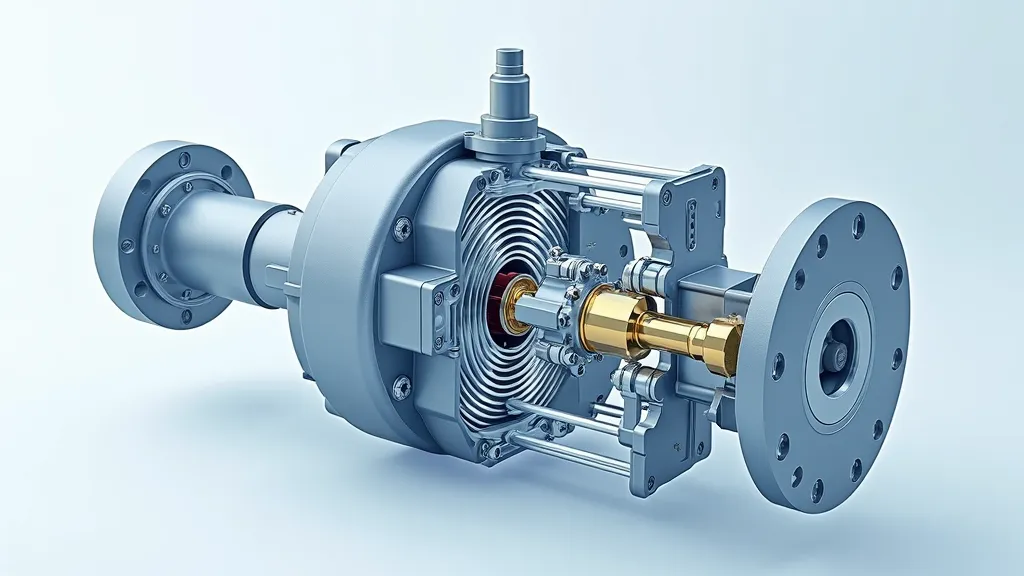

This guide delves into the intricacies of Rexroth Poppet Valves, essential components in hydraulic systems known for their reliability and precision. These valves play a critical role in controlling fluid flow, offering durability and efficiency in various industrial applications. Learn about their design, functionality, and why they are preferred in demanding environments.

The Importance of Rexroth Poppet Valves in Modern Industry

Rexroth Poppet Valves are crucial components in hydraulic systems, widely recognized for their exceptional reliability and precision. These valves are designed to control fluid flow, ensuring that hydraulic systems operate smoothly and efficiently. Their robust construction makes them ideal for use in demanding industrial environments where durability is paramount. In recent years, as industries increasingly rely on automation and advanced hydraulic systems, the significance of these valves has only grown.

Hydraulic systems form the backbone of many modern industrial processes, from manufacturing to construction, and the efficiency of these systems often hinges on the quality and performance of the hydraulic components used. Rexroth Poppet Valves excel in this regard, offering features that enhance the overall functionality of hydraulic systems.

What Makes Rexroth Poppet Valves Stand Out?

One of the defining characteristics of Rexroth Poppet Valves is their ability to provide precise control over fluid flow. This precision is achieved through a meticulously engineered design that minimizes leakage and maximizes performance. The valves are often used in applications where high reliability and reduced downtime are crucial, such as in manufacturing plants and heavy machinery. In many cases, the performance of hydraulic systems can be directly linked to the quality of the valves employed.

Another advantage of these valves is their durability. Constructed from high-quality materials, Rexroth Poppet Valves can withstand harsh conditions and prolonged use without significant wear. This makes them a cost-effective choice for industries looking to minimize maintenance costs while maximizing equipment longevity. For instance, in environments where dust, moisture, and extreme temperatures are prevalent, the use of robust components like Rexroth valves can drastically reduce the frequency of repairs and replacements.

Furthermore, Rexroth Poppet Valves are designed with user-friendliness in mind, featuring straightforward installation processes and compatibility with a variety of hydraulic systems. This ease of integration allows for quicker project turnarounds and reduces operational disruptions, making them a favorite among engineers and technicians alike.

Functionality and Design

Rexroth Poppet Valves operate by allowing or blocking fluid flow through a poppet mechanism, which is controlled by the movement of a plunger. This simple yet effective design ensures that the valve can quickly respond to changes in system pressure, providing smooth and consistent operation. The operation of poppet valves is typically binary—either fully open or fully closed—which allows for rapid actuation and reliable control of hydraulic circuits.

The design of these valves also incorporates features that enhance their performance, such as optimized flow paths and pressure-balancing mechanisms. These features help to minimize pressure drops and ensure that the valves operate efficiently even under varying load conditions. For example, in systems where pressure fluctuations are common, the pressure-balancing mechanisms help maintain consistent flow rates, which can be critical for processes that require exact timing and movement.

Moreover, the modular design of Rexroth Poppet Valves allows for easy customization and scalability. Depending on the specific requirements of a hydraulic system, different configurations, sizes, and specifications can be easily adapted. This modularity ensures that industries can tailor their hydraulic solutions to meet their operational needs without compromising on performance or reliability.

Applications of Rexroth Poppet Valves

These valves are used in a wide range of applications, thanks to their versatility and reliability. Common uses include:

- Industrial Automation: In automated systems, Rexroth Poppet Valves provide precise control of hydraulic actuators, ensuring smooth and accurate movement. This is particularly important in applications such as robotic assembly lines, where precision is critical for maintaining product quality.

- Construction Equipment: The robustness of these valves makes them ideal for use in heavy-duty construction machinery, where they help control hydraulic cylinders and motors. Equipment like excavators, bulldozers, and cranes rely on the reliable operation of poppet valves to perform tasks efficiently and safely.

- Manufacturing: In manufacturing processes, these valves ensure that hydraulic systems operate efficiently, reducing the risk of downtime. From injection molding machines to conveyor systems, the role of Rexroth Poppet Valves is integral in maintaining productivity.

- Aerospace and Defense: In highly regulated sectors such as aerospace and defense, the precision and reliability of hydraulic components are paramount. Rexroth Poppet Valves are often utilized in hydraulic systems for aircraft landing gear, missile systems, and other critical applications where failure is not an option.

- Marine Applications: The marine industry also benefits from the use of Rexroth Poppet Valves. These valves are used in hydraulic steering systems, deck machinery, and other applications where durable and reliable hydraulic control is necessary in harsh environments.

Comparing Rexroth Poppet Valves

| Feature | Rexroth Poppet Valve | Competitor Valves |

|---|---|---|

| Precision Control | High | Moderate to High |

| Durability | Excellent | Varies |

| Maintenance Needs | Low | Moderate |

| Cost-effectiveness | High | Varies |

| Response Time | Fast | Variable |

| Customization Options | Extensive | Limited |

Why Choose Rexroth Poppet Valves?

Choosing Rexroth Poppet Valves for your hydraulic systems means investing in quality and performance. These valves are designed to meet the demands of modern industry, providing reliable operation in even the very challenging conditions. Their proven track record and widespread use in various sectors underscore their capability and value.

Additionally, Rexroth offers comprehensive support and resources for their products, including technical documentation, installation guidelines, and troubleshooting assistance. This commitment to customer service further reinforces the attractiveness of Rexroth Poppet Valves, as users can rely on expert guidance when integrating these components into their systems.

Furthermore, as industries move towards more sustainable practices, the efficiency of hydraulic systems becomes increasingly important. Rexroth Poppet Valves contribute to energy savings by minimizing leakage and pressure drops, leading to reduced energy consumption and lower operational costs over time. This alignment with sustainability goals makes Rexroth an ideal choice for companies striving to improve their environmental footprint.

FAQs

- What industries benefit significantly from Rexroth Poppet Valves?

Industries such as manufacturing, construction, automation, aerospace, and marine sectors benefit significantly due to the valves' reliability and efficiency. Each of these sectors has unique demands, and Rexroth Poppet Valves deliver tailored solutions that enhance performance. - How do Rexroth Poppet Valves compare to other valve types?

They offer superior precision and durability, making them a preferred choice over other valve types in demanding applications. Unlike spool valves, which can be more complex and prone to leakage, Rexroth Poppet Valves provide a simpler, more robust solution. - What maintenance is required for these valves?

Rexroth Poppet Valves require minimal maintenance, primarily involving regular inspections and occasional part replacements to ensure optimal performance. This low maintenance requirement is a significant advantage for industries looking to reduce operational costs. - Can Rexroth Poppet Valves be customized?

Yes, Rexroth Poppet Valves offer extensive customization options to meet the specific requirements of various applications. This flexibility allows engineers to design hydraulic systems that are both efficient and effective. - What are the environmental benefits of using Rexroth Poppet Valves?

By minimizing leakage and pressure drops, Rexroth Poppet Valves contribute to reduced energy consumption, which is crucial for companies aiming to lower their carbon footprint and improve energy efficiency.

In conclusion, Rexroth Poppet Valves represent a pinnacle of engineering excellence in the field of hydraulic components. Their robust design, combined with precision and reliability, makes them indispensable in various industrial applications. For those seeking to enhance the performance and longevity of their hydraulic systems, these valves offer an unmatched solution. As industries continue to evolve and demand greater efficiency, the role of Rexroth Poppet Valves will undoubtedly become even more prominent, solidifying their place at the forefront of hydraulic technology.

Future Trends in Hydraulic Valve Technology

Looking ahead, the field of hydraulic valve technology is poised for significant advancements, driven by the increasing demands for efficiency, automation, and sustainability. Rexroth, as a leader in this sector, is at the forefront of these innovations. One trend is the integration of smart technology into hydraulic systems, allowing for real-time monitoring and control of valve performance. This can lead to enhanced diagnostics, predictive maintenance, and improved overall system efficiency.

Additionally, the use of advanced materials and manufacturing techniques, such as 3D printing and composite materials, is expected to revolutionize the design and production of hydraulic valves. These innovations will not only reduce manufacturing costs but also enhance performance characteristics, such as weight reduction and corrosion resistance.

Another area of focus is the development of more environmentally friendly hydraulic fluids and systems. As industries become more aware of their environmental impact, there will be a push towards using biodegradable or less toxic fluids in hydraulic applications. Rexroth Poppet Valves, designed to operate efficiently with these new fluids, will play a crucial role in this transition.

Moreover, the ongoing trend towards automation and Industry 4.0 will necessitate the evolution of hydraulic systems. Rexroth is likely to continue developing valves that can seamlessly integrate with digital control systems, allowing for enhanced data collection and analysis. This data-driven approach will enable industries to optimize their hydraulic systems in ways previously thought impossible.

Conclusion

In summary, Rexroth Poppet Valves are integral to the success of modern hydraulic systems across various industries. Their precision, durability, and efficiency make them an ideal choice for demanding applications, while their adaptability allows for customization to meet specific operational needs. As hydraulic technology continues to advance, Rexroth’s commitment to innovation will ensure that their poppet valves remain at the forefront of the industry, providing solutions that enhance productivity and sustainability.

For engineers, technicians, and industry leaders, investing in Rexroth Poppet Valves is not just a decision about purchasing components; it is a commitment to quality, reliability, and the future of hydraulic technology. As the landscape of industry evolves, so too will the capabilities and applications of these remarkable valves, ensuring they remain a vital part of hydraulic systems for years to come.