Understanding Rexroth Poppet Valves

This article explores the intricate details of Rexroth Poppet Valves, emphasizing their importance in controlling fluid flow in various industrial applications. As a leading component in hydraulic systems, these valves provide precise control and reliability, enhancing the efficiency and safety of machinery. The article delves into their design, functionality, and the advantages they offer in modern engineering.

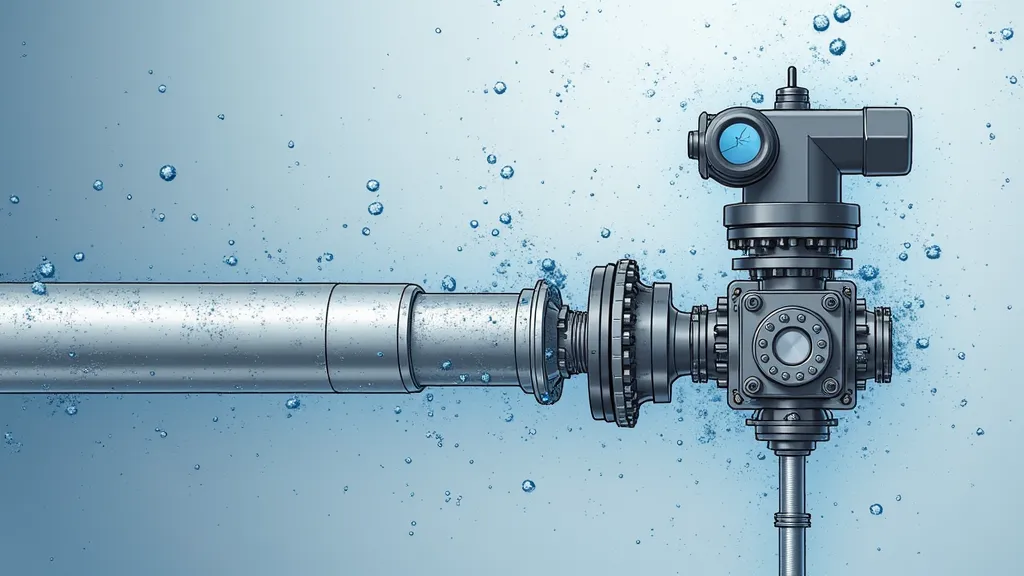

Introduction to Rexroth Poppet Valves

Rexroth Poppet Valves are critical components in hydraulic systems, renowned for their ability to control fluid flow with precision and reliability. These valves are integral to various industrial applications, ensuring efficiency and safety in machinery operations. As an essential part of the Bosch Rexroth product line, they are crafted to meet the highest standards of performance and durability. The unique design of these valves allows them to suit a wide range of hydraulic applications, providing solutions that cater to the needs of modern industry.

Design and Functionality

At the core of Rexroth Poppet Valves is a robust design that optimizes fluid flow control. These valves operate using a poppet mechanism, which allows for quick opening and closing, facilitating rapid response times in hydraulic circuits. The design minimizes leakage and ensures a tight seal, making them ideal for applications where precision is paramount. The poppet itself acts as a blocking element that seals against a seat, thus controlling the flow of fluid through the valve. This mechanism is particularly effective in preventing backflow, which is crucial in maintaining the integrity of hydraulic systems.

Furthermore, the materials used in constructing Rexroth Poppet Valves are selected for their ability to withstand various environmental factors such as temperature fluctuations, corrosion, and wear. This ensures that the valves maintain their performance over extended periods, even in demanding conditions. Advanced manufacturing processes and quality control measures are employed to ensure that each valve meets stringent industry standards, contributing to their reliability and long service life.

Advantages of Rexroth Poppet Valves

The benefits of using Rexroth Poppet Valves are manifold. They offer superior control over fluid dynamics, significantly enhancing the performance of industrial systems. Additionally, their durability reduces the need for frequent replacements, thus lowering maintenance costs. Moreover, their compact design allows for space-efficient installation in various settings. This is particularly advantageous in applications where space is at a premium, as it enables engineers and designers to optimize the layout of hydraulic systems without compromising performance.

Another significant advantage is the adaptability of Rexroth Poppet Valves. They can be tailored to fit specific operational requirements, including variations in pressure ratings and flow capacities. This flexibility makes them suitable for a wide range of applications, from small-scale machinery to large industrial setups. Furthermore, the simplicity of their design translates to ease of installation and troubleshooting, which is a considerable advantage for maintenance teams working in fast-paced environments.

Applications in Industry

Rexroth Poppet Valves find applications across multiple industries, including manufacturing, automotive, and aerospace. In the manufacturing sector, they are used to regulate hydraulic presses and injection molding machines, controlling the force and speed with which these machines operate. This regulation is vital for achieving high precision and repeatability in manufacturing processes, such as producing intricate components with tight tolerances.

In the automotive industry, they play a crucial role in transmission systems and braking mechanisms. The ability to control fluid flow precisely allows for smoother operation of automatic transmissions, enhancing vehicle performance and fuel efficiency. In braking systems, the reliability of poppet valves ensures that hydraulic pressure is maintained, providing consistent braking response and safety for drivers.

The aerospace sector also benefits significantly from Rexroth Poppet Valves. These valves are used in flight control systems and landing gear operations, where reliability and performance are non-negotiable. The extreme conditions experienced at high altitudes necessitate components that can withstand significant stress while maintaining operational integrity. Rexroth’s commitment to quality ensures that their valves meet the rigorous requirements of aerospace applications.

A Comparison of Valve Types

| Valve Type | Key Feature | Typical Application |

|---|---|---|

| Poppet Valve | Quick response time | Hydraulic circuits |

| Ball Valve | Low-pressure drop | Pipeline systems |

| Gate Valve | Linear flow control | Water supply systems |

| Check Valve | Prevents backflow | Pumping systems |

| Solenoid Valve | Electromechanical operation | Automated systems |

Factors to Consider When Choosing a Valve

When selecting a poppet valve, several factors must be considered to ensure optimal performance. These include the operating pressure and temperature, the type of fluid being controlled, and the specific requirements of the application. Evaluating these elements will help in choosing a valve that meets the operational demands efficiently.

Additionally, it is essential to consider the flow rate required for the application. Flow rate influences not only the size of the valve but also the design and materials used. For instance, high flow applications may require larger valves or those designed with specific port configurations to facilitate better flow dynamics. Another critical aspect is the compatibility of the valve materials with the fluid being used, as certain fluids can cause corrosion or degradation of materials over time.

Another crucial factor is the installation environment. Poppet valves may be used in harsh conditions, including extreme temperatures or exposure to corrosive substances. Selecting materials and designs that can withstand these conditions is vital for ensuring long-term reliability. Furthermore, the ease of maintenance should be considered, as valves that require complex disassembly for servicing can lead to increased downtime in industrial settings.

FAQs

Q: What makes Rexroth Poppet Valves unique compared to other valve types?

A: Rexroth Poppet Valves are distinguished by their rapid response time and precise control capabilities, making them suitable for high-performance applications. Their design allows for minimal leakage and excellent sealing properties, which enhance their effectiveness in hydraulic systems.

Q: Can Rexroth Poppet Valves be used in high-pressure systems?

A: Yes, these valves are designed to withstand high pressures, making them ideal for demanding industrial environments. They are rigorously tested to ensure they meet the performance requirements of high-pressure applications, ensuring safety and reliability.

Q: How often should Rexroth Poppet Valves be maintained?

A: Regular maintenance intervals depend on the specific application and operating conditions. However, their durable design typically requires less frequent maintenance than other valve types. It is advisable to establish a maintenance schedule based on manufacturer recommendations and operational experience.

Q: Are Rexroth Poppet Valves environmentally friendly?

A: Rexroth is committed to sustainability and environmentally friendly practices. The materials used in the manufacturing of poppet valves are selected to minimize environmental impact, and the longevity of these valves contributes to reduced waste over time. Additionally, their efficiency in hydraulic systems can lead to lower energy consumption.

Conclusion

Rexroth Poppet Valves are a cornerstone in the realm of hydraulic systems, offering unparalleled control and reliability. Their application across various industries highlights their versatility and importance in modern engineering. By understanding their design and functionality, industries can leverage these valves to optimize operations and ensure safety in their processes. As technology advances, the role of poppet valves will continue to evolve, paving the way for even more innovative hydraulic solutions. The continued development and refinement of Rexroth Poppet Valves will undoubtedly lead to enhanced performance and reliability, further solidifying their status as a leading choice among hydraulic components.

Furthermore, as industries increasingly prioritize automation and smart technologies, the integration of Rexroth Poppet Valves into these systems will facilitate improved process control and efficiency. The future of hydraulic systems may see even more advanced features, such as electronic monitoring and real-time diagnostics, which will further enhance the effectiveness of these valves. In conclusion, Rexroth Poppet Valves are not just components; they are essential players in the orchestration of modern industrial operations, driving productivity and innovation across various sectors.