Understanding Rexroth Poppet Valve Systems

Rexroth Poppet Valves are integral components in hydraulic systems, known for their reliability and efficiency in controlling fluid flow. These valves, designed by Bosch Rexroth, are used across various industries for precise motion control applications. This article delves into the functionality, advantages, and applications of Rexroth Poppet Valves, offering insights into their significance in industrial operations.

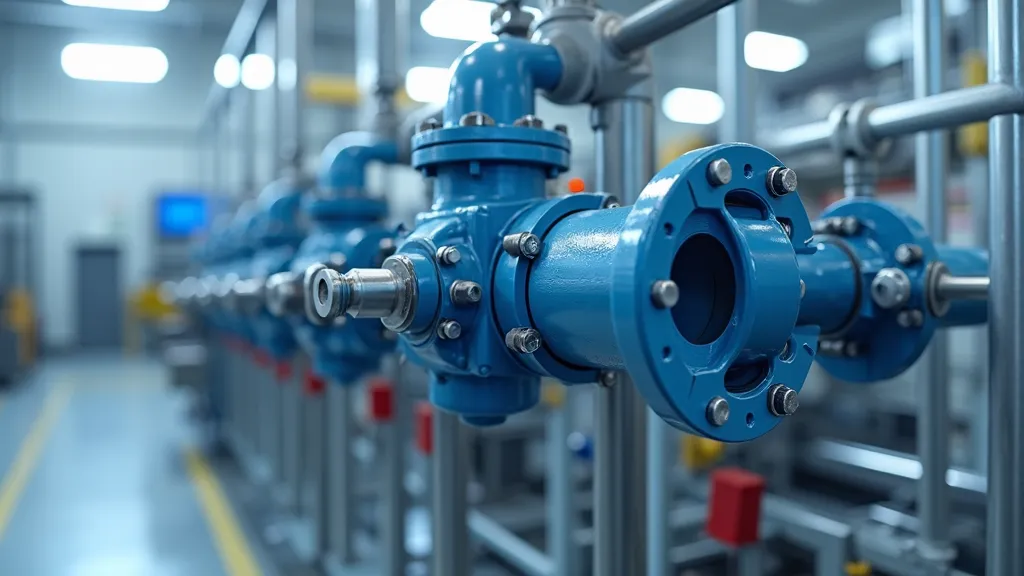

Introduction to Rexroth Poppet Valves

Rexroth Poppet Valves, designed by Bosch Rexroth, are pivotal in the realm of hydraulic systems. Known for their robust construction and reliable performance, these valves are essential for managing flow and pressure in various industrial applications. The precision and durability of Rexroth Poppet Valves make them a preferred choice in sectors that demand high-performance standards. Understanding the intricacies of these valves can provide deeper insights into their functionality and applications, enhancing the operational efficiency of hydraulic systems across multiple industries.

Functionality and Design

Poppet valves function by allowing or obstructing fluid flow through a system. The design typically includes a sealing element that opens or closes against a seat, managing the passage of liquids or gases. This mechanism is particularly effective in controlling the direction and rate of fluid flow, making it a versatile component in hydraulic systems. The core elements of a Rexroth Poppet Valve include the valve body, the poppet, the seat, and the actuator mechanism, each of which plays a crucial role in the valve's operation.

The valve body is typically constructed from high-strength materials to withstand the pressures and stresses of hydraulic systems. The poppet, which is the moving part of the valve, is designed to create a tight seal when closed, preventing any fluid leakage. The seat is where the poppet makes contact to block flow, and the actuator mechanism, which can be manual or automatic, controls the movement of the poppet. This simple yet effective design ensures that the valve operates efficiently under various conditions, making it a reliable choice for engineers and system designers.

Advantages of Using Rexroth Poppet Valves

Rexroth Poppet Valves offer numerous advantages, including:

- Reliability: These valves are designed to withstand high pressure and demanding conditions, ensuring good operation without frequent maintenance. Their robust construction allows them to endure the rigors of heavy industrial use, making them a trusted choice for critical applications.

- Efficiency: The precise control of fluid flow minimizes energy loss and enhances system efficiency. This aspect is particularly important in industries where operational costs are closely monitored, as efficient fluid management can lead to significant savings over time.

- Versatility: Suitable for various applications, including industrial machinery, automotive systems, and aerospace technology. The adaptability of Rexroth Poppet Valves allows them to be integrated into diverse systems, providing flexibility for engineers and designers.

- Simplicity: Their straightforward design facilitates easy installation and integration into existing systems. This ease of use reduces the time and labor costs associated with installation, making these valves a cost-effective solution for many applications.

- Compact Design: The compact design of Rexroth Poppet Valves allows for space-saving installations, which is an essential consideration in modern engineering where space is often at a premium. This feature makes it easier to incorporate these valves into tight spaces without sacrificing performance.

- Low Leakage Rates: The sealing technology employed in Rexroth Poppet Valves minimizes leakage, ensuring that systems operate more efficiently and sustainably. Lower leakage rates contribute to better system performance and reduced environmental impact.

Applications in Industry

Rexroth Poppet Valves are utilized across multiple industries due to their adaptability and performance. Common applications include:

- Manufacturing: Used in automation and machinery for precise movement and control. In manufacturing, these valves help regulate the hydraulic systems that operate machinery, ensuring that processes run smoothly and efficiently.

- Automotive: Integral in braking systems and fuel management. In automotive applications, Rexroth Poppet Valves contribute to safety and performance by controlling fluid flow in critical systems such as brakes and fuel injection.

- Aerospace: Critical for controlling hydraulic systems in aircraft. The aerospace sector requires components that can operate reliably under extreme conditions, and Rexroth Poppet Valves meet these stringent requirements, ensuring the safety and efficiency of flight operations.

- Energy: Employed in oil and gas operations to manage flow and pressure. In the energy sector, these valves play a vital role in controlling fluid dynamics in extraction and processing operations, contributing to the overall efficiency of energy production.

- Construction: Used in heavy machinery for controlling hydraulic systems. The construction industry relies on powerful hydraulic machinery, and Rexroth Poppet Valves help manage the hydraulic circuits that drive these machines, ensuring optimal performance on job sites.

- Agriculture: Essential for hydraulic systems in tractors and other farming equipment. In the agricultural sector, these valves help regulate the hydraulic operations of equipment, improving efficiency and productivity in farming practices.

Comparison of Valve Types

| Valve Type | Description | Applications |

|---|---|---|

| Poppet Valve | Uses a sealing element to control flow. | Industrial, automotive, aerospace. |

| Ball Valve | Utilizes a spherical ball to control flow. | Water systems, chemical processes. |

| Gate Valve | Employs a gate to halt flow. | Water distribution, wastewater plants. |

| Check Valve | Allows flow in one direction only. | Pipelines, fuel systems. |

| Throttle Valve | Regulates flow rate in a system. | Air conditioning, fluid control. |

This comparison highlights the unique characteristics of different valve types, showcasing the specific functionalities that each type offers. While poppet valves excel in precise flow control, other valves like ball valves and gate valves serve distinct purposes based on the requirements of the systems in which they are used. Understanding these differences helps engineers select the appropriate valve type for their applications.

FAQs

- What is the primary function of a Rexroth Poppet Valve?

Its primary function is to control the flow and pressure of fluids within a hydraulic system. This control is crucial for maintaining the desired performance and efficiency of the entire hydraulic circuit.

- How do Rexroth Poppet Valves improve system efficiency?

By providing precise control over fluid movement, these valves minimize energy loss and enhance overall system performance. The ability to regulate flow accurately ensures that hydraulic systems operate at optimal levels, reducing waste and improving productivity.

- Can Rexroth Poppet Valves be used in extreme conditions?

Yes, they are designed to withstand high pressures and harsh environments, making them suitable for demanding applications. Their robust construction and high-quality materials ensure reliability even in challenging conditions, such as extreme temperatures and corrosive environments.

- What maintenance is required for Rexroth Poppet Valves?

Regular inspection and maintenance are recommended to ensure optimal performance. This includes checking for leaks, verifying the integrity of seals, and ensuring that the actuator mechanism functions properly. Routine maintenance can help extend the life of the valve and prevent costly downtimes.

- How do I select the right Rexroth Poppet Valve for my application?

Selection should be based on several factors, including the required flow rate, pressure ratings, and compatibility with the fluids being used. Consulting the manufacturer's specifications and guidelines can help in identifying the most suitable valve for your specific application.

Conclusion

Rexroth Poppet Valves are indispensable in modern hydraulic systems, offering unparalleled reliability and efficiency. Their ability to manage complex fluid dynamics with precision makes them a cornerstone in industrial applications. As industries continue to evolve, the demand for high-performance components like Rexroth Poppet Valves is expected to grow, solidifying their role in future technological advancements. Furthermore, the continuous innovation in valve technology and materials promises to enhance their performance, longevity, and adaptability in an ever-changing industrial landscape.

As we look ahead, it is crucial for engineers and system designers to stay informed about the latest developments in valve technology. Understanding the advancements in materials science, manufacturing processes, and control technologies will be vital in optimizing hydraulic systems for future applications. By leveraging the benefits of Rexroth Poppet Valves and other advanced hydraulic components, industries can achieve greater efficiency, sustainability, and performance, paving the way for a more productive and technologically advanced future.

In summary, Rexroth Poppet Valves not only fulfill a fundamental role in fluid control but also represent a significant advancement in hydraulic technology. Their continued use and evolution will undoubtedly support the growth and innovation of various sectors, driving improvements in machinery, automation, and overall operational efficiency.