Understanding Rexroth Servo Valves

This guide delves into the intricacies of Rexroth Servo Valves, pivotal components in industrial automation known for their precision and reliability. These valves are essential in controlling hydraulic fluid flow, significantly impacting machinery performance across various sectors. This exploration includes their functionality, applications, and advantages, providing a comprehensive understanding.

Introduction to Rexroth Servo Valves

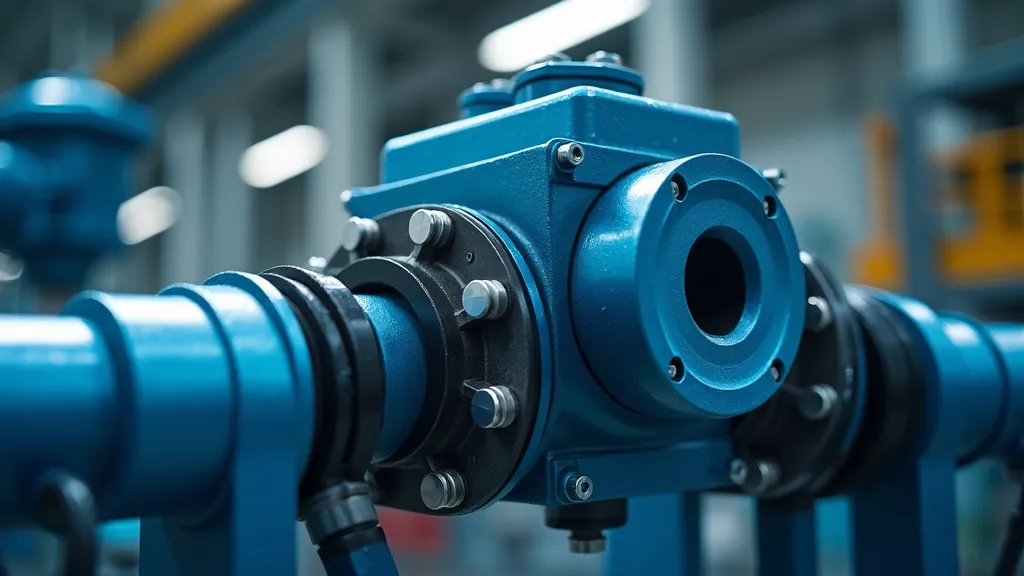

In the realm of industrial automation, Rexroth Servo Valves play a crucial role in enhancing the precision and efficiency of machinery. These valves are designed to control hydraulic fluid flow, which is vital in achieving optimal performance in various industrial applications. Known for their reliability and cutting-edge technology, Rexroth Servo Valves are a preferred choice among engineers and industry professionals. The importance of these valves extends beyond just functionality; they are integral in driving innovation in automation technologies.

Rexroth, a brand under Bosch, has a long-standing reputation for excellence in hydraulic systems and components. The Servo Valves produced by Rexroth are not merely components of machinery; they represent a culmination of years of research and development aimed at addressing the evolving needs of industrial processes. Their applications range from simple motion control systems to complex industrial automation frameworks, demonstrating their versatility and significance in modern manufacturing.

Core Functionality and Applications

The primary function of a Rexroth Servo Valve is to regulate the flow and pressure of hydraulic fluids within a system. This regulation is essential for the accurate movement of mechanical components, making these valves indispensable in industries such as manufacturing, aerospace, and automotive. By ensuring smooth and precise motion control, these valves enhance the overall productivity and safety of industrial operations.

In manufacturing, for example, Rexroth Servo Valves are often employed in CNC machines where precise control over the positioning of cutting tools is necessary. The ability to finely tune the flow of hydraulic fluid allows for intricate designs and high-quality finishes on products ranging from automotive parts to consumer goods. In the aerospace sector, these valves are crucial for controlling wing flaps and landing gear systems, where reliability and precision can impact safety and performance dramatically.

Furthermore, in the automotive industry, Rexroth Servo Valves are used in assembly lines and robotic applications where accurate positioning and speed control are vital. Their implementation can lead to significant improvements in production rates and reductions in waste, aligning with the industry's push towards lean manufacturing practices. The versatility of Rexroth Servo Valves means they can be adapted to a wide range of applications, further emphasizing their importance across various sectors.

Advantages of Rexroth Servo Valves

Rexroth Servo Valves offer numerous advantages that make them a standout choice in the industry. Their high precision and responsiveness allow for accurate control, which is crucial in applications requiring fine adjustments. This capability is particularly beneficial in systems where small changes can lead to significant differences in output quality or performance. Additionally, their robust construction ensures durability and longevity, reducing maintenance costs and downtime. The versatility of these valves also allows them to be integrated into a wide range of systems, providing flexibility in design and functionality.

One of the key strengths of Rexroth Servo Valves is their ability to operate under varying conditions without compromising performance. They are designed to handle different temperatures, pressures, and fluid types, which is essential in industries where operational environments can be unpredictable. Furthermore, the technology employed in these valves often includes advanced electronic controls that facilitate real-time monitoring and adjustments, enhancing operational efficiency.

Moreover, Rexroth Servo Valves are engineered for energy efficiency. Their precise control mechanisms reduce energy consumption compared to conventional hydraulic systems. This aspect not only results in cost savings for businesses but also aligns with the growing emphasis on sustainability in industrial processes. As companies strive to reduce their carbon footprint, the adoption of energy-efficient solutions like Rexroth Servo Valves becomes increasingly important.

Technical Insights

From an engineering perspective, Rexroth Servo Valves are built with advanced materials and technologies that contribute to their superior performance. The use of high-quality materials ensures minimal wear and tear, while cutting-edge electronic control systems provide real-time feedback for enhanced accuracy. These technical attributes make Rexroth Servo Valves a reliable component in any hydraulic system.

The engineering behind Rexroth Servo Valves includes sophisticated designs that allow for high-frequency responses. This means that they can quickly adapt to changing demands in hydraulic flow, making them ideal for dynamic applications where conditions can shift rapidly. Their design often incorporates features such as dual-stage control, which improves responsiveness and stability, further enhancing their application in high-precision environments.

Additionally, the integration of smart technology into Rexroth Servo Valves allows for predictive maintenance, which is a growing trend in industrial operations. By utilizing sensors and data analytics, these valves can provide insights into their performance and alert operators to potential issues before they escalate into serious problems. This proactive approach not only maximizes uptime but also prolongs the life of the valve itself, providing further cost savings over time.

Comparative Analysis

| Feature | Rexroth Servo Valve | Competitor Valve |

|---|---|---|

| Precision | High | Moderate |

| Durability | Excellent | Good |

| Integration Flexibility | Wide Range | Limited |

| Maintenance Costs | Low | Moderate |

| Energy Efficiency | High | Moderate |

| Response Time | Fast | Variable |

This comparative analysis illustrates the strengths of Rexroth Servo Valves in key performance categories. The high precision and durability of these valves make them a preferred choice in applications where performance is critical. The integration flexibility allows for easier incorporation into existing systems, making them suitable for retrofitting older machinery without significant modifications.

The low maintenance costs associated with Rexroth Servo Valves stem from their robust construction and advanced engineering, which minimizes the need for frequent repairs and replacements. The energy efficiency of these valves is also a significant advantage, especially in industries where reducing operational costs and environmental impact is a priority.

Furthermore, the fast response time of Rexroth Servo Valves gives them an edge in applications where rapid adjustments are necessary, such as in robotics or high-speed manufacturing processes. This combination of features positions Rexroth Servo Valves as a leading choice for industries looking to optimize their hydraulic systems.

Industry Adoption and Performance

The adoption of Rexroth Servo Valves in industrial settings has been bolstered by their proven performance and reliability. According to industry reports, companies utilizing these valves have reported increased efficiency and reduced operational costs. The seamless integration of these valves into existing systems is another factor driving their widespread use in the industry.

Many manufacturers have documented case studies showcasing the impact of Rexroth Servo Valves on their operations. For instance, a major automotive manufacturer implemented Rexroth Servo Valves in their assembly line, resulting in a 30% increase in production speed while maintaining product quality. Such improvements are not isolated; they reflect a broader trend of enhanced performance across various sectors as businesses adopt advanced hydraulic solutions.

Moreover, the feedback from users highlights the significant reduction in downtime associated with Rexroth Servo Valves. With their low maintenance requirements and high reliability, companies find that these valves not only enhance productivity but also contribute to a safer workplace by minimizing the risk of equipment failures. This aspect is particularly crucial in industries where safety regulations are stringent, and operational disruptions can lead to substantial financial losses.

As industries continue to evolve, the demand for components that can keep pace with technological advancements grows. Rexroth Servo Valves have positioned themselves well to meet this demand, thanks to their continuous innovation and commitment to quality. The integration of smart technologies and IoT capabilities into these valves is a testament to their forward-thinking approach, allowing them to remain competitive in a rapidly changing market.

Frequently Asked Questions (FAQs)

- What are the primary applications of Rexroth Servo Valves?

They are primarily used in industries requiring precise hydraulic control, such as manufacturing, aerospace, and automotive. These valves are particularly effective in applications that demand high precision and reliability, enhancing operational efficiency. - How do Rexroth Servo Valves enhance system performance?

By providing precise control of hydraulic fluid flow, they ensure accurate and smooth operation of machinery. This precision control allows for better performance in various applications, including CNC machining, robotic systems, and automated assembly lines. - What factors should be considered when selecting a Rexroth Servo Valve?

Consider the application's specific requirements, such as pressure range, flow rate, and environmental conditions. It is also essential to evaluate the integration capabilities with existing systems and the expected maintenance needs of the valve. - Are Rexroth Servo Valves easy to maintain?

Yes, their robust design and construction result in low maintenance needs. Regular inspections and basic upkeep can ensure their longevity, making them a cost-effective choice for many industries. - What innovations are driving the development of Rexroth Servo Valves?

Recent advancements include the integration of IoT technologies for predictive maintenance, improved materials for enhanced durability, and advanced control algorithms for better performance under varying conditions. - How do Rexroth Servo Valves contribute to energy efficiency?

By allowing precise control of hydraulic fluid flow, they minimize energy waste, leading to lower operational costs and a reduced carbon footprint, aligning with the sustainability goals of many organizations.

Conclusion

Rexroth Servo Valves stand out as a top choice for industries seeking efficiency and precision in hydraulic systems. Their advanced technology, coupled with robust construction, makes them reliable components that contribute significantly to the performance and safety of industrial operations. As industries continue to evolve, the demand for high-performance components like Rexroth Servo Valves is expected to rise, further cementing their position as a leader in hydraulic control solutions.

In conclusion, the role of Rexroth Servo Valves in shaping the future of industrial automation cannot be overstated. With their ability to enhance precision, reduce operational costs, and increase safety, they are not just a component of machinery; they are a vital part of the evolution of modern manufacturing. As new technologies emerge and industries adapt to changing demands, Rexroth will continue to be at the forefront, providing solutions that meet the needs of tomorrow's automation challenges. The commitment to innovation, quality, and performance ensures that Rexroth Servo Valves will remain a preferred choice among engineers and industry leaders for years to come.