Understanding Rexroth Servo Valve Dynamics

This article provides an in-depth analysis of the Rexroth Servo Valve, a crucial component in hydraulic and pneumatic systems. Known for their precision and reliability, these valves play a pivotal role in controlling fluid flow in various industrial applications. The guide delves into the technical aspects, industry applications, and maintenance practices for maximizing efficiency and longevity.

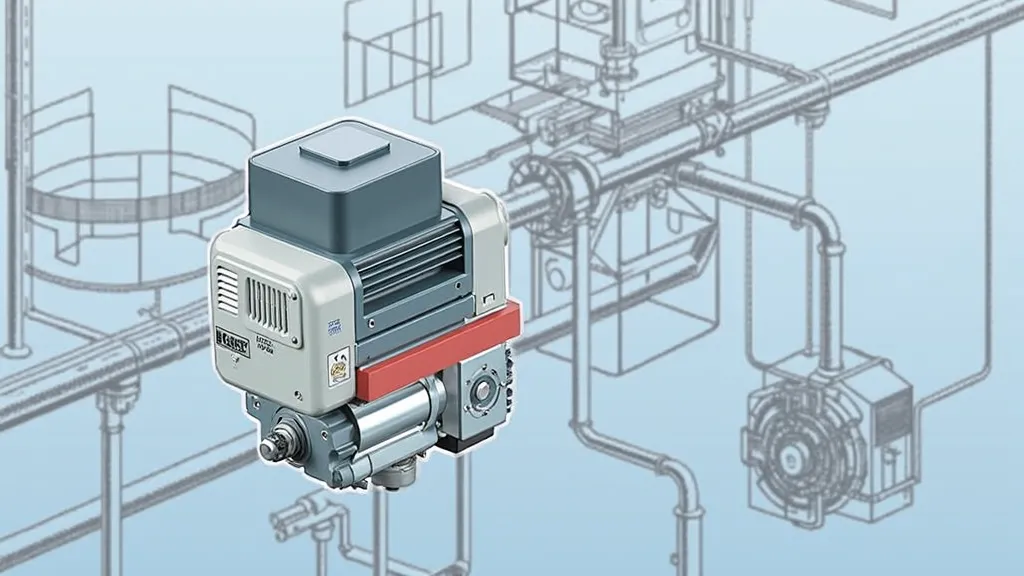

Introduction to Rexroth Servo Valves

The Rexroth Servo Valve is a pivotal component in modern hydraulic systems, designed to offer precise control over fluid flow and pressure. These valves are integral in applications requiring high levels of accuracy and responsiveness, making them indispensable in industries such as aerospace, automotive, and manufacturing. Their ability to convert electrical signals into mechanical movement allows for seamless integration into automated systems, enhancing overall productivity and efficiency. In the context of increasingly automated environments, Rexroth Servo Valves stand out due to their exceptional performance and adaptability, ensuring that they meet the rigorous demands of contemporary engineering challenges.

Technical Specifications and Features

The Rexroth Servo Valve is renowned for its robust construction and precision engineering. Typically, these valves feature a spool design that can vary the flow rate based on the electrical input signal. Key features include high-frequency response, excellent linearity, and minimal hysteresis, which contribute to their superior performance in dynamic applications. The valves are available in various sizes and configurations, catering to diverse industrial needs and ensuring compatibility with different system requirements.

In addition to their fundamental features, Rexroth Servo Valves are equipped with advanced functionalities such as feedback systems that provide real-time monitoring of valve performance. This feedback loop is crucial for maintaining operational accuracy and making adjustments on the fly. Furthermore, the valves often incorporate sophisticated electronics, including integrated controllers that enhance their performance in closed-loop systems, allowing for more complex control strategies. This level of sophistication makes these valves particularly suited for applications that require not just speed but also precision and reliability.

Industry Applications

Rexroth Servo Valves are utilized across a broad spectrum of industries. In the aerospace sector, they are critical for controlling flight surfaces and landing gear systems. The automotive industry employs these valves in testing and simulation environments to replicate real-world conditions accurately. Manufacturing processes benefit from their precision in controlling machinery movements, ensuring product quality and operational safety. The versatility of Rexroth Servo Valves makes them a preferred choice in any setting demanding precise fluid control.

In the realm of robotics, these valves play a vital role in enabling the precise movements required for tasks ranging from assembly to painting. In semiconductor manufacturing, where cleanroom environments and exacting tolerances are paramount, Rexroth Servo Valves help regulate fluid dynamics in processes such as etching and deposition. Additionally, in the renewable energy sector, these valves are employed to manage hydraulic systems in wind turbines and solar tracking systems, demonstrating their adaptability across various applications. The continuous evolution of technology further propels the need for such advanced components, leading to innovations that enhance their functionality and application scope.

Maintenance and Top Practices

To maintain the optimal performance of Rexroth Servo Valves, regular maintenance is crucial. This includes routine inspections for wear and tear, ensuring clean hydraulic fluid to prevent contamination, and calibrating the valves to maintain accuracy. Employing predictive maintenance strategies can preemptively address potential issues, minimizing downtime and extending the valve's lifespan. It is also advisable to work closely with authorized suppliers for genuine parts and expert servicing.

Moreover, implementing a structured maintenance schedule can greatly enhance the reliability of these valves. This schedule should include not only inspections but also functionality tests to verify that the servo valves respond accurately to control signals. Using diagnostic tools, such as flow meters and pressure gauges, can provide insights into the valve’s performance. Furthermore, documenting maintenance activities can help identify patterns that may indicate emerging issues, allowing for timely interventions. Training personnel on the correct handling and maintenance of these valves further ensures that they operate within their optimal parameters, thus safeguarding investments and enhancing operational efficiencies.

Comparison Table: Key Features of Rexroth Servo Valves

| Feature | Description |

|---|---|

| High-Frequency Response | Allows rapid adjustments to flow and pressure, ideal for dynamic systems. |

| Minimal Hysteresis | Ensures precise control and repeatability of valve operations. |

| Robust Construction | Designed to withstand demanding industrial environments. |

| Integrated Feedback Systems | Provides real-time monitoring and adjustments for optimal performance. |

| Advanced Electronics | Includes integrated controllers for enhanced functionality in complex systems. |

FAQs

Q: What industries benefit very from Rexroth Servo Valves?

A: Industries such as aerospace, automotive, and manufacturing benefit significantly due to the valves' precision and reliability. Moreover, robotics, semiconductor manufacturing, and renewable energy sectors also utilize these valves to optimize their operations and ensure high-performance standards.

Q: How often should Rexroth Servo Valves be serviced?

A: Regular maintenance is recommended every 6 to 12 months, depending on the application intensity and environmental conditions. In high-demand settings, more frequent checks may be necessary to ensure continued performance and reliability.

Q: Can Rexroth Servo Valves be integrated into existing systems?

A: Yes, these valves are designed for compatibility and can be integrated into existing hydraulic or pneumatic systems with minimal adjustments. This flexibility allows businesses to upgrade their systems without major overhauls, thereby saving time and costs.

Q: What are the common signs that a Rexroth Servo Valve needs servicing?

A: Common signs include erratic valve performance, abnormal noises, leaks, and failure to respond to input signals. Regular observance of these symptoms can facilitate early diagnosis and minimize downtime.

Q: Are there any specific environmental considerations for Rexroth Servo Valves?

A: Yes, factors such as temperature, humidity, and contamination levels can affect valve performance. It is crucial to ensure that the operating environment aligns with the manufacturer’s specifications to avoid premature wear or failure.

In conclusion, Rexroth Servo Valves are a cornerstone in the realm of industrial automation and control, offering unmatched precision and reliability. By understanding their technical nuances and adhering to top maintenance practices, industries can harness the full potential of these sophisticated components, driving efficiency and innovation in their operations. As technology continues to advance, the role of these valves is likely to evolve, paving the way for even more innovative applications and solutions that will shape the future of industrial processes.

Future Trends in Servo Valve Technology

The field of servo valve technology is rapidly evolving, driven by advancements in electronics, materials science, and system integration. One of the most significant trends is the integration of IoT (Internet of Things) capabilities into servo valves. This development allows for real-time data collection and analysis, enabling predictive maintenance strategies that can anticipate failures before they occur. The ability to monitor valve performance remotely enhances operational efficiency and reduces downtime, making it a valuable asset in modern manufacturing and automation environments.

Another notable trend is the move towards miniaturization. As industries strive for compact and efficient designs, servo valves are becoming smaller while still maintaining high performance. This trend is particularly relevant in sectors such as robotics and aerospace, where space is at a premium, and every component must deliver maximum functionality within a limited footprint. Advances in materials, such as lightweight composites and advanced alloys, are facilitating this miniaturization without compromising strength or reliability.

Moreover, the push for sustainability is influencing the design and usage of servo valves. Manufacturers are increasingly focused on creating energy-efficient systems that minimize waste and reduce environmental impact. This includes developing servo valves that consume less energy while providing the same level of performance, as well as designing systems that utilize renewable energy sources. The synergy between energy efficiency and high-performance control systems is becoming a critical factor in the selection and application of servo valves.

Conclusion

Rexroth Servo Valves represent the pinnacle of hydraulic control technology, combining precision, reliability, and advanced features to meet the demands of modern industries. Their broad applicability across various sectors underscores their versatility and importance in contemporary engineering. As technology continues to evolve, these valves are set to play an even more critical role in automation and control, contributing to the advancement of smart manufacturing, robotics, and sustainable practices.

By investing in high-quality Rexroth Servo Valves and adhering to best practices in maintenance and operation, industries can not only enhance their productivity but also ensure that they remain competitive in an increasingly automated and technology-driven landscape. The future of servo valve technology looks promising, with innovations that will undoubtedly lead to even greater efficiencies and capabilities in the years to come.