Understanding Rexroth Servo Valves

Rexroth servo valves are critical components in modern industrial systems, enabling precise control of fluid flow and pressure. These valves are essential in automation and manufacturing sectors, where they enhance performance and efficiency. This article delves into their functionality, benefits, and applications, providing professionals with in-depth insights into their role in contemporary industry.

Introduction to Rexroth Servo Valves

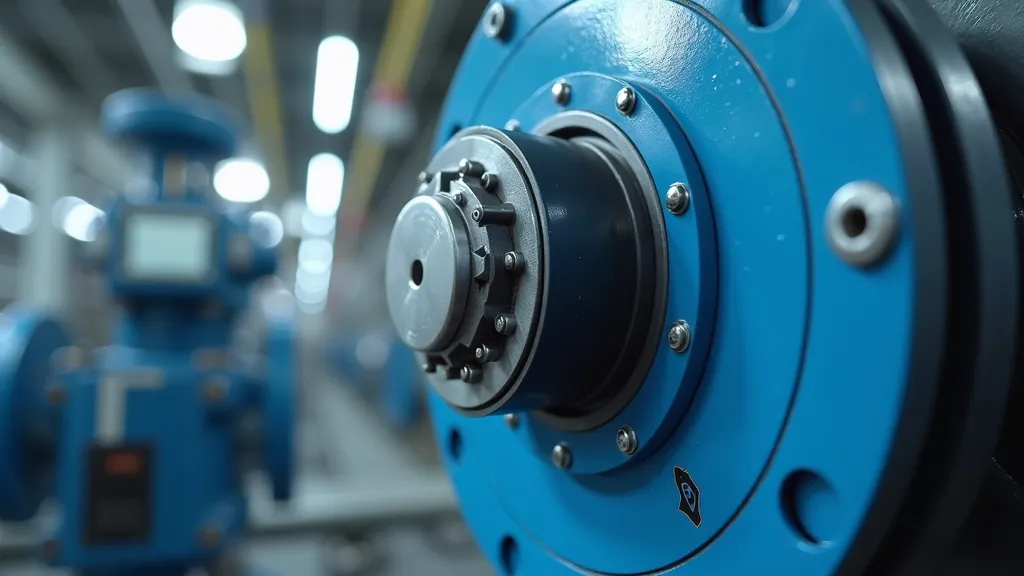

Rexroth servo valves are pivotal in the realm of industrial automation, offering unparalleled precision and control in hydraulic systems. These components are integral to systems requiring meticulous regulation of fluid flow and pressure, thereby ensuring optimal performance in various applications. The seamless integration of Rexroth servo valves in machinery underscores their importance in enhancing efficiency and reliability in manufacturing processes. As industries evolve and demand higher levels of automation and precision, the role of servo valves becomes even more critical. The versatility of Rexroth servo valves allows them to adapt to a wide range of applications, from simple tasks to complex systems requiring sophisticated control mechanisms.

Functionality and Technical Specifications

At the core of Rexroth servo valves is their ability to modulate flow and pressure with exceptional accuracy. These valves operate by converting electrical signals into mechanical movements, adjusting the flow rate based on system requirements. With advanced feedback systems, Rexroth servo valves ensure that the output is consistent with the input command, minimizing errors and enhancing system responsiveness. This feedback mechanism not only improves the accuracy of operations but also allows for real-time adjustments, making them ideal for dynamic environments where conditions can change rapidly.

Technical specifications of Rexroth servo valves include a range of flow capacities, pressure ratings, and electrical configurations, catering to diverse industrial needs. Their robust design and high-quality materials make them suitable for demanding environments, ensuring durability and longevity. Furthermore, the precision-engineered components of these valves are designed to withstand harsh conditions, such as high temperatures, corrosive fluids, and heavy vibrations, which are often encountered in industrial settings.

| Specification | Details |

|---|---|

| Flow Capacity | Various options available to suit different system requirements. |

| Pressure Rating | High-pressure tolerance for demanding applications. |

| Electrical Configuration | Compatible with various control systems for seamless integration. |

| Response Time | Fast response times enable quick adjustments and high precision. |

| Temperature Range | Designed to operate effectively across a wide temperature range. |

Applications in Industry

Rexroth servo valves are ubiquitous in industries such as automotive manufacturing, aerospace, and heavy machinery. Their ability to provide precise control over hydraulic systems makes them indispensable in processes requiring high levels of accuracy and repeatability. In the automotive sector, for example, these valves are crucial in assembly lines where precision is paramount. They facilitate tasks such as robotic welding, where the exact positioning of components is required to ensure structural integrity and quality.

Moreover, in aerospace applications, Rexroth servo valves contribute to the precise control of landing gear and flight control systems, where safety and reliability cannot be compromised. The demands of aerospace technology require components that can operate flawlessly under extreme conditions, making the reliability of Rexroth servo valves a significant asset. Their adaptability and performance make them a preferred choice in sectors that prioritize innovation and quality. Additionally, industries such as pharmaceuticals and food processing also rely on these valves to maintain stringent cleanliness and pressure standards, ensuring product quality and safety.

Benefits of Using Rexroth Servo Valves

The advantages of integrating Rexroth servo valves into industrial systems are manifold. These include enhanced precision in fluid control, improved system efficiency, and reduced energy consumption. By optimizing the performance of hydraulic systems, Rexroth servo valves contribute to lower operational costs and increased productivity. Their ability to maintain stable and accurate control of fluid dynamics allows for better performance in applications such as CNC machining, where minute adjustments can lead to significant improvements in product quality.

Additionally, their robust design ensures minimal maintenance requirements, reducing downtime and extending the lifespan of machinery. The adaptability of these valves to various industrial environments also means they can be tailored to meet specific needs, offering a versatile solution for different applications. For instance, customizing the valve settings allows manufacturers to achieve specific operational parameters that suit their unique processes, further enhancing efficiency.

Innovations in Rexroth Servo Valve Technology

As technology advances, so does the design and functionality of Rexroth servo valves. Innovations such as the integration of IoT (Internet of Things) technology into servo valves allow for real-time monitoring and data collection. This capability enables predictive maintenance, where potential issues can be identified before they lead to equipment failure, thus reducing unplanned downtime.

Furthermore, advancements in material science have led to the development of lighter and more durable components, improving the overall performance of servo valves. These innovations not only enhance the operational efficiency but also contribute to sustainability efforts by reducing energy consumption and material waste. The incorporation of smart technologies is paving the way for more intelligent hydraulic systems that can adapt to changing conditions autonomously, making Rexroth servo valves a cornerstone of future industrial automation.

FAQs

Q: What industries benefit significantly from Rexroth servo valves?

A: Industries such as automotive, aerospace, heavy machinery, pharmaceuticals, and food processing benefit significantly from the precision and reliability of Rexroth servo valves.

Q: How do Rexroth servo valves improve system efficiency?

A: By providing precise control over flow and pressure, these valves enhance system performance, leading to reduced energy consumption and operational costs. Their ability to respond quickly to changes in demand ensures optimal resource utilization.

Q: Are Rexroth servo valves suitable for high-pressure applications?

A: Yes, they are designed to withstand high-pressure environments, making them ideal for demanding industrial applications. Their engineering ensures safety and reliability even under extreme conditions.

Q: What maintenance practices are recommended for Rexroth servo valves?

A: Regular inspections and cleaning are recommended to maintain performance. Monitoring the operating conditions and any unusual noises or vibrations can help identify potential issues early.

Rexroth servo valves stand as a testament to innovation and engineering excellence in the realm of industrial automation. Their role in enhancing performance, efficiency, and reliability cannot be overstated, making them a cornerstone in modern manufacturing and technological advancements. As industries continue to evolve and seek greater efficiency and precision, the importance of such advanced components will only grow, leading to further innovations and applications that leverage the capabilities of Rexroth servo valves.

Conclusion

In conclusion, Rexroth servo valves represent a critical component in the landscape of industrial automation. Their precise control capabilities, robust design, and adaptability to various applications contribute significantly to the efficiency and reliability of hydraulic systems. As industries face increasing demands for productivity and quality, the integration of these valves into manufacturing processes will continue to play a vital role.

The ongoing developments in technology, coupled with the push for greater sustainability and efficiency, indicate that Rexroth servo valves will remain at the forefront of industrial innovation. Their ability to evolve alongside technological advancements ensures that they will meet the future needs of industries striving for excellence. Whether in automotive assembly lines, aerospace applications, or complex manufacturing systems, the impact of Rexroth servo valves is profound and far-reaching, shaping the future of industrial automation.