Understanding Rexroth Servo Valves

Rexroth Servo Valves are critical components in modern automation systems, providing precise control over hydraulic fluid flow and pressure. These valves are integral in industries ranging from manufacturing to aerospace, ensuring efficiency and reliability in complex mechanical operations. This article delves into their functionality, applications, and the technological advancements shaping their evolution.

The Role of Rexroth Servo Valves in Automation

Rexroth Servo Valves serve as pivotal devices in the realm of industrial automation, facilitating precise control of hydraulic fluids to manipulate mechanical systems. Known for their reliability and efficiency, these valves are indispensable in sectors such as aerospace, automotive, and manufacturing. Their ability to regulate flow and pressure with high precision allows for seamless operation of complex machinery. The significance of Rexroth Servo Valves extends beyond mere fluid control; they play a crucial role in enhancing the overall productivity and safety of automated systems.

In industrial environments where every second counts, the responsiveness of servo valves can be the deciding factor between operational success and failure. Their quick reaction times and ability to handle rapid changes in system demands make them essential components in high-performance applications. As industries continue to embrace automation, the demand for advanced servo valve technology like that offered by Rexroth is expected to grow exponentially.

Technical Overview of Rexroth Servo Valves

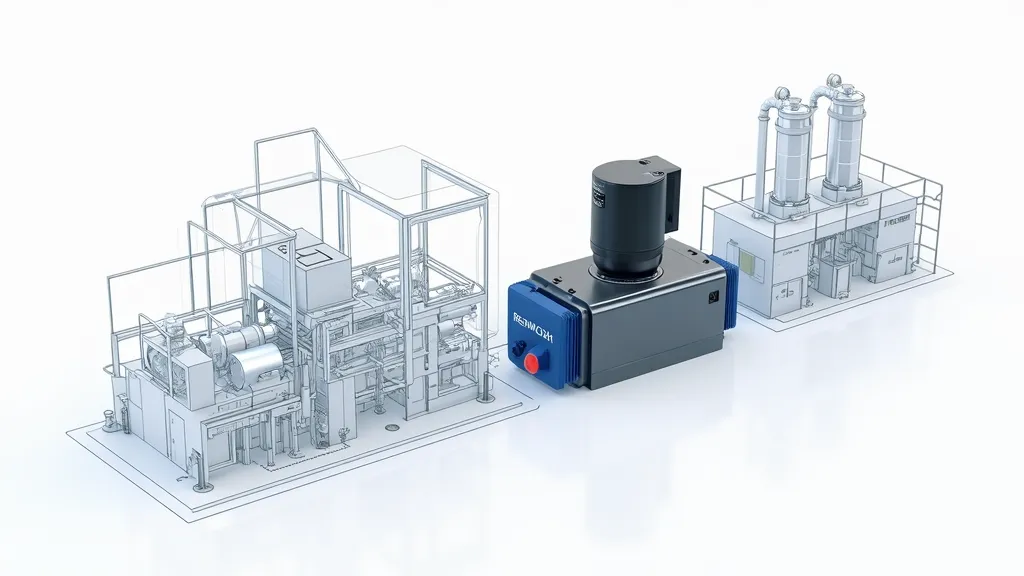

Servo valves are designed to convert electrical signals into hydraulic pressure. The Rexroth Servo Valve, specifically, is renowned for its innovative design, which includes a torque motor, flapper nozzle, and feedback mechanism. These components work in harmony to adjust the position of a spool, thereby controlling fluid flow. This precision is crucial for tasks requiring exact movements and positioning.

The torque motor in Rexroth Servo Valves is a key feature that enables rapid and accurate responses to input signals. It operates by generating a magnetic field that interacts with the valve’s components, allowing for fine-tuning of the fluid flow based on the electrical input received. The flapper nozzle amplifies the torque motor's movement, directing hydraulic fluid more effectively. The feedback mechanism provides real-time data on the valve's position, enabling closed-loop control that enhances overall system performance.

In addition to these components, Rexroth Servo Valves often incorporate advanced electronic controls that can handle complex algorithms. These controls facilitate adaptive adjustments based on changing operational conditions, leading to improved reliability and efficiency in hydraulic systems. The integration of sophisticated control electronics allows for enhanced diagnostics and troubleshooting, further simplifying maintenance and operation.

Applications and Benefits

The versatility of Rexroth Servo Valves makes them suitable for a wide range of applications. In the aerospace industry, for example, they are used in flight control systems to ensure stability and responsiveness. The precision with which these valves operate is vital for maintaining the aerodynamic control of aircraft, where even the slightest deviation can have significant consequences. The automotive sector also benefits from Rexroth Servo Valves, particularly in applications such as active suspension systems and advanced driver-assistance systems (ADAS). These applications require precise control of hydraulic actuators to optimize vehicle performance and safety.

In manufacturing, these valves contribute to the efficiency of automated assembly lines, enhancing productivity and reducing downtime. Automated machines equipped with Rexroth Servo Valves can operate with higher speed and accuracy, which leads to better product quality and lower production costs. Their benefits include improved accuracy, reduced energy consumption, and minimal maintenance requirements.

Moreover, the ability of Rexroth Servo Valves to operate in extreme conditions, such as high temperatures and pressures, further expands their applicability. Industries such as oil and gas, where equipment is often exposed to harsh environments, rely on the robustness and reliability of these valves to ensure uninterrupted operation. This adaptability makes Rexroth Servo Valves a preferred choice for engineers looking for solutions that maintain performance under varying operational stresses.

Technological Advancements

Recent advancements in Rexroth Servo Valve technology have focused on enhancing their digital capabilities. Integration with smart sensors and IoT technology enables real-time monitoring and predictive maintenance, further increasing operational efficiency. The use of advanced materials and manufacturing processes has also led to more durable and lightweight valves. This shift towards digital and smart solutions is part of a larger trend in industrial automation, where connected devices and data analytics are leveraged to optimize performance.

One significant development in Rexroth Servo Valves is the incorporation of machine learning algorithms that allow for predictive maintenance. These algorithms analyze data collected from the valves over time to identify patterns and predict potential failures before they occur. This proactive approach not only reduces unplanned downtime but also extends the lifespan of the equipment, resulting in cost savings for businesses.

Furthermore, advancements in material science have led to the development of new composites that enhance the durability and performance of Rexroth Servo Valves. These materials are designed to withstand corrosive environments and extreme temperatures, ensuring reliability even in the most challenging conditions. The ongoing research into nanotechnology and advanced manufacturing processes promises to unlock even greater potential for future valve designs.

Comparison Table: Traditional vs. Modern Rexroth Servo Valves

| Feature | Traditional Servo Valves | Modern Rexroth Servo Valves |

|---|---|---|

| Control Method | Analog | Digital |

| Monitoring | Manual | Automated, IoT-enabled |

| Material | Standard alloys | Advanced composites |

| Maintenance | Regular, manual | Predictive, automated |

| Response Time | Slower | Faster, real-time |

| Integration Capabilities | Limited | High integration with smart systems |

| Feedback Mechanism | Basic | Advanced, with real-time data |

FAQs

- What industries benefit very from Rexroth Servo Valves?

Industries such as aerospace, automotive, and manufacturing benefit significantly due to the precision and efficiency these valves offer. Additionally, sectors like oil and gas, pharmaceuticals, and robotics also leverage the capabilities of Rexroth Servo Valves for enhanced performance. - How do Rexroth Servo Valves improve system efficiency?

They provide precise control over fluid dynamics, leading to optimized performance and reduced energy consumption. By minimizing energy losses and improving responsiveness, these valves contribute to overall system efficiency and reliability. - Are Rexroth Servo Valves compatible with existing systems?

Yes, they are designed to integrate seamlessly with various hydraulic systems, enhancing their functionality. The modular design of Rexroth Servo Valves allows for easy upgrades and replacements, making them suitable for retrofitting into older systems. - What advancements are expected in the future?

Future advancements may include further integration with AI for enhanced autonomous operation and continued improvements in material science for durability. The development of self-learning systems that can adapt to changing operational conditions is also on the horizon, promising to make Rexroth Servo Valves even more intelligent and efficient.

Conclusion

Rexroth Servo Valves continue to be a cornerstone in the advancement of industrial automation. Their precise control capabilities and adaptability to technological advancements make them indispensable in modern mechanical systems. As industries evolve, these valves will likely remain at the forefront of innovation, driving efficiency and reliability across various applications. The future of Rexroth Servo Valves looks promising, with ongoing research and development aimed at enhancing their performance and expanding their capabilities.

In addition, as the world moves towards more sustainable industrial practices, the energy efficiency of Rexroth Servo Valves positions them as a key component in reducing the carbon footprint of industrial processes. Their ability to minimize energy consumption while maintaining high performance aligns with the global push for greener technologies. Moreover, the integration of smart technology into these valves will enable industries to monitor and optimize their operations in real-time, leading to further improvements in productivity and sustainability.

Overall, the continuous evolution of Rexroth Servo Valves reflects broader trends in automation and technology. Their role in shaping the future of industrial processes cannot be overstated, as they embody the principles of precision engineering and innovative design. As automation becomes increasingly integral to various sectors, Rexroth Servo Valves will undoubtedly play a crucial role in ensuring that these systems operate at peak efficiency and reliability.