The Power of Rexroth Servo Valve

This article delves into the intricacies of the Rexroth Servo Valve, a critical component in precision fluid control across various sectors. The Rexroth Servo Valve is renowned for its precision, efficiency, and adaptability, making it indispensable in industries like manufacturing and automation. Explore its features, benefits, and applications, alongside expert insights into its impact on modern industrial practices.

Understanding Rexroth Servo Valves

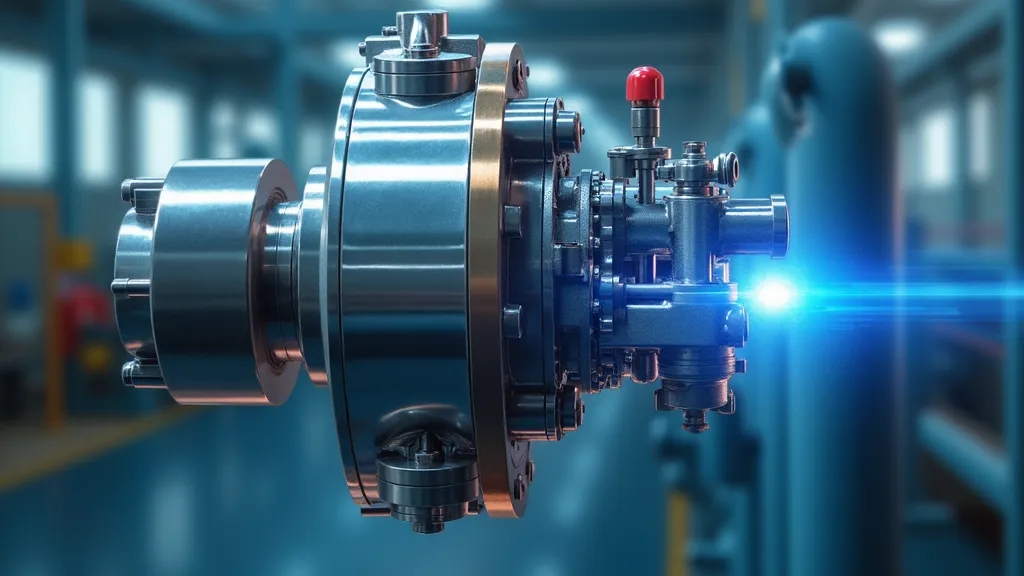

Rexroth Servo Valves are pivotal components in the realm of industrial automation and control. These devices are designed to accurately control the flow of hydraulic fluid, enabling precise movement and positioning within complex machinery. Known for their robustness and precision, Rexroth Servo Valves are utilized extensively in sectors such as manufacturing, aerospace, and automotive production. Their design integrates cutting-edge technology, making them an integral part of hydraulic systems requiring high performance and reliability.

The Importance of Precision in Industrial Applications

In industries where accuracy is paramount, the Rexroth Servo Valve plays an essential role. Its ability to finely modulate fluid flow translates to precise control over mechanical movements, which is crucial for applications ranging from robotic arms to CNC machines. This precision not only enhances the quality of the final product but also optimizes the efficiency of the production process. For instance, in a CNC machine, the exact positioning of tools can mean the difference between a successful cut and a waste of materials. Thus, the reliability of the servo valve directly affects the overall effectiveness of the manufacturing process.

Technical Specifications and Features

Rexroth Servo Valves are engineered with advanced technology to ensure high performance and reliability. Key features include:

- High Responsiveness and Control Accuracy: The servo valves respond rapidly to input signals, allowing for precise adjustments in fluid flow. This responsiveness is crucial in applications where rapid movement is necessary, such as in robotic arms that require quick and accurate positioning.

- Robust Construction for Durability: Built to withstand demanding environments, Rexroth Servo Valves feature durable materials and components that ensure longevity even in harsh conditions. This durability minimizes the risk of failure, which can lead to costly downtimes in production.

- Compatibility with Various Types of Hydraulic Fluids: These valves can operate effectively with a range of hydraulic fluids, making them versatile for different applications and industries. This flexibility allows businesses to select the most suitable hydraulic fluid without compromising the performance of the servo valves.

- Availability in Multiple Sizes and Configurations: Rexroth offers a diverse range of servo valves designed to meet specific application requirements. Whether the need is for a compact valve for tight spaces or a larger valve capable of handling substantial flow rates, Rexroth provides tailored solutions.

Applications Across Industries

The versatility of Rexroth Servo Valves makes them suitable for a wide array of applications. In the automotive industry, they are used in assembly lines for tasks requiring precision. For example, in the assembly of vehicles, servo valves control the hydraulic systems that operate robotic arms, ensuring that components are placed accurately and efficiently. In aerospace, they help in the operation of flight control systems, where even the slightest deviation can impact aircraft safety and performance. The manufacturing sector benefits from their use in machinery requiring exact positioning and velocity control, such as in injection molding machines where precision is critical to producing high-quality products.

Moreover, in the field of renewable energy, such as wind turbine manufacturing, Rexroth Servo Valves control the angle of the blades for optimal energy capture. The ability to adapt to various applications not only showcases their versatility but also highlights the growing demand for precision in modern industrial processes.

Expert Insights on Rexroth Servo Valves

Industry experts emphasize the value of Rexroth Servo Valves in enhancing operational efficiency and reducing downtime. Their reliability and adaptability allow companies to maintain high standards of production while minimizing maintenance costs. For instance, in high-volume production environments, the longevity and reliability of these valves can significantly reduce the frequency of maintenance intervals, thereby increasing overall productivity. As industries continue to evolve towards automation, the role of these servo valves becomes increasingly significant.

Furthermore, experts suggest that the integration of Rexroth Servo Valves with advanced control systems, such as PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition), can enhance their functionality. By incorporating smart technology and real-time monitoring, companies can achieve even greater levels of precision and responsiveness in their operations. This trend towards smart manufacturing is driving the demand for high-performance components like Rexroth Servo Valves.

FAQs

| Question | Answer |

|---|---|

| What is the primary function of a Rexroth Servo Valve? | Its primary function is to control the flow of hydraulic fluid with high precision, enabling accurate movement and positioning in machinery. |

| In which industries are Rexroth Servo Valves very commonly used? | They are commonly used in manufacturing, automotive, aerospace, and other sectors where precision control is vital. |

| What are the benefits of using Rexroth Servo Valves in industrial applications? | The benefits include improved precision, enhanced efficiency, reduced downtime, and lower maintenance costs. |

| Can Rexroth Servo Valves be customized for specific applications? | Yes, they are available in various sizes and configurations to meet specific application requirements. |

| How do Rexroth Servo Valves enhance automation? | By providing precise control over hydraulic systems, they enable automation solutions that require high levels of accuracy and responsiveness, thus improving overall operational efficiency. |

| What maintenance practices are recommended for Rexroth Servo Valves? | Regular inspections, monitoring of fluid quality, and ensuring proper calibration are essential maintenance practices to ensure optimal performance and longevity of the valves. |

Conclusion

Rexroth Servo Valves are indispensable in modern industrial applications, offering unmatched precision and reliability. Their adaptability across various sectors underscores their importance in advancing automation and improving production processes. As industries continue to innovate, the demand for high-quality servo valves like those offered by Rexroth is expected to grow, making them a cornerstone of industrial technology. With the increasing push towards automation and smart manufacturing, the future of Rexroth Servo Valves seems promising, further solidifying their essential role in shaping modern industrial landscapes.

Future Trends in Servo Valve Technology

As technology advances, the future of servo valves, including Rexroth’s offerings, is poised for significant transformation. One of the emerging trends is the integration of IoT (Internet of Things) capabilities into servo valves. By embedding sensors and connectivity features, these valves can provide real-time data on performance and operational status. This data can be invaluable for predictive maintenance, allowing for timely interventions before failures occur, thereby enhancing system reliability.

Moreover, advancements in materials science are leading to the development of lighter, more efficient servo valves. These innovations could further improve their performance, especially in applications where weight and space are critical factors. For instance, in aerospace applications, reducing the weight of components can lead to greater fuel efficiency and improved aircraft performance.

Another significant trend is the move towards energy-efficient hydraulic systems. As industries become more environmentally conscious, the demand for servo valves that can operate efficiently with reduced energy consumption is on the rise. Rexroth is actively working on solutions that not only enhance performance but also contribute to sustainability goals across various sectors.

Case Studies of Rexroth Servo Valve Implementation

To illustrate the impact of Rexroth Servo Valves in real-world applications, several case studies highlight their effectiveness in diverse industries. One such case is in the automotive sector, where a leading manufacturer implemented Rexroth Servo Valves in their robotic assembly lines. By utilizing these valves, they were able to achieve a 25% increase in production speed while maintaining the precision necessary for quality control. The result was a significant reduction in production costs and an increase in overall efficiency.

In another example from the aerospace industry, a company faced challenges with the accuracy of their flight control systems. By integrating Rexroth Servo Valves, they improved the responsiveness of their systems, which not only enhanced safety but also provided better handling characteristics for the aircraft. This case underscores the critical nature of precision in high-stakes environments.

These case studies illustrate not just the versatility of Rexroth Servo Valves but also their capacity to drive innovation and efficiency in various industrial applications. As more companies recognize the benefits of these advanced components, the adoption of Rexroth Servo Valves is likely to grow, leading to even more innovative applications in the future.

The Role of Rexroth in Industry 4.0

As we move deeper into the era of Industry 4.0, the role of Rexroth Servo Valves is becoming increasingly important. Industry 4.0 emphasizes the interconnectivity of machines, systems, and processes, creating smart factories where automation and data exchange are paramount. Rexroth Servo Valves are at the forefront of this transition, providing the precision and reliability needed in interconnected systems.

In smart manufacturing environments, the ability to collect and analyze data from servo valves can lead to insights that drive process improvements. For example, by monitoring the performance of servo valves in real-time, companies can identify inefficiencies and implement corrective actions swiftly. This proactive approach not only enhances productivity but also ensures that machinery operates at optimal levels, reducing wear and tear over time.

Moreover, Rexroth's commitment to developing solutions that integrate seamlessly with digital platforms further positions them as a leader in the transition to smart manufacturing. The company is investing in technologies that allow for better integration of servo valves with other components of the hydraulic system, facilitating smoother operations and enhancing overall system performance.

Conclusion and Looking Ahead

In conclusion, Rexroth Servo Valves are not just components of hydraulic systems; they are critical enablers of precision, efficiency, and innovation in the modern industrial landscape. Their adaptability across various sectors, combined with their robust design and high performance, makes them indispensable in the quest for enhanced automation and productivity. As industries evolve and embrace new technologies, the importance of high-quality servo valves like those from Rexroth will only grow. The future promises exciting developments in servo valve technology, including advancements in IoT integration, energy efficiency, and smart manufacturing, paving the way for even greater innovation in the years to come.