Understanding Rexroth Servo Valves

This guide delves into the intricacies of Rexroth Servo Valves, vital components in hydraulic systems used for precise control of fluid flow and pressure. Known for their reliability and precision, Rexroth Servo Valves are integral to various industrial applications, ensuring efficiency and accuracy in system operations. Explore the engineering marvel behind these valves and their significance in modern machinery.

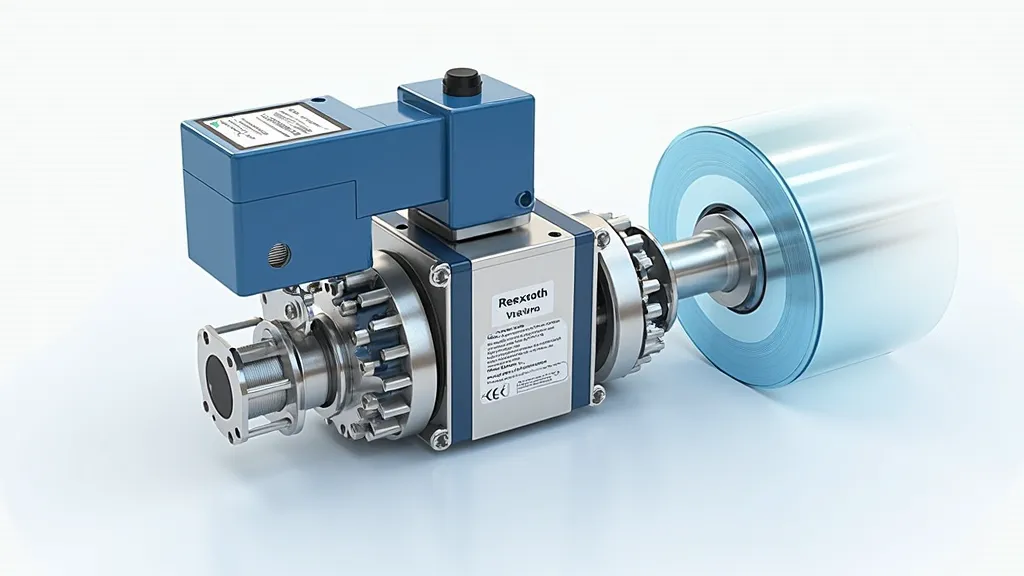

Introduction to Rexroth Servo Valves

Rexroth Servo Valves are renowned for their precision and reliability in controlling fluid dynamics within hydraulic systems. These valves are pivotal in applications requiring accurate flow and pressure modulation, making them indispensable in industries ranging from aerospace to manufacturing. The engineering excellence of Rexroth ensures that their servo valves meet the rigorous demands of modern machinery, facilitating smooth and efficient operations. With an emphasis on innovation and technology, Rexroth Servo Valves are designed to enhance the performance of hydraulic systems, providing enhanced control and efficiency.

The Functionality of Rexroth Servo Valves

At the core of a Rexroth Servo Valve is its ability to modulate hydraulic flow with high precision. This capability is achieved through an intricate design that includes a spool, which moves to adjust the flow area, and an electromagnetic actuator that controls the spool's position. This design allows for rapid response to input signals, ensuring that the hydraulic system can adapt quickly to changing demands. In addition to the spool and actuator, Rexroth Servo Valves often incorporate feedback mechanisms that provide real-time data on the valve's performance, allowing for adjustments that optimize system functionality.

Applications in Various Industries

Rexroth Servo Valves are utilized across a multitude of sectors due to their versatility and precision. In the aerospace industry, they play a crucial role in controlling flight surfaces and landing gear systems, ensuring safety and reliability in flight operations. Manufacturing plants rely on these valves for automated machinery that requires exact movements and positioning, such as robotic arms and CNC machines, where precision is critical to product quality. Additionally, in the automotive sector, they are used in applications like power steering and transmission systems, contributing to improved vehicle performance and safety.

Moreover, Rexroth Servo Valves find applications in the field of robotics, where they enable high-speed and precise control of movements, which is essential for tasks such as assembly, welding, and painting. In the energy sector, these valves are utilized in wind turbines and hydraulic power units, where they help manage the flow of hydraulic fluids, thus optimizing energy production and efficiency. The medical industry also benefits from Rexroth Servo Valves in surgical equipment and diagnostic machines, where precision control is paramount for patient safety and operational effectiveness.

Technical Specifications and Features

Rexroth Servo Valves are designed with advanced features that enhance their performance. These include high-frequency response rates, low hysteresis, and a wide range of flow capacities. The valves are constructed from durable materials to withstand high pressures and demanding operational environments. Moreover, the incorporation of smart technology allows for real-time monitoring and adjustments, further improving system efficiency.

One of the standout features of Rexroth Servo Valves is their ability to handle a variety of fluid types, including oil-based and water-based fluids, without compromising performance. This versatility is crucial in industries where different hydraulic fluids are used, necessitating adaptable components. Additionally, the valves are designed with energy efficiency in mind, helping to reduce the overall energy consumption of hydraulic systems, which is a growing concern in many industries today.

Another critical aspect of Rexroth Servo Valves is their capability to integrate with modern control systems. They can be easily interfaced with PLCs (Programmable Logic Controllers) and other automation technologies, allowing for seamless communication and control. This integration aids in the implementation of advanced automation solutions, such as Industry 4.0 applications, where data exchange and real-time processing are vital for optimal operation.

Comparison Table: Rexroth vs. Competitors

| Feature | Rexroth Servo Valve | Competitor A | Competitor B |

|---|---|---|---|

| Precision | High | Moderate | High |

| Response Time | Fast | Moderate | Fast |

| Durability | Excellent | Good | Excellent |

| Smart Technology | Advanced | Basic | Advanced |

| Flow Capacity | Wide Range | Narrow Range | Moderate Range |

| Ease of Integration | Seamless | Difficult | Moderate |

FAQs

- What makes Rexroth Servo Valves unique? Rexroth Servo Valves are distinguished by their precision, rapid response times, and durability, making them suitable for a wide range of demanding applications. Their advanced technology allows for enhanced control over hydraulic systems, setting them apart from many competitors.

- Can these valves be used in high-pressure environments? Yes, Rexroth Servo Valves are designed to withstand high pressures, making them ideal for industrial applications that require robust performance. Their construction ensures reliability even under extreme conditions, which is essential for industries like aerospace and manufacturing.

- How does smart technology enhance these valves? Smart technology allows for real-time monitoring and adjustments, improving system efficiency and reducing downtime. With integrated sensors and connectivity features, these valves can provide valuable data for predictive maintenance and operational optimization.

- Are Rexroth Servo Valves easy to maintain? Yes, they are designed for ease of maintenance, with readily available parts and comprehensive support from Rexroth. The design of the valves allows for quick access to key components, facilitating routine checks and repairs without significant downtime.

- What industries benefit the most from Rexroth Servo Valves? Industries such as aerospace, automotive, manufacturing, robotics, and energy significantly benefit from the precision and reliability of Rexroth Servo Valves. Their versatility allows them to be adapted for various applications, enhancing operational efficiency across sectors.

- How do Rexroth Servo Valves compare to traditional valves? Unlike traditional valves, which may lack the precision and responsiveness required in modern applications, Rexroth Servo Valves offer advanced features such as real-time feedback, high-speed operation, and integration with automation systems, making them far superior for dynamic environments.

Future Trends in Servo Valve Technology

As industries evolve, so too does the technology surrounding Rexroth Servo Valves. The future of servo valve technology is likely to be shaped by several key trends, including increased automation, the integration of artificial intelligence (AI), and a stronger focus on energy efficiency. Automation is becoming a common theme in manufacturing and production processes, enabling companies to enhance productivity and reduce human error. Rexroth Servo Valves are at the forefront of this trend, providing the precision and control needed for automated systems.

Furthermore, the integration of AI into servo valve technology can lead to smarter systems that can learn and adapt to operational conditions. This means that future servo valves may not only respond to input signals but also analyze data to optimize performance autonomously. Such capabilities can significantly reduce energy consumption and prolong equipment life by ensuring that systems operate within optimal parameters.

A growing focus on sustainability will also influence the development of Rexroth Servo Valves. Manufacturers are increasingly seeking solutions that minimize their environmental impact, and servo valves that are designed for low energy consumption and reduced hydraulic fluid leakage will be in high demand. Innovations in materials and design will enable Rexroth to meet these sustainability goals while maintaining the high performance and reliability that customers expect.

Case Studies: Success Stories with Rexroth Servo Valves

To illustrate the effectiveness of Rexroth Servo Valves, several case studies highlight their successful implementations across various industries. One prominent example is in the aerospace sector, where a leading aircraft manufacturer integrated Rexroth Servo Valves into their flight control systems. The precise control offered by these valves ensured reliable operation of critical flight surfaces, enhancing safety and performance during flight tests. The results were impressive, with reduced response times and improved control accuracy leading to successful certification of new aircraft models.

In the automotive industry, a prominent car manufacturer utilized Rexroth Servo Valves in their robotic assembly lines. These valves allowed for precise control of robotic movements, leading to enhanced assembly accuracy and reduced cycle times. The outcome was a significant increase in production efficiency and a marked improvement in product quality, demonstrating the value of integrating advanced servo technology into manufacturing processes.

Another success story comes from the energy sector, where a renewable energy company employed Rexroth Servo Valves in their wind turbine hydraulic systems. The valves provided exceptional control over the pitch and yaw mechanisms of the turbines, optimizing energy capture and increasing overall efficiency. This implementation not only enhanced energy production but also contributed to the sustainability goals of the company, showcasing the dual benefits of performance and environmental responsibility.

Conclusion

Rexroth Servo Valves represent the pinnacle of hydraulic control technology, offering unmatched precision and reliability. Their application across various industries underscores their versatility and essential role in modern machinery. By choosing Rexroth, industries can ensure optimal performance and longevity of their hydraulic systems, facilitating smoother operations and enhanced productivity. With continuous advancements in technology and a commitment to innovation, Rexroth Servo Valves will remain a vital component in the drive towards more efficient and automated industrial processes.