Understanding Rexroth Servo Valve Functionality

This guide delves into the functionality and importance of Rexroth Servo Valves in industrial automation systems. Rexroth, a leading brand in hydraulic and pneumatic systems, provides precision-engineered servo valves crucial for controlling hydraulic fluid flow. These components are essential in various applications, from manufacturing to aerospace, ensuring efficiency and precision.

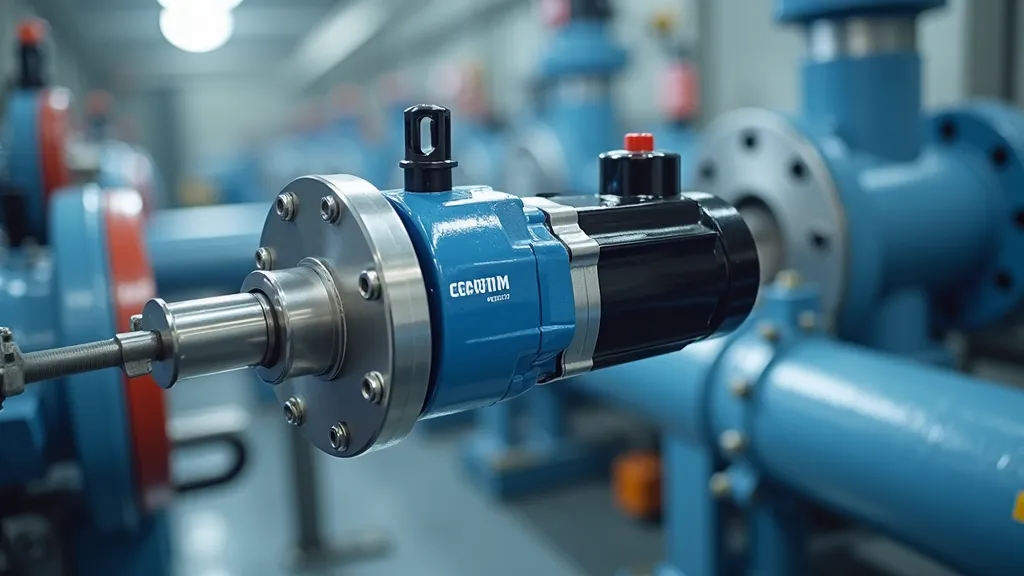

Introduction to Rexroth Servo Valves

The Rexroth Servo Valve is a pivotal component in modern industrial automation systems, renowned for its precision and reliability. As industries increasingly lean towards automation, servo valves, especially those from Rexroth, have become essential in controlling hydraulic fluid flow with unmatched accuracy. Understanding their functionality can greatly enhance the efficiency and effectiveness of various applications. The development of servo technology has revolutionized how machines operate, allowing for finer control and responsiveness. This article delves deeper into the characteristics, operation, and benefits of Rexroth Servo Valves, providing a comprehensive overview.

Core Functionality of Rexroth Servo Valves

Rexroth Servo Valves are engineered to precisely control the flow and pressure of hydraulic fluids within a system. They operate by receiving electrical signals that dictate the positioning of the valve spool, which in turn modulates the hydraulic fluid flow. This capability is critical in applications that demand high precision and responsiveness, such as in CNC machines, aerospace technology, and automotive manufacturing. The fundamental mechanism involves the conversion of electrical signals into mechanical movement, which is achieved through a feedback loop that ensures accuracy. This feedback system continuously monitors the output and adjusts it in real-time, allowing for dynamic control of hydraulic systems.

Detailed Mechanism of Action

The operation of Rexroth Servo Valves is based on the principles of hydraulics and electromagnetism. When an electrical signal is applied to the valve, it activates a coil that generates a magnetic field. This magnetic field moves the valve spool, which alters the flow path of the hydraulic fluid. The spool’s position is continuously monitored through position sensors, ensuring that any deviation from the desired position is corrected instantly. This closed-loop control system is what provides the valves with their remarkable precision and responsiveness.

Moreover, the design of the spool and the orifices within the valve body are meticulously crafted to minimize turbulence and pressure drops, further enhancing the efficiency of the hydraulic system. The materials used in manufacturing these valves contribute to their durability and resistance to wear, making them suitable for high-demand applications.

Applications and Industry Impact

The versatility of Rexroth Servo Valves makes them suitable for a broad spectrum of industries. In manufacturing, these valves enable accurate position control in machinery, ensuring product consistency and reducing waste. In the aerospace sector, they are integral to flight control systems, providing necessary adjustments for safe and efficient aircraft operation. The automotive industry also benefits from their precision in assembly lines and testing equipment.

Beyond these traditional applications, Rexroth Servo Valves are increasingly finding roles in emerging technologies such as robotics and renewable energy systems. In robotics, the precise control of actuators is critical for the accurate movement of robotic arms, enhancing capabilities in automation processes. In renewable energy, these valves are utilized in hydraulic systems for wind turbines, allowing for the fine-tuning of blade angles for optimal energy capture.

Advantages of Choosing Rexroth

Rexroth is a leading brand in the field of hydraulic and pneumatic systems, known for its innovative approach and high-quality products. Their servo valves are characterized by durable construction, high performance, and advanced technology integration. Choosing Rexroth ensures good reliability and optimal performance, making them a preferred choice for industries worldwide. One of the key advantages of Rexroth Servo Valves is their adaptability. They can be customized to meet specific application requirements, allowing for a tailored solution that meets the unique demands of various industries.

Additionally, Rexroth offers extensive support and service, ensuring that clients can optimize their systems for maximum efficiency. This commitment to excellence is reflected in their ongoing investment in research and development, which drives innovation in their product lines. The integration of smart technologies, such as IoT capabilities, further positions Rexroth as a leader in the industry, enabling predictive maintenance and enhanced operational insights.

Comparative Analysis of Servo Valves

| Brand | Features | Applications |

|---|---|---|

| Rexroth | High precision, durable construction, advanced technology | Manufacturing, Aerospace, Automotive |

| Moog | Fast response, robust design, high dynamic performance | Aerospace, Defense, Robotics |

| Parker | Cost-effective, reliable performance, broad application range | Industrial Automation, Agriculture, Marine |

This comparative analysis highlights the strengths of Rexroth Servo Valves against competitors. While Moog is known for its high dynamic performance essential in aerospace and defense applications, Rexroth stands out for its versatility and adaptability across a wider range of industries. Parker, while cost-effective, often targets applications where performance requirements are not as stringent, making Rexroth the preferred choice for high-precision tasks.

Technological Innovations in Rexroth Servo Valves

Rexroth has continuously pushed the boundaries of technology in the field of servo valves. The incorporation of digital electronics and advanced algorithms has allowed for more sophisticated control strategies. For instance, the development of adaptive control systems enables these valves to automatically adjust their response characteristics based on changing load conditions, ensuring optimal performance at all times.

Moreover, the integration of condition monitoring technologies empowers users to maintain their systems proactively. Sensors embedded within the servo valves can detect wear, temperature fluctuations, and other critical parameters, providing data that can be used for predictive maintenance. This approach not only increases the lifespan of the valves but also minimizes downtime, significantly enhancing operational efficiency.

Frequently Asked Questions

- What makes Rexroth Servo Valves stand out?

Rexroth valves are renowned for their precision and reliability, backed by extensive research and development, ensuring they meet the demanding needs of modern industries. - How can these valves improve manufacturing processes?

By providing precise control over hydraulic systems, Rexroth Servo Valves help improve product quality, reduce waste, and enhance overall efficiency. - Are Rexroth Servo Valves suitable for aerospace applications?

Yes, their precision and reliability make them ideal for critical applications like aircraft flight control systems. - What types of maintenance do Rexroth Servo Valves require?

Regular inspection and monitoring are recommended. The use of condition monitoring technologies can help predict maintenance needs, allowing for timely interventions. - Can Rexroth Servo Valves be integrated into existing systems?

Yes, these valves can be customized and adapted to work with a variety of existing hydraulic systems, making them a flexible choice for upgrades.

Conclusion

Rexroth Servo Valves are integral to the advancement of industrial automation, offering unmatched precision and reliability. As industries continue to evolve, the demand for such high-performance components will only increase, solidifying Rexroth's position as a leader in hydraulic and pneumatic systems. By understanding and implementing these valves, businesses can achieve greater efficiency, safety, and innovation in their operations. The continuous advancements in technology and the robust support offered by Rexroth further enhance the value of these components, making them essential for any modern industrial environment. As automation becomes more pervasive, the role of servo valves in enhancing operational capabilities will undoubtedly grow, affirming Rexroth's commitment to excellence in engineering.