Understanding Rexroth Servo Valves

This article delves into the intricacies of Rexroth Servo Valves, highlighting their significance in modern industries. Known for their precision and reliability, these valves play a crucial role in controlling hydraulic systems across various sectors. From enhancing efficiency to ensuring safety, Rexroth Servo Valves are integral to advanced engineering solutions.

Introduction to Rexroth Servo Valves

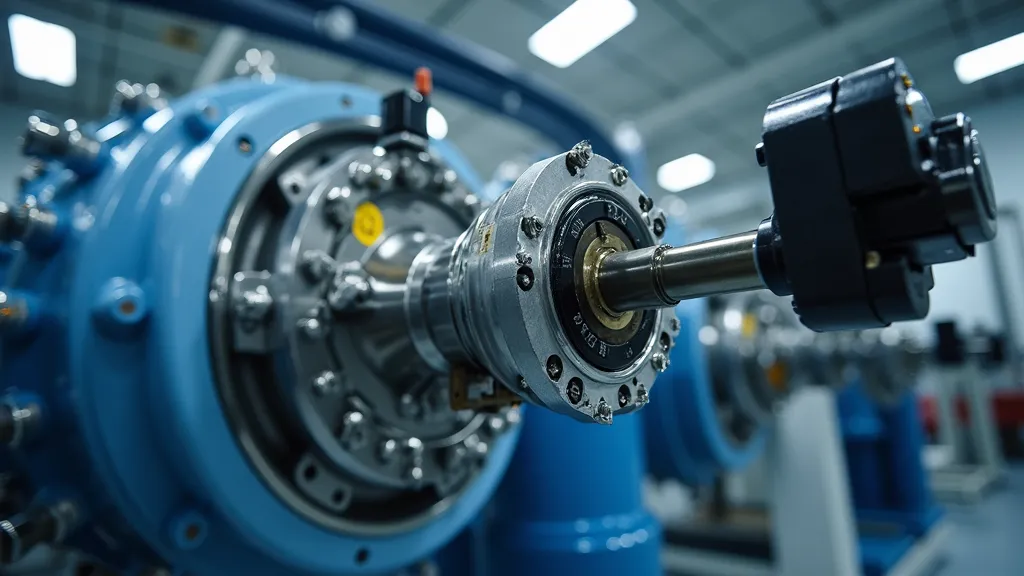

Rexroth Servo Valves are at the forefront of hydraulic control technology, offering unmatched precision and efficiency in a multitude of industrial applications. Renowned for their robustness and adaptability, these valves are engineered to meet the rigorous demands of contemporary engineering systems, ensuring optimal performance and reliability. As industries increasingly rely on automation and precise control mechanisms, the importance of servo valves, particularly those manufactured by Rexroth, cannot be overstated. Their innovative design and advanced technology position them as a key solution for modern hydraulic systems.

The Role and Functionality of Servo Valves

Servo valves are critical components in hydraulic systems, serving as the control element that adjusts the flow of hydraulic fluid, thereby influencing the motion and force of actuators. Their ability to modulate fluid flow with high accuracy makes them indispensable in applications requiring precise control, such as aerospace, automotive, and manufacturing industries. The functionality of a servo valve is pivotal in converting electrical signals into mechanical movement, thus controlling the direction, speed, and force of hydraulic actuators. This conversion process is achieved through the manipulation of hydraulic pressure, which is finely tuned by the servo valve to meet the specific demands of the application.

Key Features of Rexroth Servo Valves

- Precision Control: Rexroth Servo Valves offer unparalleled control precision, which is essential for applications that demand exact movement and positioning. This precision is typically achieved through advanced feedback mechanisms that ensure real-time adjustments to the hydraulic flow.

- Robust Design: These valves are built to withstand harsh industrial environments, ensuring longevity and consistent performance. The materials used in their construction are selected for their resistance to wear, corrosion, and extreme temperatures, making them reliable in varied settings.

- Flexible Integration: Designed with adaptability in mind, Rexroth Servo Valves can be seamlessly integrated into existing systems, enhancing operational efficiency without extensive modifications. This flexibility allows industries to upgrade their systems without the need for complete overhauls, reducing downtime and costs.

- Energy Efficiency: By precisely controlling fluid flow, these valves contribute to reduced energy consumption, which is a critical factor in sustainable industrial practices. Rexroth Servo Valves utilize advanced technology to minimize energy loss, ensuring that the system operates at peak efficiency.

Applications Across Industries

Rexroth Servo Valves are utilized in various sectors, each benefiting from their unique capabilities. The versatility of these valves allows them to be adapted for a wide range of applications, enhancing their appeal across different industries:

- Aerospace: In the aerospace industry, servo valves are crucial for the precise control of flight control surfaces and landing gear systems. Their reliability and responsiveness are essential, as even minor errors in hydraulic systems can lead to significant safety risks.

- Automotive Manufacturing: These valves ensure the smooth operation of robotic arms and assembly line equipment, enhancing production efficiency. In automotive production, where speed and accuracy are paramount, Rexroth Servo Valves help maintain high standards of quality and throughput.

- Industrial Machinery: Servo valves play a vital role in controlling heavy machinery and equipment, ensuring safety and precision in operations. This includes applications in manufacturing plants where automated systems require precise hydraulic control to operate safely.

- Oil and Gas: In this sector, servo valves are used to manage drilling operations and ensure the safe and efficient flow of resources. Their ability to handle high-pressure environments makes them ideal for critical operations in oil extraction and processing.

- Machine Tools: In the realm of manufacturing, Rexroth Servo Valves are pivotal in machine tools, providing the necessary control for cutting, drilling, and milling operations. The precision they offer helps to achieve tighter tolerances and improved surface finishes.

- Plastics and Packaging: These valves are used in machinery that produces plastic products and packaging materials, where precise control of temperature and pressure is crucial for product quality.

Comparison with Competitors

| Feature | Rexroth Servo Valve | Competitor A | Competitor B |

|---|---|---|---|

| Control Precision | High | Medium | High |

| Durability | Robust | Moderate | Robust |

| Energy Efficiency | Excellent | Good | Average |

| Integration Flexibility | High | Medium | High |

The comparison highlights Rexroth's strengths in precision and energy efficiency, which are critical factors for industries focused on maximizing productivity while minimizing costs. By examining the features of competing products, it becomes evident that Rexroth Servo Valves consistently outperform in key areas relevant to modern industrial applications.

FAQs

- What are the primary benefits of using Rexroth Servo Valves?

Rexroth Servo Valves provide precise control, robust durability, and energy efficiency, making them ideal for various industrial applications. Their innovative technology ensures that hydraulic systems can operate optimally, which translates to increased productivity and reduced operational costs. - How do Rexroth Servo Valves enhance system performance?

By offering precise control over hydraulic fluid flow, these valves improve the accuracy and efficiency of system operations, leading to enhanced overall performance. This precision allows for better responsiveness and adaptability in dynamic industrial environments. - Are Rexroth Servo Valves suitable for all types of hydraulic systems?

Yes, their flexible design allows for easy integration into various hydraulic systems, making them a versatile choice for many industries. Whether retrofitting an existing system or incorporating them into new designs, Rexroth Servo Valves provide reliable performance across the board. - What maintenance is required for Rexroth Servo Valves?

Regular maintenance of Rexroth Servo Valves is essential to ensure their longevity and performance. This includes routine inspections, cleaning, and timely replacement of worn components. Proper maintenance practices can significantly extend the life of the valves and enhance system reliability. - How do I choose the right Rexroth Servo Valve for my application?

Choosing the right servo valve involves considering several factors, including the specific requirements of the hydraulic system, the type of actuator being used, and the operational environment. Consulting with a Rexroth expert can provide valuable insights to help select the most suitable valve. - What industries are the primary users of Rexroth Servo Valves?

The primary users of Rexroth Servo Valves span a wide range of industries including aerospace, automotive, oil and gas, and manufacturing. Their application in these sectors underscores their versatility and adaptability to various operational needs.

Conclusion

Rexroth Servo Valves stand out in the realm of hydraulic control technology, offering a combination of precision, durability, and efficiency that few can match. Their application across diverse industries underscores their importance in modern engineering solutions, driving advancements in automation and control. As industries continue to evolve, the demand for reliable and efficient components like Rexroth Servo Valves is only expected to grow, highlighting their pivotal role in shaping the future of industrial operations. The integration of these valves into existing systems not only improves performance but also supports sustainable practices by optimizing energy use and reducing waste.

Future Trends in Servo Valve Technology

The landscape of servo valve technology is rapidly evolving, driven by advancements in digitalization, automation, and the growing emphasis on energy efficiency. As industries seek to improve their operational capabilities, several trends are emerging:

- Smart Servo Valves: The integration of IoT technology into servo valves is paving the way for smart valves that can communicate performance metrics in real-time. These smart valves can self-diagnose and provide predictive maintenance alerts, significantly reducing downtime and maintenance costs.

- Increased Energy Efficiency: Future servo valves are expected to incorporate even more advanced materials and designs that enhance energy efficiency. Innovations such as variable frequency drives and energy recovery systems are being explored to further minimize energy consumption.

- Enhanced Control Algorithms: The use of advanced control algorithms, including machine learning techniques, is expected to improve the performance of servo valves. These algorithms can adapt to changing conditions in real-time, optimizing valve response and fluid flow for varying operational needs.

- Miniaturization: As industries move towards smaller and more compact machinery, the trend towards miniaturizing servo valves is becoming increasingly important. Smaller valves can lead to lighter machinery, which is especially beneficial in applications like aerospace and automotive.

- Environmentally Friendly Alternatives: The push for greener technologies is leading to the development of servo valves that utilize biodegradable hydraulic fluids and sustainable materials. This trend aligns with global efforts to reduce the environmental impact of industrial operations.

Conclusion on Future Trends

The future of Rexroth Servo Valves and servo valve technology, in general, looks promising as these trends emerge. With the continuous push for innovation, Rexroth is likely to remain a leader in the hydraulic control technology space, meeting the evolving needs of various industries. As companies increasingly prioritize efficiency, sustainability, and automation, Rexroth Servo Valves will play a crucial role in driving these advancements, ensuring that industries can operate effectively in a competitive landscape.