Understanding Rexroth Servo Valve Applications

This guide explores the pivotal role of Rexroth Servo Valves in modern industrial automation systems. Known for their precision and reliability, these valves are integral to controlling fluid dynamics in various applications. Originating from Bosch Rexroth, a leader in drive and control technologies, these servo valves offer advanced control solutions that enhance the efficiency and accuracy of hydraulic systems across multiple industries.

Introduction to Rexroth Servo Valves

In the realm of industrial automation, where precision and reliability are paramount, Rexroth Servo Valves stand out as essential components. Originating from Bosch Rexroth, a global leader in drive and control technologies, these valves are renowned for their ability to precisely regulate hydraulic fluid flow and pressure. This precision is crucial in applications ranging from manufacturing to aerospace, where exact control can significantly impact performance and safety. With their advanced capabilities, Rexroth Servo Valves play a critical role in enhancing operational efficiency, reducing waste, and improving overall system performance.

The Role of Rexroth Servo Valves in Automation

Servo valves, such as those from Rexroth, are vital in controlling actuators that move and position machine elements. They convert electronic control signals into movements by modulating the flow of hydraulic fluid. This allows for precise control over mechanical systems, ensuring operations can be carried out with high accuracy and repeatability. Their applications are diverse, including robotics, machine tools, and any system requiring exact fluid control. In robotics, for instance, Rexroth Servo Valves enable smooth and precise movement of robotic arms, enhancing their ability to perform intricate tasks that require high degrees of accuracy.

Technical Insights

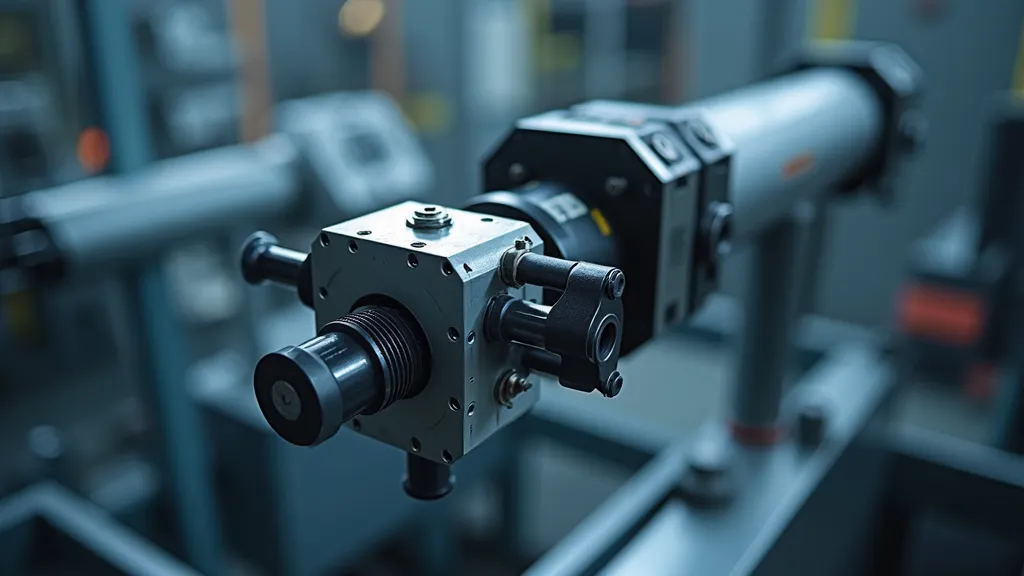

Rexroth Servo Valves are engineered with a focus on reliability and precision. They feature robust construction to withstand harsh industrial environments and advanced technology to ensure responsive performance. Key components include a torque motor, a nozzle-flapper assembly, and a feedback mechanism. The torque motor receives electrical signals, which it converts into mechanical motion, adjusting the position of the nozzle-flapper and thus the flow of fluid through the valve. This interaction is crucial for maintaining the desired performance characteristics of hydraulic systems.

The feedback mechanism is particularly noteworthy, as it continuously monitors the valve position and adjusts the flow accordingly, ensuring that any deviations from the desired output are quickly corrected. This closed-loop control system is what sets Rexroth Servo Valves apart from conventional valves, enabling them to deliver superior performance in dynamic environments.

| Component | Function |

|---|---|

| Torque Motor | Converts electrical signals into mechanical motion. |

| Nozzle-Flapper Assembly | Modulates fluid flow by adjusting the flapper position. |

| Feedback Mechanism | Ensures precise control by monitoring and adjusting valve position. |

| Hydraulic Fluid | Transmits power and aids in the operation of the valve. |

| Control Electronics | Processes input signals and provides output to the torque motor. |

Applications Across Industries

Rexroth Servo Valves are utilized in a wide array of industries. In aerospace, they help in the precise control of flight surfaces, enhancing aircraft stability and performance. The hydraulic systems in aircraft rely on these valves to ensure that all movements, from landing gear deployment to wing adjustments, occur smoothly and reliably. In the automotive industry, they contribute to the precision of manufacturing processes, improving quality and efficiency. For example, in the assembly of vehicles, Rexroth Servo Valves enable precise control of robotic arms that perform welding and painting tasks with high accuracy.

Additionally, they are crucial in the energy sector, where they manage the flow of fluids in power generation systems, ensuring operational reliability and efficiency. In hydroelectric power plants, for instance, these valves control turbine operations, optimizing energy output while maintaining system integrity. The pharmaceutical industry also benefits from Rexroth Servo Valves in processes that require stringent control over fluid dynamics, such as drug manufacturing and packaging, where even the slightest variation can affect product quality.

Advantages of Implementing Rexroth Servo Valves

The implementation of Rexroth Servo Valves offers several advantages. Their high precision improves product quality and process efficiency. The durability of these valves ensures long service life and minimal downtime, reducing maintenance costs. Furthermore, their adaptability to various control systems makes them a flexible choice for many applications, supporting both new installations and upgrades of existing systems. The ability to integrate with various control architectures, whether analog or digital, means that they can be easily incorporated into modern automation setups.

Moreover, Rexroth Servo Valves are designed to handle a broad range of hydraulic fluids, including those with high viscosities. This versatility allows industries to choose the most suitable fluids for their specific applications, further enhancing the performance and efficiency of the systems in which these valves operate. Another significant advantage is their energy efficiency; by optimizing fluid flow, they can help reduce energy consumption and operational costs, making them an attractive choice for businesses seeking to improve their bottom line while implementing sustainable practices.

Installation and Maintenance Considerations

When it comes to installation, proper placement and alignment of Rexroth Servo Valves are critical to their performance. They should be installed in a manner that allows for easy access for maintenance and inspection. It is essential to follow the manufacturer's guidelines during installation to ensure optimal performance and longevity of the valves. Furthermore, the surrounding environment must be taken into account; for instance, valves should be protected from extreme temperatures and contaminants that could hinder their operation.

Maintenance practices are vital to ensuring the longevity and effectiveness of Rexroth Servo Valves. Regular inspections and cleaning, along with timely replacement of worn components, are recommended to maintain optimal performance. Operators should establish a routine maintenance schedule that includes checking for leaks, monitoring fluid levels, and assessing the condition of the hydraulic fluid itself. Additionally, keeping an eye on the performance metrics of the valves—such as response times and flow rates—can help identify potential issues before they become significant problems.

Innovations in Rexroth Servo Valve Technology

As technology continues to advance, Rexroth Servo Valves are undergoing significant innovations, incorporating features that enhance their functionality and adaptability. One such innovation is the integration of smart technology, enabling real-time monitoring and diagnostics. This allows operators to access data related to valve performance, which can be analyzed to improve operational efficiency and predict maintenance needs, ultimately leading to reduced downtime and increased productivity.

Another area of innovation is the development of more compact and lightweight valve designs. These new designs facilitate easier installation and integration into existing systems, making them ideal for applications where space is limited. Additionally, advancements in materials science have led to the creation of more durable components that can withstand the rigors of industrial environments while maintaining high levels of performance.

Furthermore, the trend towards automation and Industry 4.0 has seen Rexroth Servo Valves being increasingly utilized in interconnected systems. By enabling seamless communication between different components of a hydraulic system, these valves can contribute to a more cohesive and efficient operation. This interconnectedness allows for enhanced data collection and analysis, facilitating more informed decision-making and process optimization.

Common Challenges and Solutions

While Rexroth Servo Valves are designed to operate reliably in various conditions, they can still face challenges that may affect performance. One common issue is contamination within the hydraulic system, which can lead to valve malfunction or reduced efficiency. To combat this, regular filtration and maintenance of the hydraulic fluid are essential. Implementing high-quality filters and ensuring proper fluid management can significantly reduce the risk of contamination.

Another challenge is the potential for wear and tear on the components of the servo valve, particularly in high-demand applications. To mitigate this, businesses should consider using wear-resistant materials in valve construction and establish routine maintenance protocols that include the inspection and replacement of critical components. Additionally, training personnel on the proper operation and maintenance of these valves can help prevent misuse and extend their lifespan.

FAQs

- What is the primary function of a Rexroth Servo Valve?

It modulates fluid flow and pressure in hydraulic systems, allowing precise control of mechanical movements. - How do Rexroth Servo Valves differ from other servo valves?

They are distinguished by their advanced engineering, reliability, and the integration of cutting-edge technology, ensuring superior performance. - Can Rexroth Servo Valves be used in high-temperature environments?

Yes, they are designed to operate efficiently in a variety of challenging conditions, including high temperatures. - What maintenance practices are recommended for these valves?

Regular inspections and cleaning, along with timely replacement of worn components, are recommended to maintain optimal performance. - What industries commonly use Rexroth Servo Valves?

Industries such as aerospace, automotive, energy, and pharmaceuticals commonly utilize these valves for their precision and reliability. - How do Rexroth Servo Valves contribute to energy efficiency?

By optimizing fluid flow, they help reduce energy consumption in hydraulic systems, leading to lower operational costs. - Are there any specific training programs for operating Rexroth Servo Valves?

Yes, Bosch Rexroth offers training programs that cover the fundamentals of servo valve operation, maintenance, and troubleshooting.

Conclusion

Rexroth Servo Valves are indispensable in modern industrial automation, offering unrivaled precision and reliability. Their application across various industries underscores their versatility and effectiveness in enhancing system performance. As technology advances, these servo valves continue to evolve, incorporating new features that meet the increasing demands of industrial operations. For businesses seeking to optimize their control systems, Rexroth Servo Valves represent a robust and reliable choice.

Moreover, the ongoing innovations in Rexroth Servo Valve technology promise to further enhance their capabilities, making them even more integral to future industrial applications. As industries continue to embrace automation and advanced control techniques, the role of Rexroth Servo Valves will only become more prominent, driving efficiencies and enabling new levels of performance across a broad spectrum of applications. Businesses that invest in these valves can expect significant returns in terms of efficiency, reliability, and overall operational excellence, ensuring they remain competitive in an ever-evolving market.

With their unmatched precision, durability, and adaptability, Rexroth Servo Valves are not merely components of hydraulic systems; they are essential enablers of modern industrial operations, shaping the future of automation and control technology. As sectors evolve and embrace new technologies, the importance of high-performance components like Rexroth Servo Valves will undoubtedly increase, solidifying their place as a cornerstone of efficient and effective industrial processes.