Understanding Rexroth Servo Valve Systems

The Rexroth Servo Valve is a critical component in modern hydraulic systems, offering precise control for various industrial applications. These valves are known for their reliability, efficiency, and ability to improve system performance. This article explores the intricacies of Rexroth Servo Valves, providing insights into their functions, benefits, and applications across different sectors.

Introduction to Rexroth Servo Valves

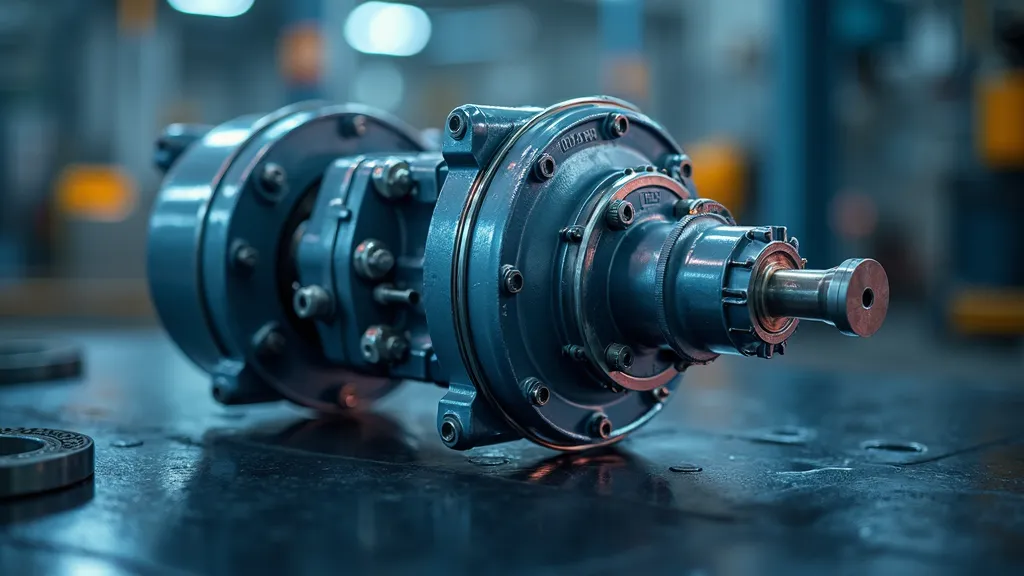

In the realm of hydraulic systems, the Rexroth Servo Valve stands out for its precision and reliability. These valves are integral components in a wide range of industrial applications, from manufacturing to aerospace. They are designed to regulate the flow and pressure of fluids, ensuring that machinery operates efficiently and effectively. The evolution of hydraulic technology has led to the development of advanced servo valves that not only meet but exceed the demands of modern industrial processes.

The Rexroth Servo Valve leverages cutting-edge technology to provide exceptional performance, making it a preferred choice for engineers and operators alike. As industries strive for increased automation and efficiency, the role of these valves becomes even more crucial. Their ability to facilitate precise motion control and respond accurately to electronic signals has fundamentally transformed hydraulic systems, allowing for streamlined operations and enhanced productivity.

Key Features of Rexroth Servo Valves

Rexroth Servo Valves are renowned for their superior design and engineering. Some of the key features that set them apart include:

- Precision Control: The ability to accurately control fluid flow and pressure makes these valves ideal for applications requiring high precision. This precision is critical in sectors such as robotics and aerospace, where even the slightest deviation can lead to significant operational issues.

- Durability: Constructed with high-quality materials, these valves are built to withstand harsh operational environments. The robust design ensures longevity, which is essential in reducing downtime and maintenance costs.

- Efficiency: By optimizing fluid movement, these valves help reduce energy consumption and improve overall system efficiency. This efficiency not only benefits the environment but also enhances the profitability of operations by lowering energy costs.

- Compact Design: The compact nature of Rexroth Servo Valves allows for easy integration into existing systems without requiring significant modifications. This flexibility is particularly advantageous in retrofitting older machinery with modern technology.

- Intelligent Feedback Mechanism: Many Rexroth Servo Valves incorporate advanced feedback systems that provide real-time data on valve performance and system conditions, enabling proactive maintenance and optimal performance monitoring.

Applications of Rexroth Servo Valves

The versatility of Rexroth Servo Valves allows them to be used in various industries. Here are some notable applications:

- Manufacturing: In automated production lines, these valves ensure smooth and precise movements of machinery, enhancing productivity and quality control. They are critical in applications such as CNC machining, where precision is paramount for producing high-quality parts.

- Aerospace: In aircraft systems, Rexroth Servo Valves contribute to the precise control of hydraulic actuators, essential for safe and efficient flight operations. Their reliability under extreme conditions is vital for aerospace applications, where safety is a top priority.

- Automotive: These valves are used in test rigs and simulators to ensure vehicles meet stringent safety and performance standards. They play a crucial role in the development of advanced driver-assistance systems (ADAS) and autonomous vehicles.

- Robotics: In the field of robotics, Rexroth Servo Valves are employed to control the actuators that enable robotic arms to perform intricate tasks with precision. This application is essential in industries like electronics assembly, where accuracy and speed are critical.

- Marine: In marine applications, these valves control hydraulic systems for steering, stabilizers, and deck machinery, ensuring smooth operations even under challenging conditions.

Benefits of Using Rexroth Servo Valves

Implementing Rexroth Servo Valves in hydraulic systems offers several benefits, including:

- Enhanced System Performance: By providing precise control, these valves optimize the performance of hydraulic systems, leading to improved operational outcomes. The ability to maintain consistent performance under varying load conditions is a significant advantage in dynamic applications.

- Cost Savings: Despite the initial investment, the efficiency and durability of Rexroth Servo Valves result in good cost savings through reduced maintenance and energy consumption. Over time, these savings can offset the initial costs, making them a wise investment for businesses.

- Improved Safety: The reliability of these valves minimizes the risk of system failures, thereby enhancing safety in industrial operations. Their fail-safe designs ensure that even in the event of a malfunction, the system can operate within safe parameters.

- Enhanced Flexibility: The ability to customize and adapt Rexroth Servo Valves for specific applications allows manufacturers to innovate without being constrained by hydraulic limitations.

- Global Support Network: Rexroth offers comprehensive technical support and training resources to ensure that users can maximize the performance and longevity of their servo valves.

Comparison Table: Rexroth Servo Valve Models

| Model | Flow Rate | Pressure Range | Applications |

|---|---|---|---|

| Model A | 10 L/min | Up to 350 bar | Industrial automation |

| Model B | 25 L/min | Up to 400 bar | Aerospace systems |

| Model C | 50 L/min | Up to 500 bar | Automotive testing |

| Model D | 75 L/min | Up to 600 bar | Heavy machinery |

| Model E | 100 L/min | Up to 700 bar | Precision aerospace applications |

FAQs

- What is a Rexroth Servo Valve?

A Rexroth Servo Valve is a device used to control hydraulic fluid flow and pressure in systems requiring precise control. It utilizes electronic signals to achieve highly accurate positioning and speed control. - Where are Rexroth Servo Valves commonly used?

They are used in industries such as manufacturing, aerospace, automotive, robotics, and marine applications for scenarios that demand high precision and reliability. - What are the benefits of using Rexroth Servo Valves?

Benefits include enhanced system performance, cost savings through efficiency, improved safety due to their reliable design, and the flexibility to adapt to various applications. - How do Rexroth Servo Valves work?

Rexroth Servo Valves function by receiving electronic signals from a controller, which dictate the position or speed of an actuator. The valve then adjusts the flow of hydraulic fluid accordingly to achieve the desired motion. - What maintenance is required for Rexroth Servo Valves?

Regular inspection and maintenance are essential to ensure optimal performance. This includes checking for leaks, ensuring clean hydraulic fluid, and verifying that electronic components are functioning correctly.

Conclusion

Rexroth Servo Valves are a cornerstone in the landscape of hydraulic systems, offering unmatched precision and reliability. Their application across various industries underscores their versatility and essential role in modern technology. As industries continue to evolve, the demand for such sophisticated components is likely to grow, making Rexroth Servo Valves a crucial element in future advancements. The ongoing development in servo valve technology, including the integration of IoT capabilities and predictive maintenance features, is set to further enhance their functionality and adaptability.

Looking ahead, the rise of smart manufacturing and Industry 4.0 will likely see Rexroth Servo Valves play an even more significant role in the automation landscape. Their ability to integrate seamlessly with digital systems will enable manufacturers to achieve higher levels of efficiency and responsiveness to market demands. As such, investing in Rexroth Servo Valves is not just a choice for today but a strategic decision for future-proofing operations.

Ultimately, Rexroth Servo Valves exemplify the convergence of reliability, precision, and technological advancement, making them indispensable in the pursuit of excellence in hydraulic control systems. Their ongoing evolution will continue to support industries in achieving greater productivity, safety, and sustainability in the years to come.