Understanding Rexroth Servo Valves

This guide explores the intricacies of Rexroth Servo Valves, essential components in hydraulic systems that offer precision control and reliability. Known for their efficiency and adaptability, these valves are pivotal in various industrial applications, ensuring optimal performance and energy savings. Discover their functionality, benefits, and industry relevance in this comprehensive analysis.

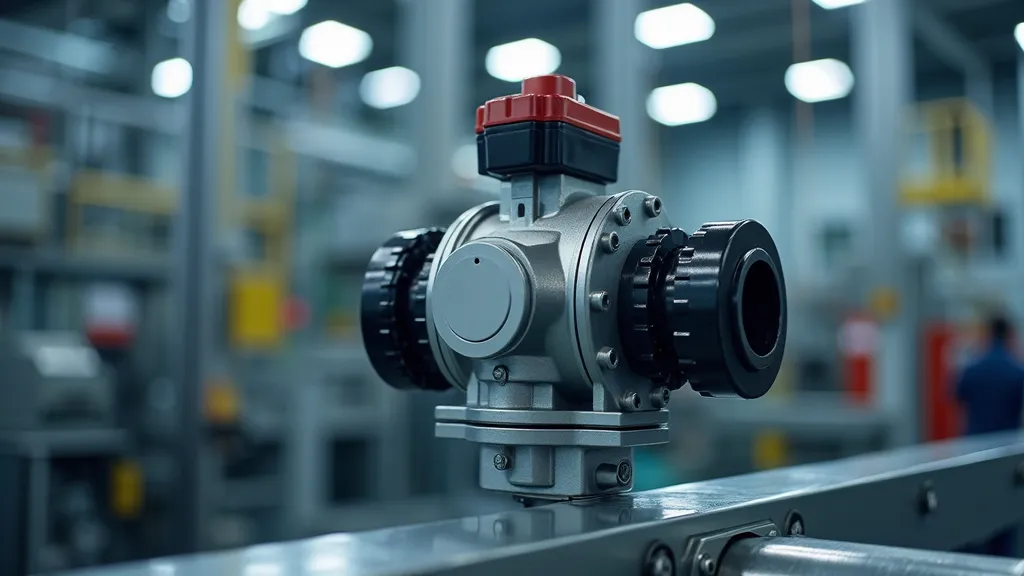

Introduction to Rexroth Servo Valves

Rexroth Servo Valves play a critical role in advanced hydraulic systems, offering unparalleled precision and control. These valves are designed to modulate fluid flow with high accuracy, making them indispensable in industries that demand reliable and efficient automation solutions. From manufacturing to aerospace, Rexroth Servo Valves are known for their durability and performance. They are often cited as the backbone of modern hydraulic systems, enabling applications that require swift adjustments and high responsiveness.

The integration of advanced technology in Rexroth Servo Valves ensures that they not only meet but exceed the evolving demands of industrial automation. The precision engineering involved in their manufacture makes them suitable for high-speed operations and intricate tasks, which are common in today’s fast-paced manufacturing environments. This article will delve deeper into the intricacies of Rexroth Servo Valves, exploring their functionality, benefits, various applications across different industries, and the technology that sets them apart.

The Functionality of Servo Valves

At the core of a Rexroth Servo Valve is its ability to precisely control hydraulic fluid flow and pressure. This is achieved through an intricate system of spools and electromagnetic coils that respond to input signals. By adjusting the position of the spool within the valve body, these components regulate the flow rate and direction, allowing for precise movements in machinery. This precision is crucial in applications where minute adjustments can significantly impact the overall process.

Servo valves operate by interpreting electronic control signals and translating them into mechanical movements. This involves a feedback mechanism, where the position of the actuator is constantly monitored, allowing for real-time adjustments to be made. The closed-loop system ensures that the hydraulic actuator responds accurately to variations in load or pressure, which is essential for maintaining performance in dynamic environments.

Furthermore, the responsiveness of Rexroth Servo Valves is enhanced by their ability to handle rapid changes in input signals. This feature is particularly beneficial in applications that require quick movements and changes in direction, such as robotic arms in manufacturing or flight control surfaces in aerospace. The seamless interaction between the valve and the hydraulic system allows for smooth operation, minimizing the risk of mechanical wear and enhancing the longevity of the equipment.

Key Benefits of Rexroth Servo Valves

- Precision Control: The main advantage of using Rexroth Servo Valves is their ability to provide fine-tuned control over hydraulic systems, which is critical for applications requiring exact positioning and speed. This level of precision helps in achieving desired outcomes consistently, reducing the likelihood of errors in production processes.

- Energy Efficiency: By optimizing fluid flow, these valves help reduce energy consumption, leading to cost savings and a smaller environmental footprint. The implementation of energy-efficient practices is becoming increasingly important in the industrial sector, and Rexroth Servo Valves contribute significantly to these goals.

- Reliability and Durability: Rexroth is renowned for manufacturing robust and durable components, and their servo valves are no exception, offering long service life even in demanding conditions. The materials used in the construction of these valves are selected for their strength and resistance to wear, ensuring they can withstand harsh operating environments.

- Versatility: These valves are adaptable to a wide range of industrial applications, from automotive manufacturing to heavy machinery and beyond. Their versatility allows them to be integrated into various systems, making them a valuable asset for engineers and system designers.

Industry Applications

Rexroth Servo Valves find applications in various sectors, each leveraging the precision and reliability these components offer. In the aerospace industry, they are used for flight control systems where dependability is paramount. The ability to make real-time adjustments to control surfaces is crucial for flight safety and performance, and Rexroth Servo Valves provide the necessary precision for these applications.

In the automotive sector, they assist in robotics and automation processes, enhancing production efficiency. Automated assembly lines rely on the precise control of hydraulic actuators to ensure that components are placed accurately and efficiently. The integration of Rexroth Servo Valves in these systems allows for high-speed operations while maintaining the accuracy required for quality control.

Additionally, these valves are critical in the energy sector, where they help control turbines and other critical machinery. In power plants, for example, the regulation of hydraulic systems that control turbine blades is essential for maximizing efficiency and output. The responsive nature of Rexroth Servo Valves ensures that these systems can adapt to variable loads and conditions, enhancing overall plant performance.

Moreover, in the field of construction equipment, Rexroth Servo Valves are utilized to provide precise control over heavy machinery operations. Whether it’s for lifting, digging, or moving materials, the ability to modulate hydraulic power effectively translates to improved performance and safety on job sites. These characteristics make Rexroth Servo Valves integral to the functioning of modern hydraulic systems.

Comparison Table: Key Features

| Feature | Description |

|---|---|

| Precision | High accuracy in controlling fluid flow and pressure, essential for complex applications. |

| Energy Efficiency | Reduces energy usage by optimizing system performance, contributing to lower operational costs. |

| Durability | Constructed for good use in harsh environments, ensuring long service life. |

| Versatility | Suitable for diverse industrial applications, making them a flexible choice for engineers. |

| Feedback Mechanism | Real-time monitoring of actuator position, allowing for quick adjustments and improved accuracy. |

| Response Time | Quick response to changes in input signals, essential for high-speed applications. |

FAQs

Q: What makes Rexroth Servo Valves stand out in the market?

A: Rexroth Servo Valves are distinguished by their precision, durability, and versatility, making them a preferred choice in various industrial applications. Their advanced design and engineering set them apart from traditional valves, ensuring superior performance.

Q: How do these valves contribute to energy savings?

A: By optimizing hydraulic fluid flow, these valves reduce energy consumption, leading to cost-effective and environmentally friendly operations. This optimization is achieved through precise control of the pressure and flow rate, minimizing wastage.

Q: Can Rexroth Servo Valves be used in different industries?

A: Yes, they are highly adaptable and can be used across numerous sectors, including aerospace, automotive, and energy. Their flexibility allows for integration into a variety of systems, meeting the specific needs of different applications.

Q: What types of systems are compatible with Rexroth Servo Valves?

A: Rexroth Servo Valves can be integrated into hydraulic, pneumatic, and various automation systems. Their compatibility with advanced control systems enhances their functionality and performance across different platforms.

Q: What maintenance is required for Rexroth Servo Valves?

A: Regular maintenance includes checking for leaks, monitoring fluid levels, and ensuring the electrical components are functioning correctly. Preventive maintenance practices can significantly extend the lifespan of these valves and ensure optimal performance.

Technological Advancements in Servo Valve Design

The evolution of Rexroth Servo Valves is closely tied to advancements in technology and engineering practices. Modern servo valves incorporate sophisticated features such as digital signal processing and advanced feedback control algorithms. These innovations enhance their responsiveness and precision, allowing for more complex applications in automation and control systems.

Digital signal processing (DSP) technology allows for better interpretation of input signals, improving the accuracy of fluid flow control. This advancement means that servo valves can now operate with greater efficiency and reliability, reducing the risk of errors commonly associated with analog systems. Furthermore, the implementation of advanced feedback control algorithms provides real-time data analysis, allowing for immediate adjustments to be made based on system performance.

Additionally, the use of smart sensors in conjunction with Rexroth Servo Valves enhances their capability to adapt to changing conditions. These sensors can monitor variables such as pressure, temperature, and flow rate, feeding that information back to the control system. This integration of smart technology not only improves operational efficiency but also contributes to predictive maintenance strategies, where potential issues can be identified before they lead to system failures.

Future Trends in Servo Valve Technology

The future of Rexroth Servo Valves is poised for further innovation as industries continue to demand higher levels of automation and efficiency. One significant trend is the move towards fully automated systems that leverage artificial intelligence (AI) and machine learning (ML) technologies. These systems will utilize data analytics to optimize valve performance and predict maintenance needs, ultimately enhancing reliability and reducing downtime.

Another trend is the increasing focus on sustainability within industrial processes. As industries strive to reduce their carbon footprint and energy consumption, the development of energy-efficient servo valves that minimize fluid loss and optimize power usage will be crucial. Rexroth is already at the forefront of this movement, continuously improving their products to align with environmental goals.

Moreover, the integration of IoT (Internet of Things) technology into servo valve applications is expected to rise. This integration will enable real-time monitoring and control of hydraulic systems remotely, providing operators with detailed insights into system performance and facilitating quicker decision-making processes. The ability to access and analyze data from servo valves in real-time can lead to improved operational efficiencies and reduced operational costs.

Conclusion

Rexroth Servo Valves are a cornerstone in the field of industrial automation, providing the precision and reliability necessary for modern hydraulic systems. Their advanced design and robust construction ensure they meet the rigorous demands of various applications, making them an invaluable asset in any industrial setting. By understanding their operation and benefits, industries can better leverage these components to enhance performance and efficiency.

As we look to the future, the continual evolution of Rexroth Servo Valves will likely include advancements in technology that promote enhanced performance, sustainability, and integration with smart technologies. This evolution not only promises to improve existing applications but also opens the door to new possibilities in automation and control systems. Industries that adopt these innovations will be well-positioned to thrive in a competitive landscape that increasingly values efficiency, precision, and sustainability.